A kind of water-based imitation coating high elastic stiffening finishing agent and preparation method

A finishing agent and coating technology, which is applied in the field of water-based imitation coating high-elasticity and stiff finishing agent and preparation, can solve the problems of unenvironmental protection, decreased unique hand feel and limited application scope, and achieves excellent washing resistance and meets export requirements. Environmental requirements, the effect of increasing self-crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

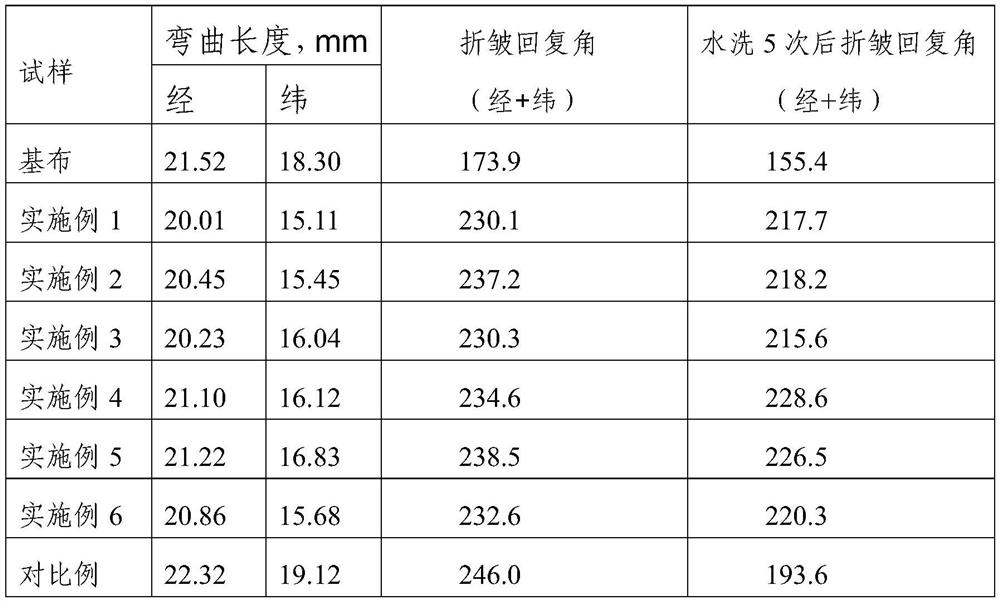

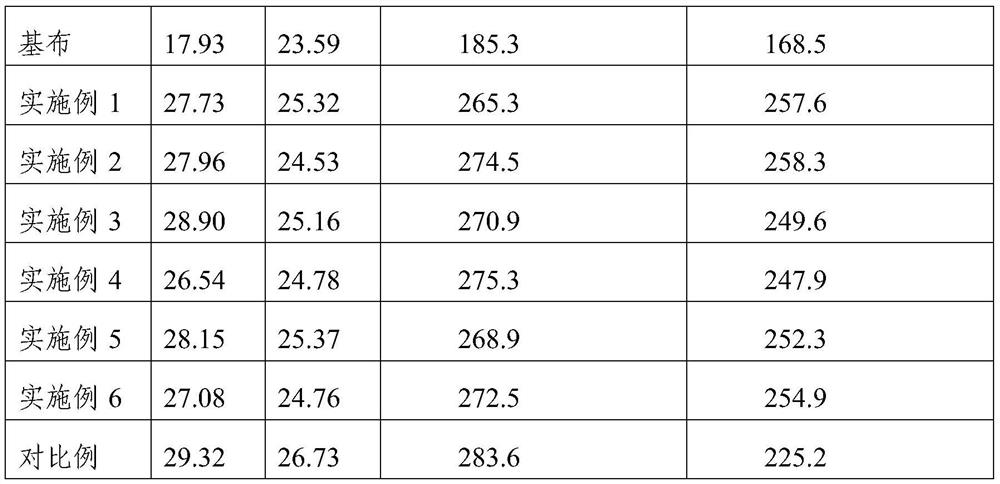

Examples

Embodiment 1

[0030] A water-based imitation coating high-elasticity stiffening finishing agent is prepared from the following raw materials in parts by weight: 50 parts of emulsion A, 100 parts of emulsion B, and 5 parts of cationic blocked isocyanate crosslinking agent; the cationic blocked isocyanate The cross-linking agent was selected from Y-203B of Hefei Aditya Chemical Co., Ltd.

[0031] The emulsion A is prepared from the following raw materials in parts by weight: 100 parts of octamethylcyclotetrasiloxane, 3 parts of silane coupling agent, 3 parts of quaternary ammonium cationic surfactant, and 1 part of peregal 0-10 , 0.1 part of potassium hydroxide, and 220 parts of deionized water; the silane coupling agent is γ-glycidyloxypropyltrimethoxysilane; the quaternary ammonium cationic surfactant is cetyltrimethyl chloride ammonium chloride.

[0032] The emulsion B is prepared from the following raw materials in parts by weight: 100 parts of double-ended epoxy silicone oil, 3.2 parts ...

Embodiment 2

[0040] A water-based imitation coating high-elasticity stiffening finishing agent is prepared from the following raw materials in parts by weight: 60 parts of emulsion A, 100 parts of emulsion B, and 8 parts of cationic blocked isocyanate crosslinking agent; the cationic blocked isocyanate crosslinking agent The joint agent was selected from Y-203B of Hefei Aditya Chemical Co., Ltd.

[0041] The emulsion A is prepared from the following raw materials in parts by weight: 120 parts of octamethylcyclotetrasiloxane, 5 parts of silane coupling agent, 5 parts of quaternary ammonium cationic surfactant, 1 part of peregal 0-10 , 0.12 parts of potassium hydroxide, and 300 parts of deionized water; the silane coupling agent is γ-glycidoxypropyl triethoxysilane; the quaternary ammonium cationic surfactant is octadecyltrimethyl Ammonium chloride.

[0042] The emulsion B is prepared from the following raw materials in parts by weight: 150 parts of double-ended epoxy silicone oil, 9 parts ...

Embodiment 3

[0050] A water-based imitation coating high-elasticity stiffening finishing agent is prepared from the following raw materials in parts by weight: 50 parts of emulsion A, 120 parts of emulsion B, and 10 parts of cationic blocked isocyanate crosslinking agent; the cationic blocked isocyanate The cross-linking agent was selected from Y-203B of Hefei Aditya Chemical Co., Ltd.

[0051] The emulsion A is prepared from the following raw materials in parts by weight: 150 parts of octamethylcyclotetrasiloxane, 5 parts of silane coupling agent, 5 parts of quaternary ammonium cationic surfactant, and 2 parts of peregal 0-10 , 0.15 parts of potassium hydroxide, 350 parts of deionized water; the silane coupling agent is β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane; the quaternary ammonium cationic surfactant is ten Octaalkyltrimethylammonium chloride.

[0052] The emulsion B is prepared from the following raw materials in parts by weight: 150 parts of double-ended epoxy silicone oil, 7.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com