Automatic repair acrylic microgel self-emulsifying emulsion and preparation method thereof

An automatic repair and microgel technology, which is applied in the preparation of microspheres, microcapsule preparations, coatings, etc., can solve the problem that the solid content of acrylic microgel emulsion needs to be increased, the compatibility between the shell layer and the core core is poor, and the coating is affected. Water resistance, acid resistance and other problems, to achieve the effect of reducing the steps of removing organic solvents, high glass transition temperature, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

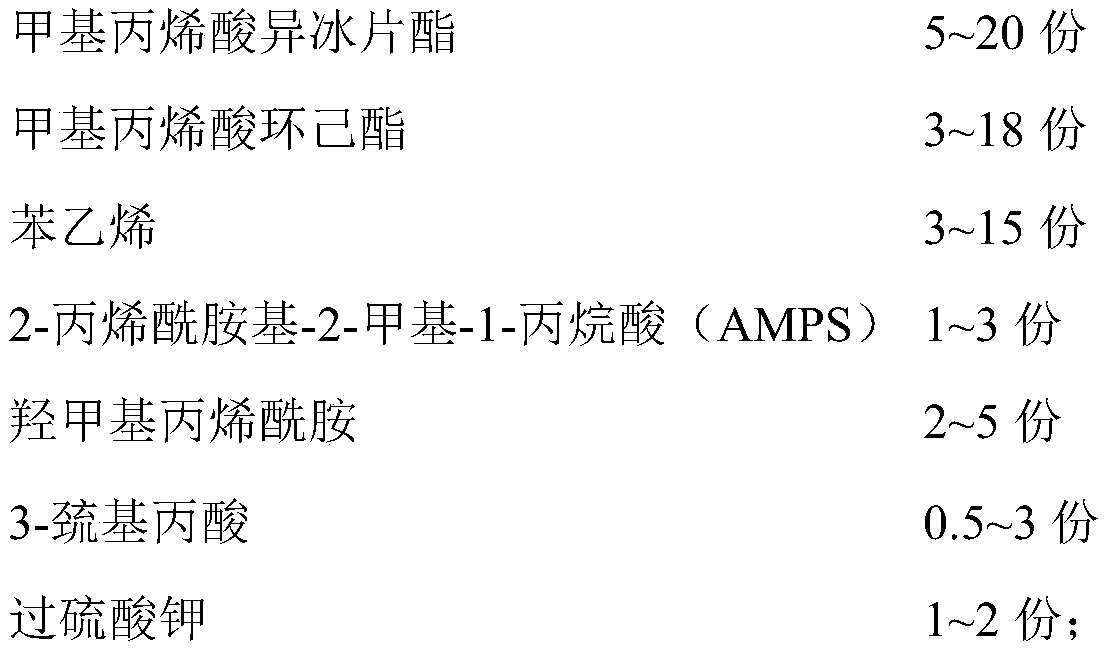

[0043] A self-repairing acrylic microgel self-emulsifying emulsion, the microgel includes a shell and a core, and the shell composition and parts by mass of each component are:

[0044]

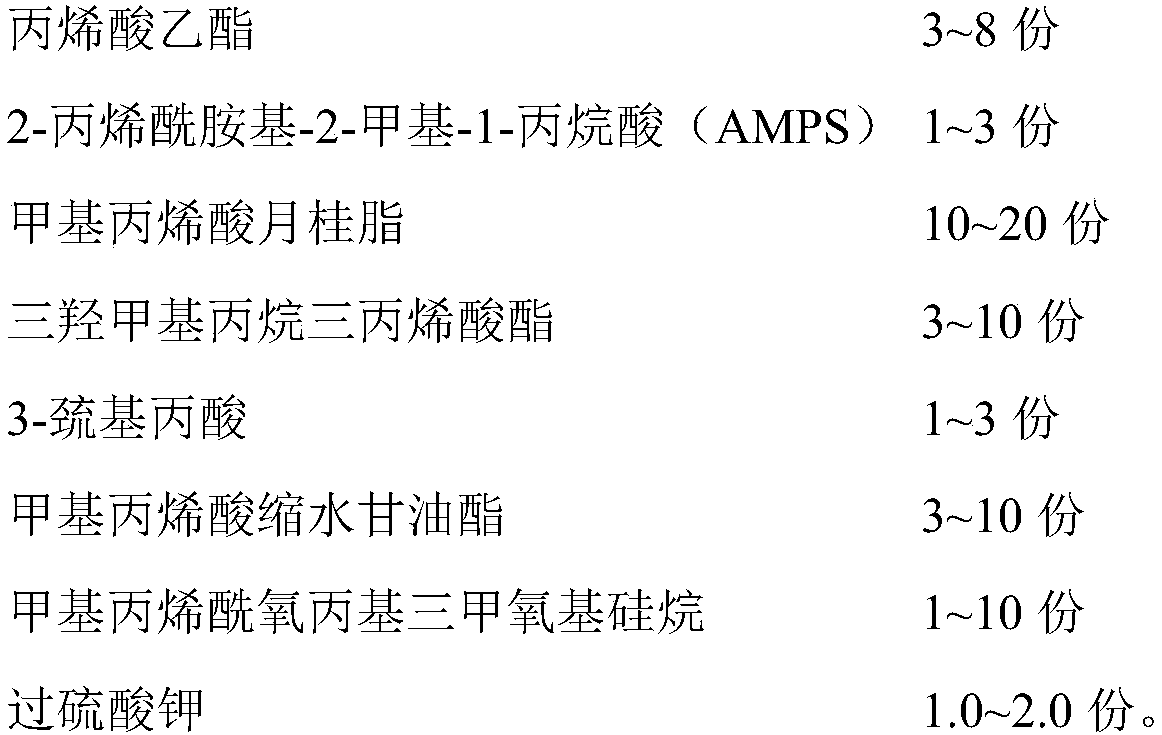

[0045] The composition of the core and the parts by mass of each component are:

[0046]

[0047] A preparation method for self-repairing acrylic microgel self-emulsifying emulsion, the steps are:

[0048] (1) Add 35 parts of water, 0.5 part of Na to the reactor 2 CO 3 , 0.5 parts NaHCO 3 and potassium persulfate to form liquid A, heated to 60°C and kept warm;

[0049] (2) Ethyl acrylate, 3-mercaptopropionic acid, 2-acrylamido-2-methyl-1-propanoic acid (AMPS), lauryl methacrylate, trimethylolpropane triacrylate, methyl Glycidyl acrylate and methacryloxypropyl trimethoxysilane are mixed to obtain a mixture solution B liquid;

[0050] (3) Add liquid B of the mixture solution obtained in step (2) dropwise to liquid A described in step (1), the time for the dropwise addition is 3 hours...

Embodiment 2

[0056] A self-repairing acrylic microgel self-emulsifying emulsion, the microgel includes a shell and a core, and the shell composition and parts by mass of each component are:

[0057]

[0058] The composition of the core and the parts by mass of each component are:

[0059]

[0060] A preparation method for self-repairing acrylic microgel self-emulsifying emulsion, the steps are:

[0061] (1) Add 40 parts of water, 0.75 parts of Na to the reactor 2 CO 3 , 0.75 parts NaHCO 3 and potassium persulfate to form liquid A, heated to 60°C and kept warm;

[0062] (2) Ethyl acrylate, 3-mercaptopropionic acid, 2-acrylamido-2-methyl-1-propanoic acid (AMPS), lauryl methacrylate, trimethylolpropane triacrylate, methyl Glycidyl acrylate and methacryloxypropyl trimethoxysilane are mixed to obtain a mixture solution B liquid;

[0063] (3) Add liquid B of the mixture solution obtained in step (2) dropwise to liquid A described in step (1), the time for adding is 4 hours, keep at 65...

Embodiment 3

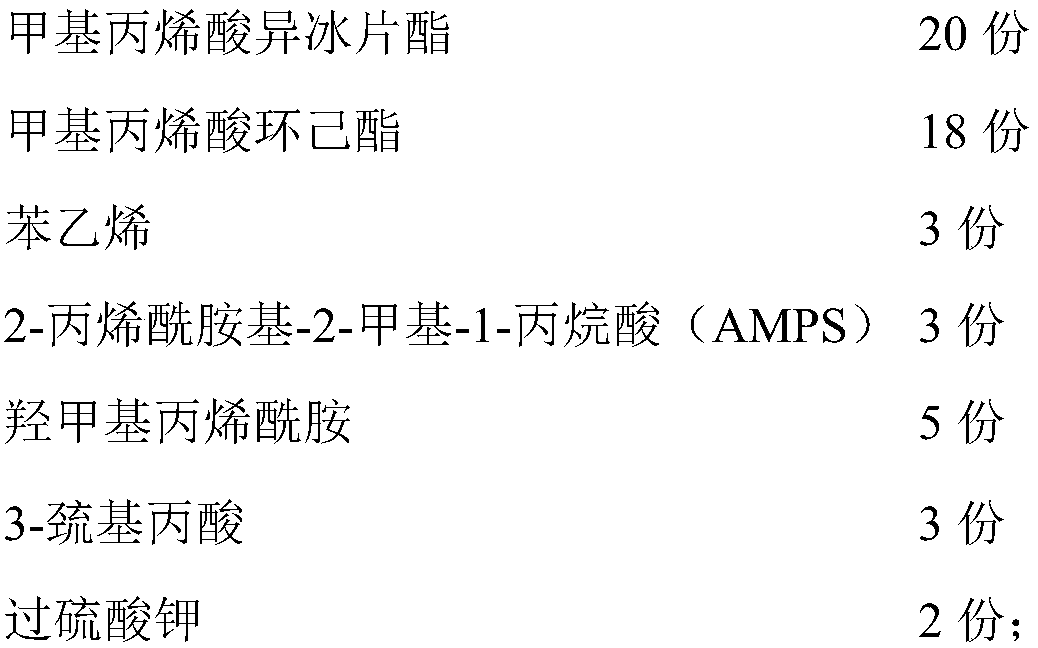

[0069] A self-repairing acrylic microgel self-emulsifying emulsion, the microgel includes a shell and a core, and the shell composition and parts by mass of each component are:

[0070]

[0071]The composition of the core and the parts by mass of each component are:

[0072]

[0073]

[0074] A preparation method for self-repairing acrylic microgel self-emulsifying emulsion, the steps are:

[0075] (1) Add 45 parts of water and 1 part of Na to the reactor 2 CO 3 , 1 part NaHCO 3 and potassium persulfate to form liquid A, heated to 60°C and kept warm;

[0076] (2) Ethyl acrylate, 3-mercaptopropionic acid, 2-acrylamido-2-methyl-1-propanoic acid (AMPS), lauryl methacrylate, trimethylolpropane triacrylate, methyl Glycidyl acrylate and methacryloxypropyl trimethoxysilane are mixed to obtain a mixture solution B liquid;

[0077] (3) Add liquid B of the mixture solution obtained in step (2) dropwise to liquid A described in step (1), the time for adding is 5 hours, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com