Steel-structure anti-corrosion coating and preparing mehtod thereof

A technology for anti-corrosion coatings and steel structures, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of limited application fields and single performance of anti-corrosion coatings, and achieve the effects of wide application, good solubility, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

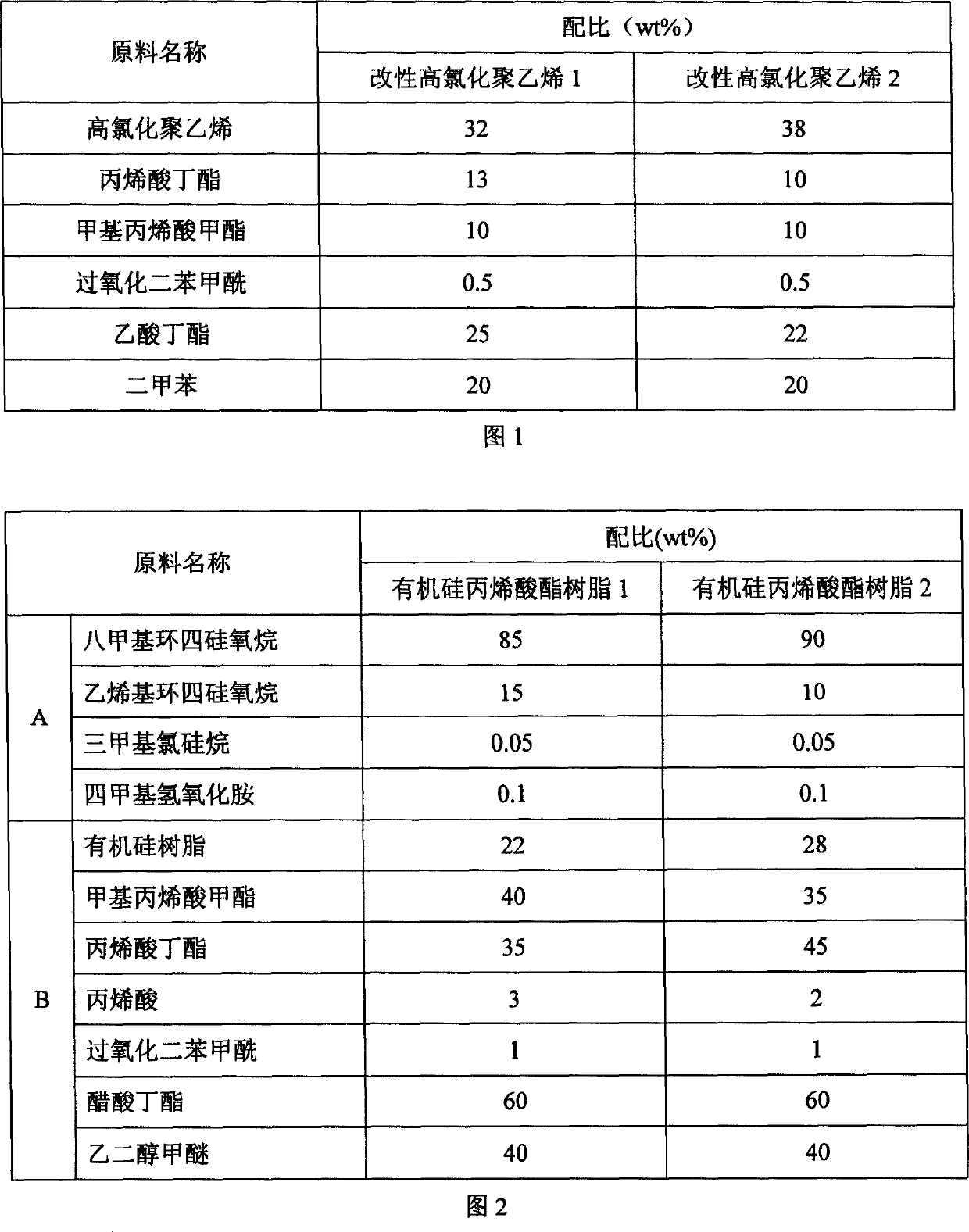

[0066] Refer to Figure 1 for the preparation formula of graft-modified high-chlorinated polyethylene. First, weigh according to the ratio of modified high-chlorinated polyethylene 1 in Figure 1. Then the reaction vessel was airtight and then evacuated and nitrogen flowed for 5 minutes respectively, and the operation was repeated three times to fully remove the air in the vessel. Add the estimated amount of the above ingredients. Under the protection of nitrogen, the mixture was stirred and heated to 110° C. for 4 hours to obtain a viscous liquid. Cool to about 100°C, vacuumize to remove unreacted monomers, and obtain modified high-chlorinated polyethylene resin. The resulting product had an initial melting temperature of 124°C and a graft weight gain of 16%.

Embodiment 2

[0068] Modified high-chlorinated polyethylene 2 was prepared according to the formula in Fig. 1, and the temperature was raised to 130° C., and reacted for 2 hours, and the rest of the preparation method was the same as that of Example 1. The initial melting temperature of the obtained product was 135° C., and the graft weight gain was 22%.

Embodiment 3

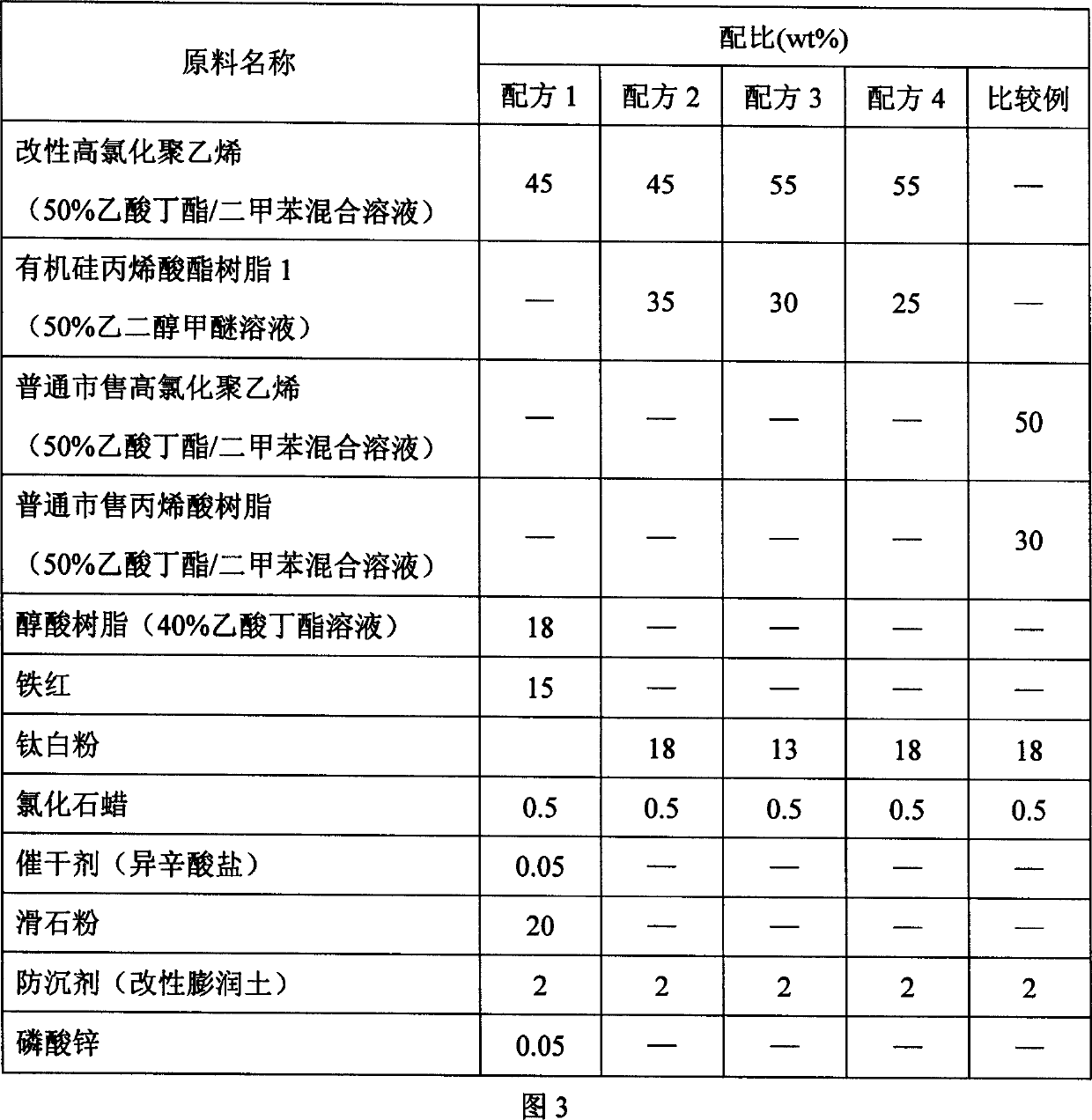

[0070] Refer to Figure 2 for the preparation formula of silicone acrylate resin. First, prepare according to the formula of silicone acrylate resin 1 in Fig. 2 . After sealing the reaction vessel, vacuumize and blow nitrogen for 5 minutes each, and repeat the operation three times to fully remove the air in the vessel. Add the estimated amount of octamethylcyclotetrasiloxane, vinylcyclotetrasiloxane, trimethylchlorosilane and tetramethylammonium hydroxide, and then evacuate until there are no escaped bubbles in the liquid. The temperature was raised to 150° C. for 4 hours to obtain a viscous liquid. Cool to about 100°C, vacuumize to remove unreacted monomers to obtain silicone resin.

[0071] Mix butyl acrylate, methyl methacrylate, acrylic acid and dibenzoyl peroxide in proportion and set aside. In a reaction vessel equipped with a stirrer, a condenser, a thermometer and a head tank, add the above-mentioned silicone resin, 30% butyl acetate and 20% ethylene glycol methyl e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com