A PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability and preparation method thereof

A matting powder and high-permeability technology, which is applied in the field of coatings, can solve the problems of not so clear wood grain, too large silica particles, and poor paint film permeability, so as to improve freeze-thaw property, adhesion, Effect of Chemical Resistance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

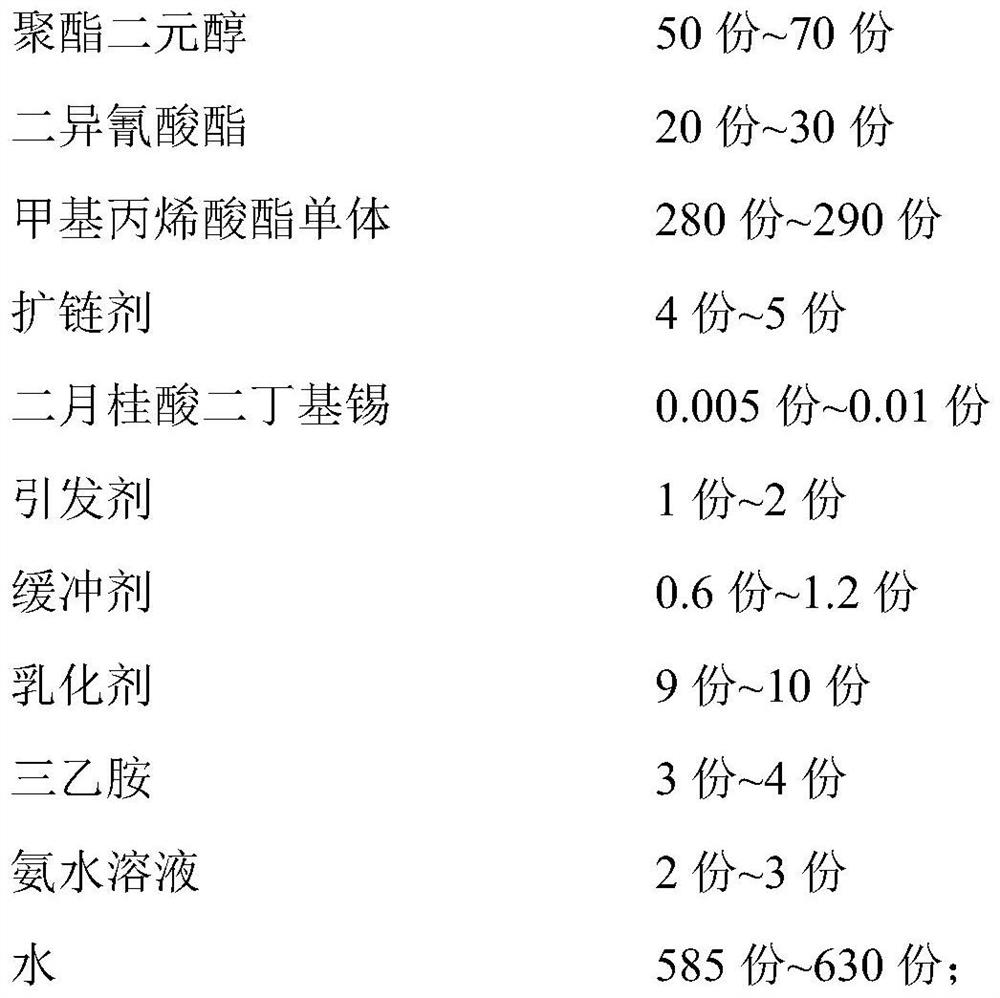

[0047] A PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability, which includes the following raw materials in parts by weight:

[0048]

[0049] The methacrylate monomer comprises the following components in parts by weight:

[0050]

[0051] In this embodiment, the polyester diol is polyethylene adipate diol with a molecular weight of 1000.

[0052] Among them, the diisocyanate is isophorone diisocyanate.

[0053] Wherein, the chain extender is dimethylol propionic acid.

[0054] Wherein, the initiator is ammonium persulfate.

[0055] Wherein, buffering agent is sodium bicarbonate.

[0056] In this embodiment, the mass percent concentration of the ammonia solution is 20%.

[0057] The above-mentioned preparation method of a PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability comprises the following steps:

[0058] Step 1. Preparation of the ...

Embodiment 2

[0066] A PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability, which includes the following raw materials in parts by weight:

[0067]

[0068]

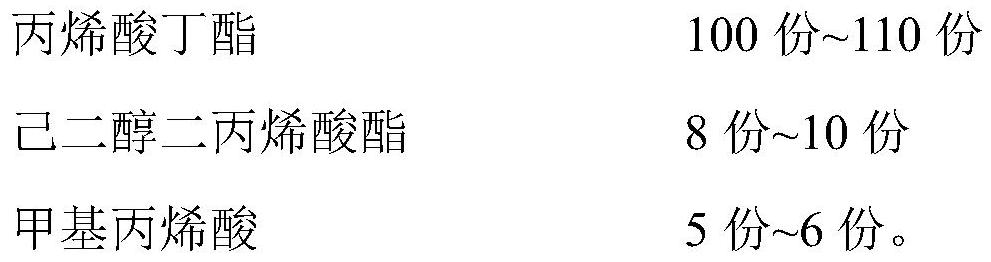

[0069] The methacrylate monomer comprises the following components in parts by weight:

[0070]

[0071] In this embodiment, the polyester diol is polyethylene adipate diol with a molecular weight of 800.

[0072] Among them, the diisocyanate is isophorone diisocyanate.

[0073] Wherein, the chain extender is dimethylol propionic acid.

[0074] Wherein, the initiator is ammonium persulfate.

[0075] Wherein, buffering agent is sodium bicarbonate.

[0076] In this embodiment, the mass percent concentration of the ammonia solution is 15%.

[0077] The above-mentioned preparation method of a PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability comprises the following steps:

[0078] Step 1. Preparat...

Embodiment 3

[0086] A PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability, which includes the following raw materials in parts by weight:

[0087]

[0088] The methacrylate monomer comprises the following components in parts by weight:

[0089]

[0090]

[0091] In this embodiment, the polyester diol is polyethylene adipate diol with a molecular weight of 1500.

[0092] Among them, the diisocyanate is isophorone diisocyanate.

[0093] Wherein, the chain extender is dimethylol propionic acid.

[0094] Wherein, the initiator is ammonium persulfate.

[0095] Wherein, buffering agent is sodium bicarbonate.

[0096] In this embodiment, the mass percent concentration of the ammonia solution is 25%.

[0097] The above-mentioned preparation method of a PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability comprises the following steps:

[0098] Step 1. Prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com