Layer-stranding fire-resisting, corrosive-proof and gopher protected communication outdoor cable

An outdoor optical cable, layer-twisted technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of short life of water blocking, need to be extremely careful, anti-corrosion, anti-rat and insect chewing can not play a role in inhibiting, so as to ensure long-term Safe use, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

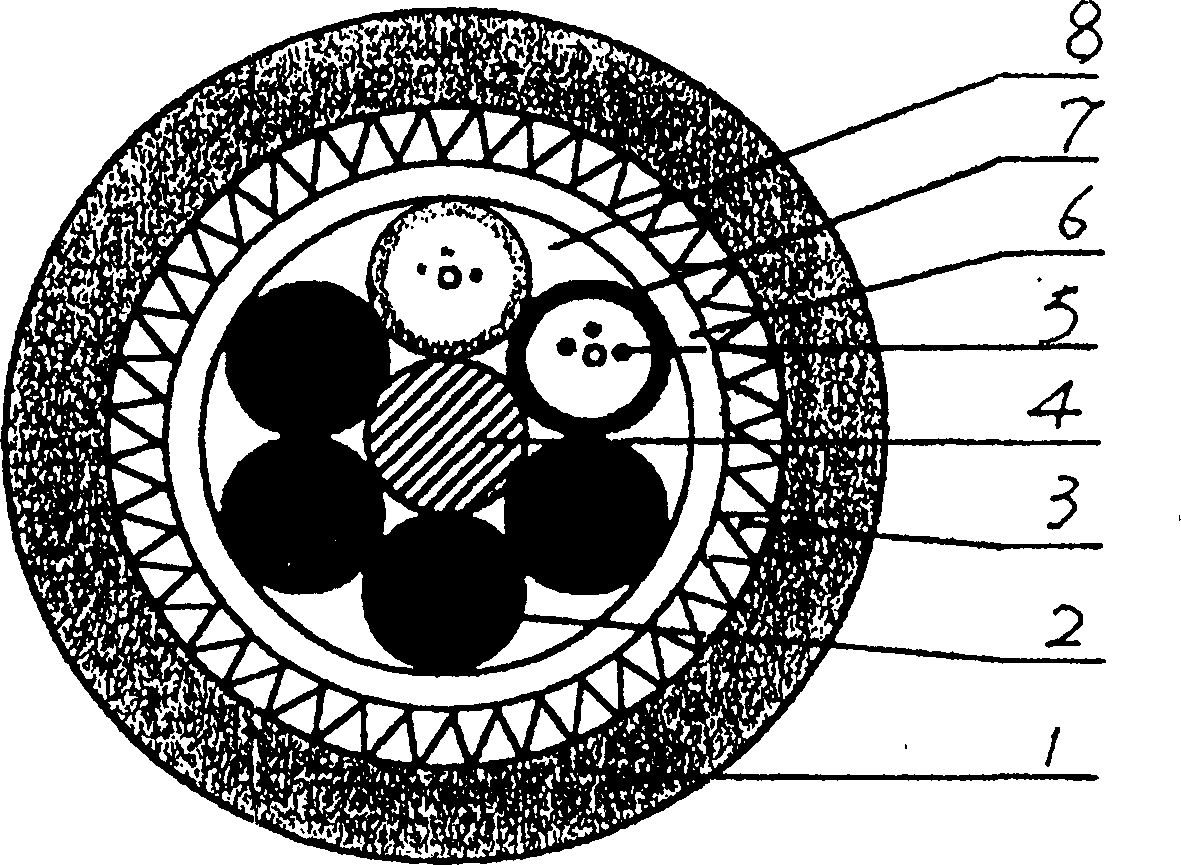

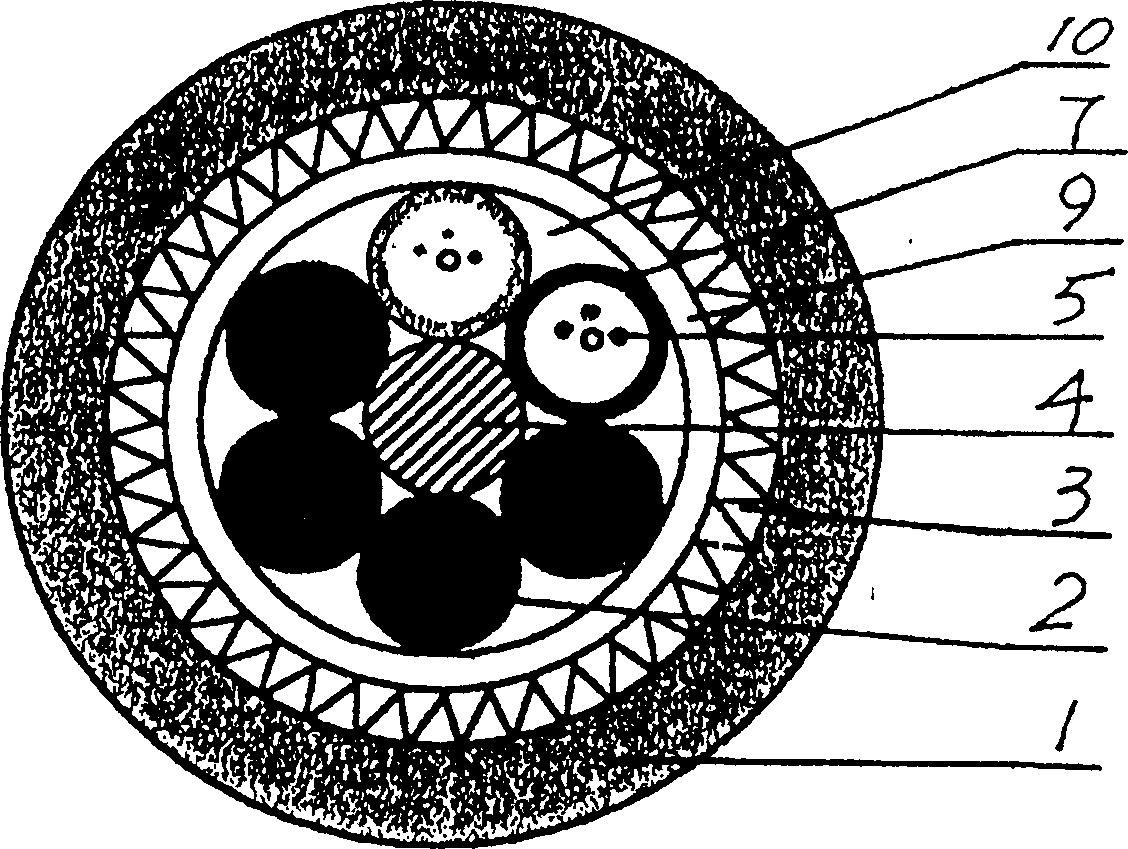

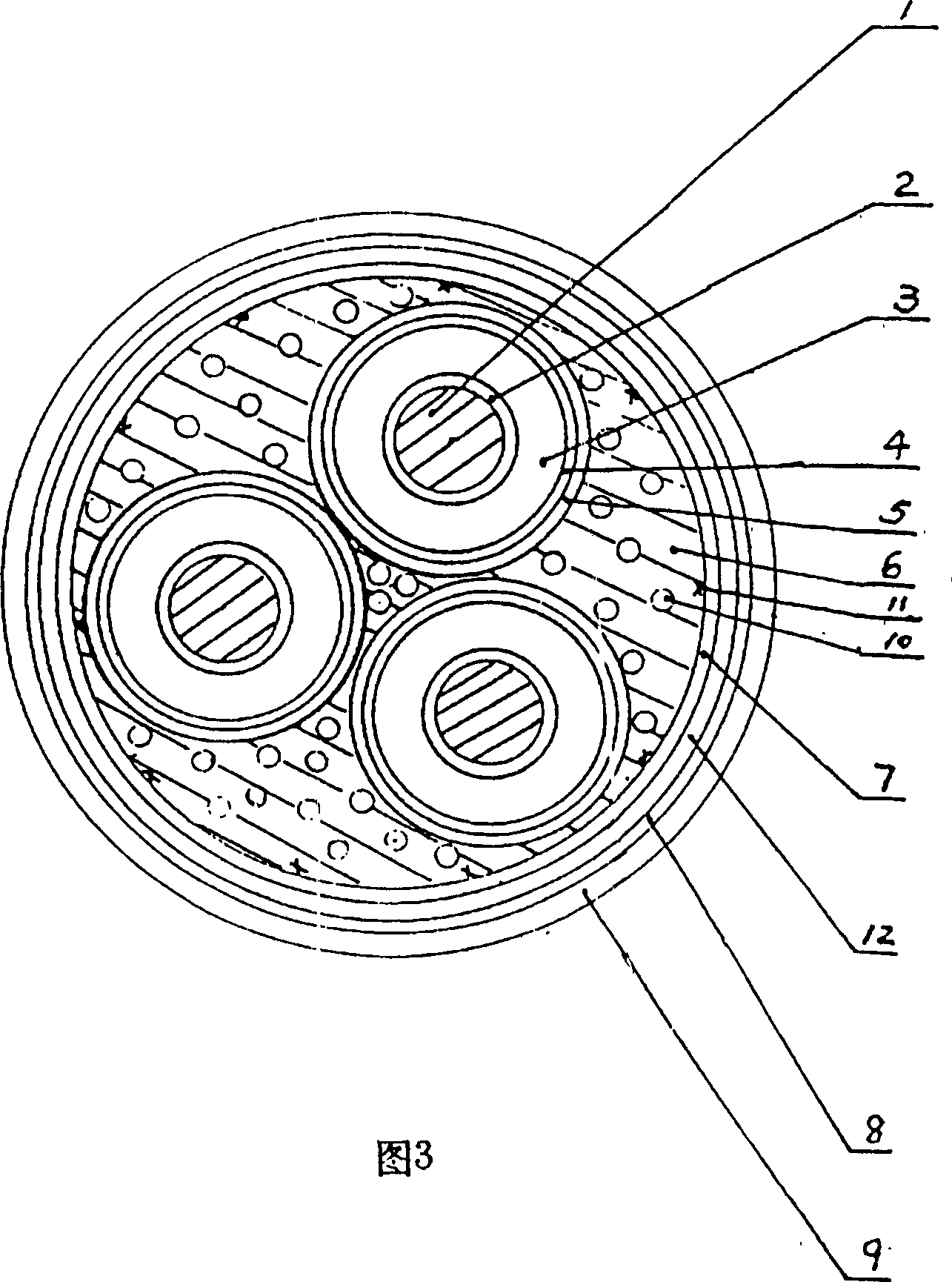

[0025] Take several sleeves 3 with a diameter of 1.9mm, and place one or more optical fibers 1 in each sleeve 3 as needed. Fill the cavities of each sleeve 3 with a filling material 2 and select the filling material 2 to have enough Viscosity in order to resist the shearing force exerted by the weight of the optical fiber 1 in the sleeve 3, and at the same time, allow the optical fiber 1 to move in the tube during the process of winding, laying and handling the optical cable, thereby preventing damage and traces of the optical fiber 1 Bending loss, so this filling material 2 adopts the filling compound for communication optical cable called YD / T839.1-2000 issued by the Ministry of Posts and Telecommunications of China. A number of sleeves 3 and a central reinforcement 4 are twisted left and right, also known as SZ stranding, and filled with filler 5 in the gap. The filler 5 is a filler compound glue for communication optical cables, thereby forming a layer stranding式线芯6。 Type cabl...

Embodiment 2

[0027] Only the diameter of the sleeve 3, the thickness of the adhesive layer 11 and the thickness of the flame-retardant layer 12 are changed to 2.1 mm, 0.7 mm, and 1.5 mm, respectively, and the rest are the same as in Embodiment 1.

Embodiment 3

[0029] Only the diameter of the sleeve 3, the thickness of the adhesive layer 11 and the thickness of the flame-retardant layer 12 are changed to 2.4 mm, 0.8 mm and 1.6 mm, respectively, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com