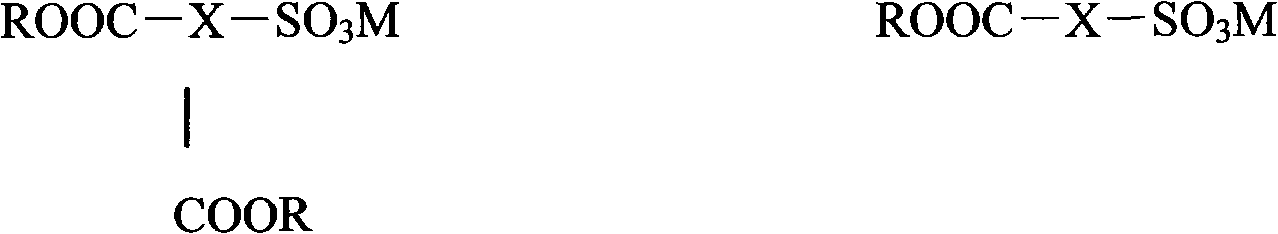

Self-crosslinking sulfonate-base epoxy ester aqueous dispersion and anti-corrosive primer thereof

A technology based on epoxy ester and anti-rust primer, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve the problems of difficult control of the reaction process, poor water resistance of the paint film, and decreased performance of the paint film. Self-crosslinking, paint film densification, and the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example aims to demonstrate the synthesis of aqueous dispersions of sulfonate-based epoxy esters and their preparation methods

[0046] Listed in Table 1 is the synthetic formulation example of the sulfonate-based epoxy ester aqueous dispersion, and Table 2 is the performance index of all sulfonate-based epoxy ester aqueous dispersions corresponding to Table 1.

[0047] The preparation method of listed sulfonate base epoxy ester aqueous dispersion in table 1 is:

[0048] Add the epoxy resin, fatty acid, sulfonate group-containing functional monomer and catalyst into the reaction bottle, and start to heat up after passing nitrogen for 10-20 minutes. When the temperature rises to 100-150°C, the material melts and starts to stir. Continue to heat up to 200-240°C, keep warm for esterification reaction, and then cool down when the acid value is 8-20mgKOH / g. When the temperature drops to 160-180°C, add the formulating amount of co-solvent, and continue to cool down to 3...

Embodiment 2

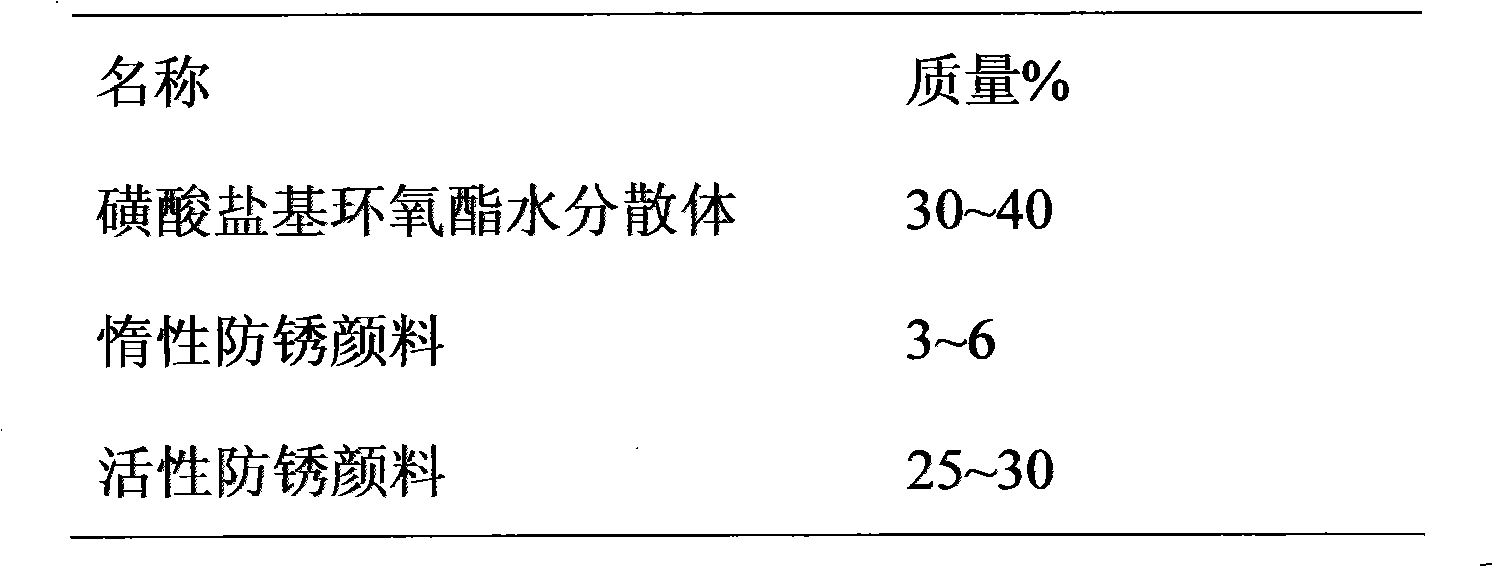

[0055] This example is intended to demonstrate an example formulation of an anti-corrosion primer based on a sulfonate-based aqueous dispersion and its preparation. Listed in table 3 is the formula example of the antirust primer with sulfonate-based epoxy ester aqueous dispersion as base material, and table 4 is that corresponding table 3 takes sulfonate-based epoxy ester aqueous dispersion as base-material Performance indicators of various antirust primers.

[0056] Table 3 takes the sulfonate-based epoxy ester aqueous dispersion as the base material antirust primer formulation example

[0057]

[0058] According to the formula listed in table 3, the method for base material antirust primer with sulfonate base epoxy ester aqueous dispersion is as follows:

[0059] (1) Add the formulated amount of deionized water, dispersant and defoamer to the dispersing kettle, and stir for 15 to 30 minutes at a speed of 600 to 800 rpm to make the materials evenly mixed;

[0060] (2) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com