Special environmental-friendly halogen-free flame retardant for ABS (acrylonitrile butadiene styrene) resin

A technology of ABS resin and flame retardant, which is applied in the field of phosphorus-based environmentally friendly flame retardants, can solve the problems of melting dripping and prohibition, and achieve the effect of good char formation, low price, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

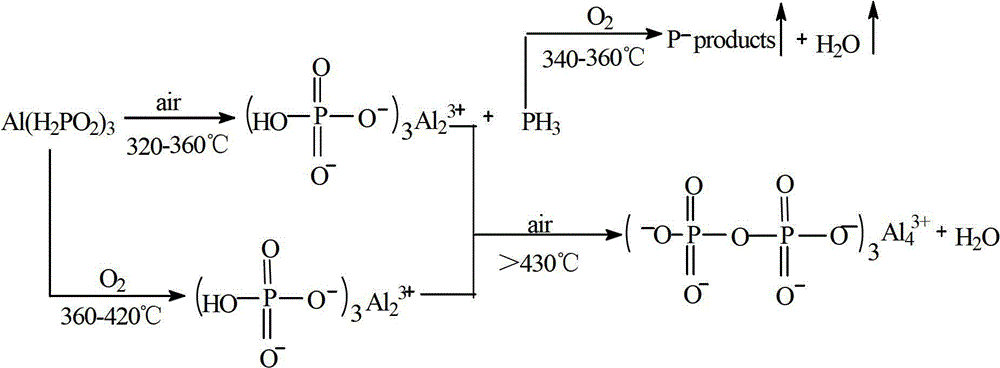

Method used

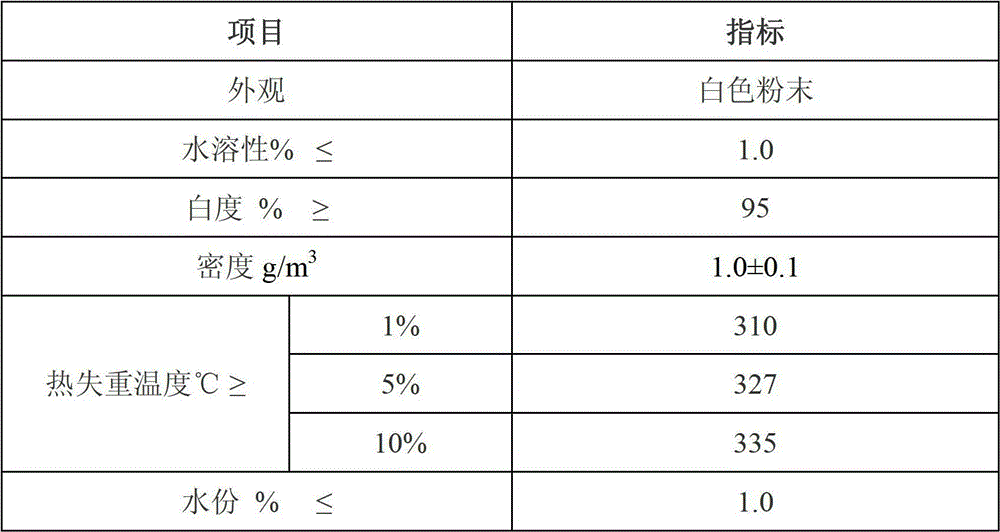

Image

Examples

Embodiment 1

[0017] Proportion (parts by weight): aluminum hypophosphite 15; melamine cyanurate 5; pentaerythritol 3; PE wax 2

[0018] Preparation method: Knead aluminum hypophosphite, melamine cyanurate, pentaerythritol and PE wax at a temperature of 85°C for 1.5 hours according to the above ratio.

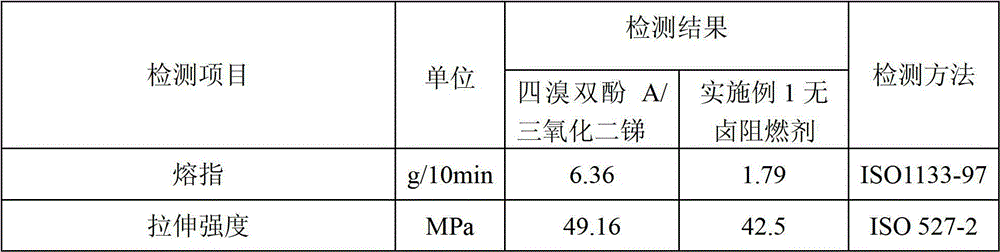

[0019] Bromine antimony flame retardant (parts by weight): tetrabromobisphenol A: 18, antimony trioxide: 6

[0020] The application of the obtained product in ABS is as follows (the addition amount of the halogen-free flame retardant is 25wt%, and the addition amount of the bromine-antimony flame retardant is 24wt%):

[0021] In ABS (0215A), after using a twin-screw extruder to prepare a modified material, use an injection molding machine to inject a standard sample, and test its performance. The results are shown in Table 2:

[0022] Table 2 The flame retardant application test results in ABS

[0023]

[0024]

[0025] The experimental data show that the flame retardant has no big d...

Embodiment 2

[0027] Proportion (parts by weight): aluminum hypophosphite: 17; melamine cyanurate: 5; pentaerythritol: 3

[0028] Preparation method: Knead aluminum hypophosphite, melamine cyanurate and pentaerythritol according to the above ratio at a temperature of 85°C for 1.5h.

[0029] Bromine antimony flame retardant (parts by weight): tetrabromobisphenol A: 18, antimony trioxide: 6

[0030] The application of the obtained product in ABS is as follows (the addition amount of the halogen-free flame retardant is 25wt%, and the addition amount of the bromine-antimony flame retardant is 24wt%):

[0031] In ABS (0215A), after using a twin-screw extruder to prepare a modified material, use an injection molding machine to inject a standard sample to test its performance. The results are shown in Table 3:

[0032] Table 3 The flame retardant application test results in ABS

[0033]

[0034]

[0035] The experimental data show that the tensile performance of the flame retardant in ABS...

Embodiment 3

[0037] Proportion (parts by weight): aluminum hypophosphite: 17; ammonium polyphosphate: 5; pentaerythritol: 3

[0038] Preparation method: Knead aluminum hypophosphite, ammonium polyphosphate and pentaerythritol according to the above ratio at 85°C for 1.5 hours.

[0039] Bromine antimony flame retardant (parts by weight): tetrabromobisphenol A: 18, antimony trioxide: 6

[0040] The application of the obtained product in ABS is as follows (the addition amount of the halogen-free flame retardant is 25wt%, and the addition amount of the bromine-antimony flame retardant is 24wt%):

[0041] In ABS (0215A), after using a twin-screw extruder to prepare a modified material, use an injection molding machine to inject a standard sample to test its performance. The results are shown in Table 4:

[0042] Table 4 Application test results of the flame retardant in ABS

[0043]

[0044]

[0045] Experimental data show that the flame retardant in ABS has slightly different tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com