Nano-Mg-Al hydrotalcite fire-retardant EVA foaming material and preparation method thereof

A technology of magnesium-aluminum hydrotalcite and foaming material, which is applied in the field of inorganic nano-scale magnesium-aluminum hydrotalcite composite flame-retardant EVA foaming material and its preparation field, can solve the problems such as the preparation method of the foaming material which is not mentioned, and achieve the improvement of vertical Combustion properties, improved mechanical and flame retardant properties, the effect of expanding the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

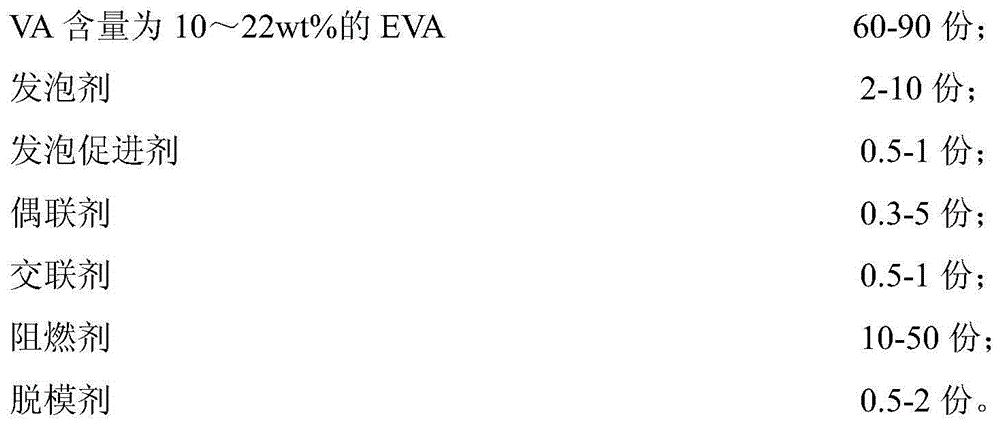

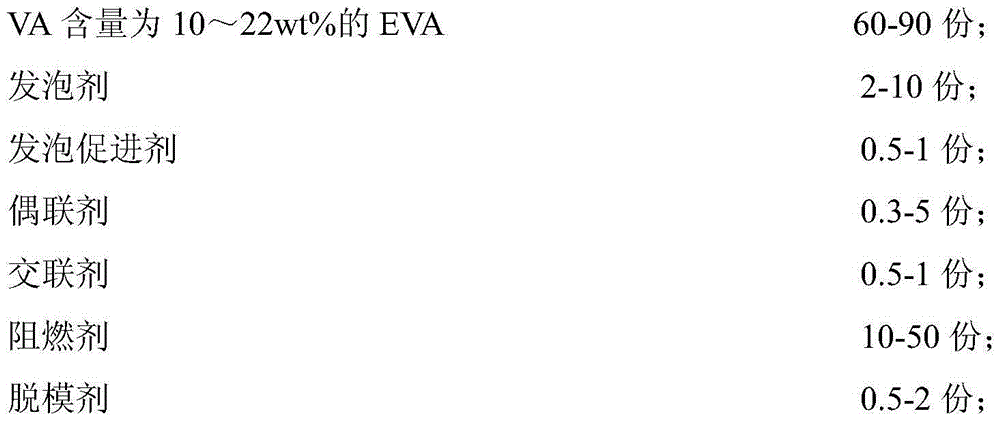

Method used

Image

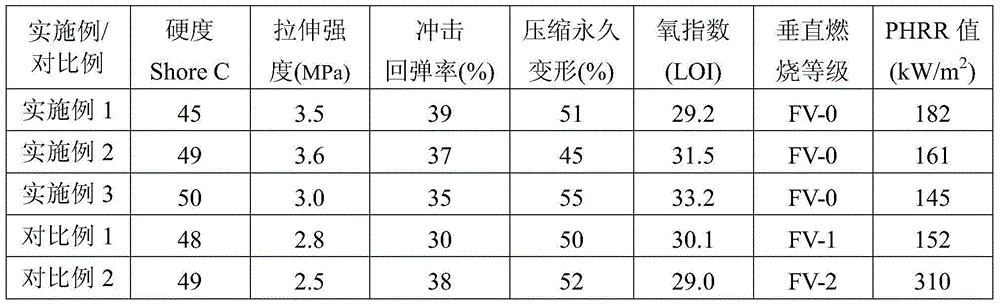

Examples

preparation example Construction

[0038] (2) Preparation of nanoscale magnesium aluminum hydrotalcite:

[0039] (1) Prepare solution A: Accurately weigh 81.33gMgSO according to the magnesium-aluminum molar ratio of 3 4 ·7H 2 O and 41.55gAl(NO 3 ) 3 9H 2 Put O in a beaker, add a small amount of water and stir to dissolve, transfer to a 250mL volumetric flask, shake to a constant volume, and set aside. (2) Configuration solution B (pH buffer): Weigh about 35.44g NaOH and 5.87g anhydrous Na 2 CO 3 Place in a beaker, add a small amount of water and stir to dissolve, transfer to a 250mL volumetric flask, shake to a constant volume, and set aside. (3) Take two constant-pressure dropping funnels and inject A and B solutions respectively for later use. (4) Add 200mL of distilled water to a 1L three-neck flask, control the water temperature at 60°C, stir vigorously, add solution A and solution B into the flask at the same time, and the addition is completed within 30 minutes. During the addition, the pH of the s...

Embodiment 1

[0041] Put 70 parts of ethylene vinyl acetate copolymer with a VA content of 14%, 0.5 part of stearic acid, 0.5 part of zinc stearate, 0.8 part of zinc oxide and 5 parts of talcum powder into a preheated internal mixer for mixing, After the temperature rises to 100°C, turn the material every 5°C; after rising to 115°C within 10 minutes, add 1 part of DCP, 6.5 parts of AC and 30 parts of nano-sized aluminum-magnesium hydrotalcite, and continue mixing for 5 minutes, every 2 ℃ Turn the material once, and the temperature rises to 120 ℃.

[0042] The roller mill is preheated to 90°C, the roller distance is 15mm, the mixed material is mixed twice in the form of a triangular bag, and then passed through the 1mm roller distance for three times, and then the sheet is released, and the sheet size is 110×30×0.1 cm, and stacked neatly.

[0043] Cut the pieces according to the shape of the mold, accurately weigh enough materials according to the modulus capacity, and fill the mold with ho...

Embodiment 2

[0045] Put 70 parts of ethylene vinyl acetate copolymer with a VA content of 18%, 0.5 part of stearic acid, 0.5 part of zinc stearate, 0.8 part of zinc oxide and 5 parts of talcum powder into a preheated internal mixer for mixing, After the temperature rises to 100°C, turn the material every 5°C; after rising to 115°C within 10 minutes, add 0.7 parts of DCP, 6.5 parts of AD300 and 30 parts of nano-scale aluminum-magnesium hydrotalcite, and continue mixing for 5 minutes, every Turn the material once every 2°C, and the temperature rises to 120°C.

[0046] The roller mill is preheated to 90°C, the roller distance is 15mm, the mixed material is mixed twice in the form of a triangular bag, and then passed through the 1mm roller distance for three times, and then the sheet is released, and the sheet size is 110×30×0.1 cm, and stacked neatly.

[0047] Cut the pieces according to the shape of the mold, accurately weigh enough materials according to the modulus capacity, and fill the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com