Environment-friendly wall fireproof heat-preserving board and preparation method thereof

A fire-proof insulation board and an environment-friendly technology, which is applied in the field of fire-proof insulation of building walls, can solve the problem of straws not being effectively used, and achieve the effects of high flexural strength, easy availability of materials and small thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

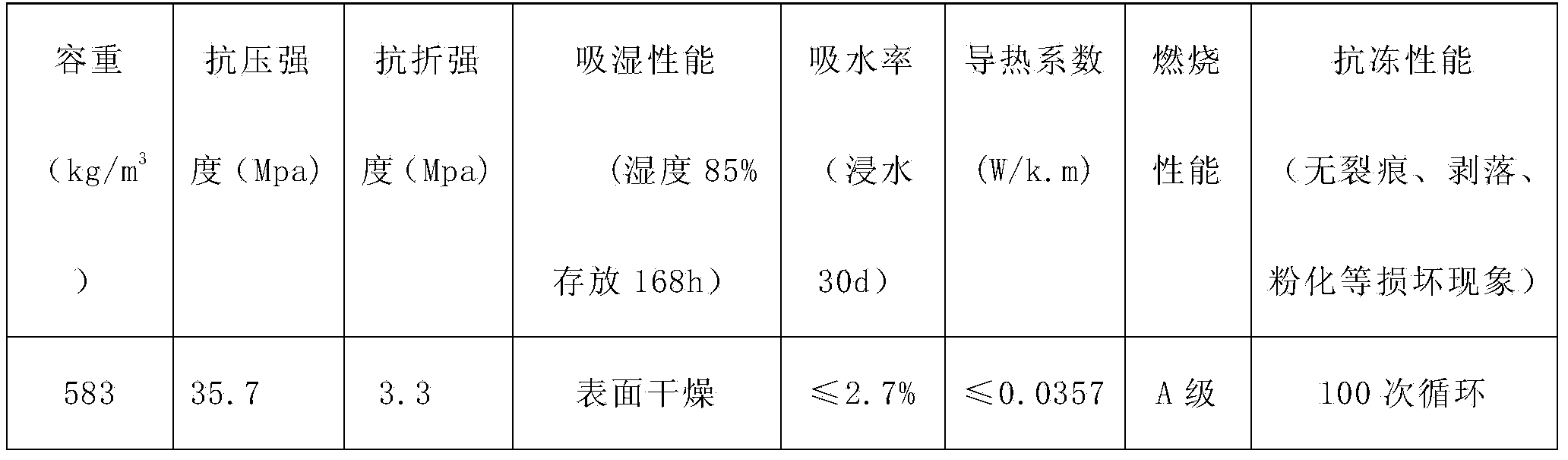

[0008] Example 1. Take 26kg of straw powder with a fiber length of 0.5mm, 0.5kg of amidinourea phosphate, 0.35kg of boric acid, 25kg of magnesium oxide, 17kg of fly ash, 9kg of perlite powder and 0.2kg of wood calcium, and then add 9kg of magnesium chloride, styrene-acrylic acid 0.2kg of emulsion and 13.1kg of tap water were stirred at 20°C for 4 minutes until uniform, then placed in a steel formwork, and rolled, cured, and demoulded to obtain a wall fireproof insulation board. After testing, its technical indicators are shown in Table 1.

[0009] Table 1

[0010]

Embodiment 2

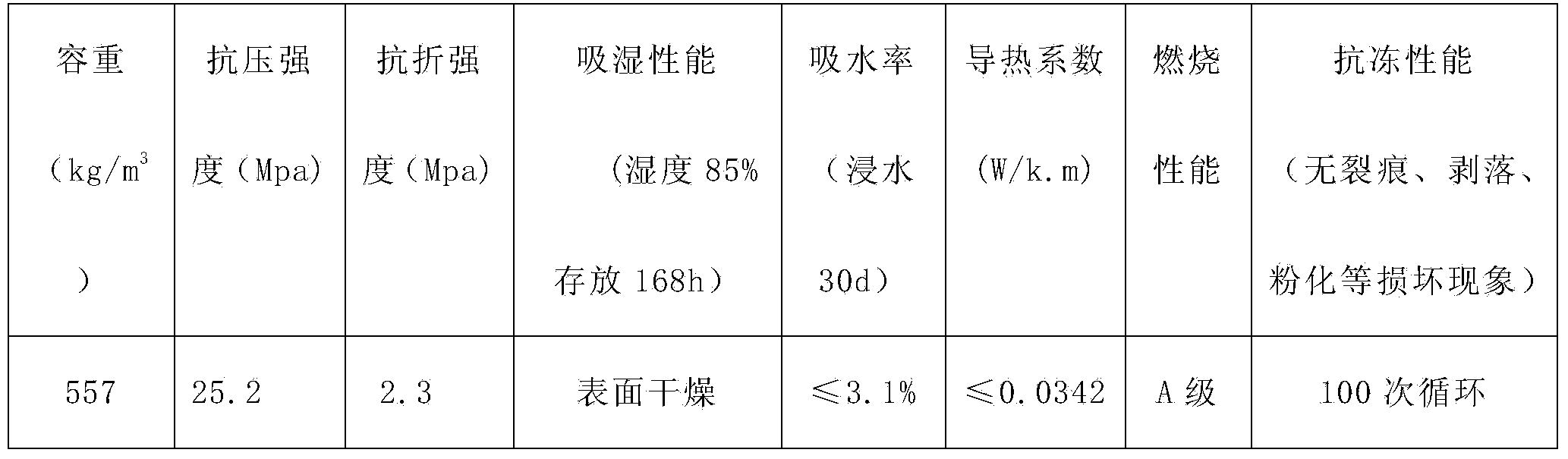

[0011] Example 2. Take 45kg of straw powder with a fiber length of 0.7mm, 0.9kg of amidinourea phosphate, 0.5kg of boric acid, 15kg of magnesium oxide, 10kg of fly ash, 14kg of perlite powder and 0.1kg of wood calcium, and then add 5.1kg of magnesium chloride, benzene 0.1kg of acrylic emulsion and 9.3kg of tap water were stirred at 25°C for 3.5 minutes until uniform, then placed in a plastic formwork, rolled, cured, and demoulded to obtain a wall fireproof insulation board. After testing, its technical indicators are shown in Table 2.

[0012] Table 2

[0013]

Embodiment 3

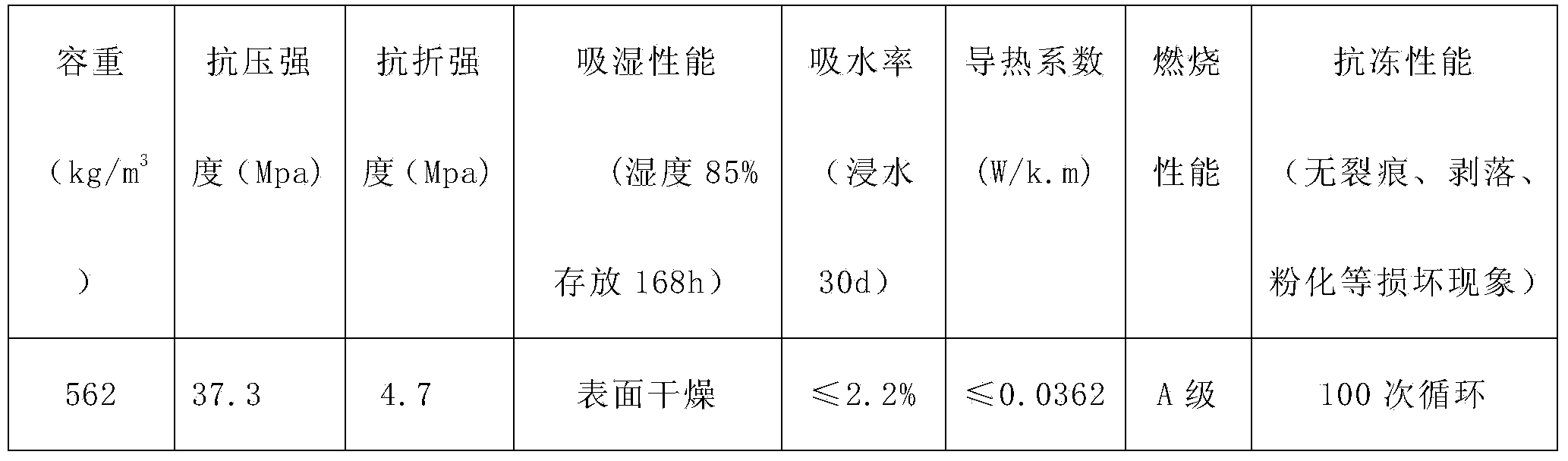

[0014] Example 3. Take 30kg of straw powder with a fiber length of 0.85mm, 0.5kg of amidinourea phosphate, 0.25kg of boric acid, 35kg of magnesium oxide, 2.9kg of diatomaceous earth powder, 1kg of perlite powder and 0.15kg of wood calcium, and then add 11.5kg of magnesium chloride , 0.1kg of styrene-acrylic emulsion and 10kg of tap water, stirred at 25°C for 3.5 minutes until uniform, placed in a plastic formwork, rolled, cured, and demoulded, to obtain a wall fireproof insulation board. After testing, its technical indicators are shown in Table 3.

[0015] table 3

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com