Glass fiber reinforced flame retardant polybutylene terephthalate resin composition with laser engraving function and preparation method thereof

A polybutylene terephthalate and resin composition technology is applied in the field of resin composition preparation and can solve the problems of uneven mixing of materials, poor temperature resistance, poor laser engraving effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

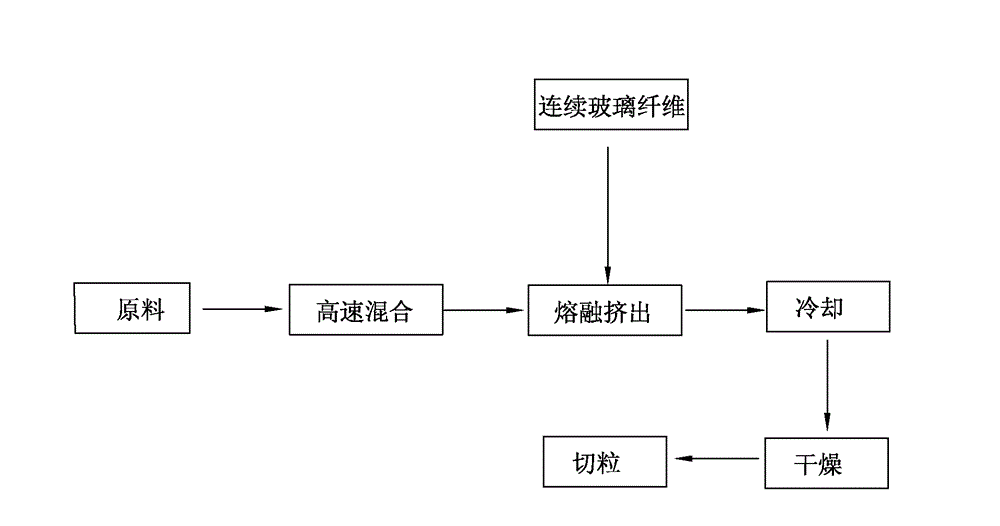

Image

Examples

Embodiment 1

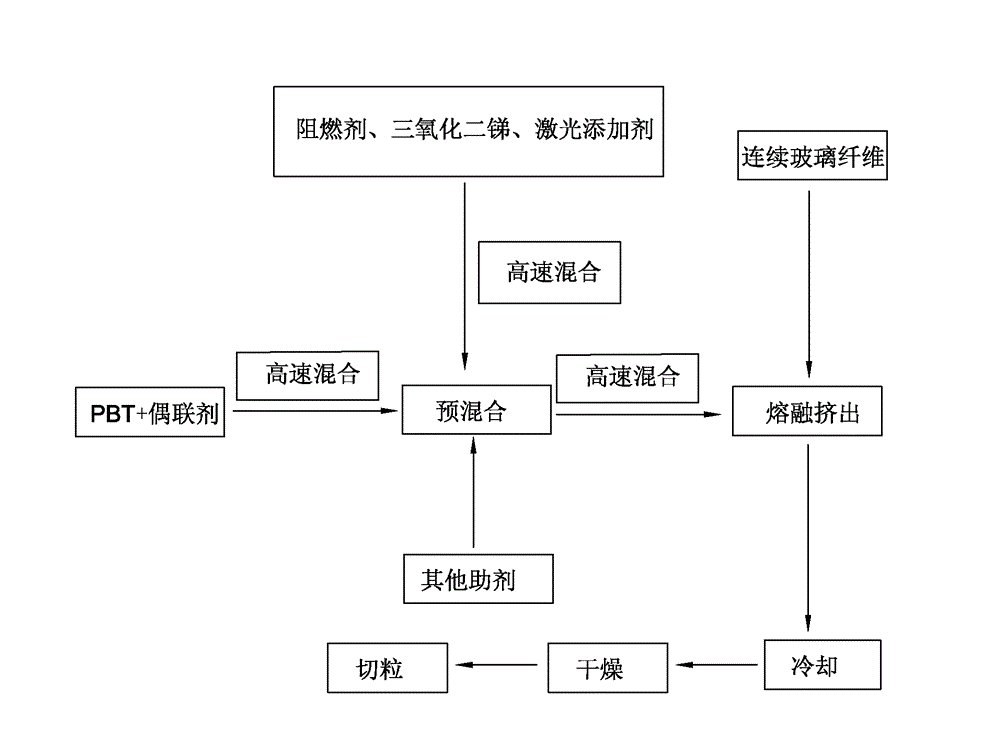

[0075] In parts by weight, weigh 73.2 parts of polybutylene terephthalate, 15 parts of brominated epoxy resin, 5 parts of antimony trioxide, and 5 parts of ethylene-butyl acrylate-glycidyl methacrylate copolymer , 1.0 parts of laser additive with brand WL515, 0.25 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester as the main antioxidant, and three [ 0.25 parts of 2.4-di-tert-butylphenyl] phosphite, 0.3 parts of pentaerythritol stearate; figure 2 Preparation flow chart First mix brominated epoxy resin, antimony trioxide and laser additives in a high-speed mixer, then add polybutylene terephthalate, ethylene-butyl acrylate-glycidyl methacrylate Copolymer, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol, tris[2.4-di-tert-butylphenyl]phosphite and pentaerythritol stearate Mix evenly in a high-speed mixer, then produce in a twin-screw extruder. Then cool, dry and cut into pieces.

[0076] Processing conditions: T...

Embodiment 2

[0078] In parts by weight, weigh 67.7 parts of polybutylene terephthalate, 12 parts of SR245 bromotriazine, 4 parts of antimony trioxide, and 4 parts of ethylene-butyl acrylate-glycidyl methacrylate copolymer , 0.8 parts of laser additives with brand BW550, 0.3 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, main antioxidant tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionate] 0.2 part of pentaerythritol ester, auxiliary antioxidant is 0.2 part of tris[2.4-di-tert-butylphenyl] phosphite, 0.3 part of pentaerythritol stearate, 0.5 part of carbon black, continuous 10 parts glass fiber; press at room temperature figure 2Preparation flow chart First mix SR245 bromotriazine, antimony trioxide and laser additives in a high-speed mixer, then add polybutylene terephthalate, ethylene-butyl acrylate-glycidyl methacrylate Copolymer, γ-(2,3-glycidoxy)propyltrimethoxysilane, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tri [2.4-Di-tert-but...

Embodiment 3

[0081] In parts by weight, weigh 60.85 parts of polybutylene terephthalate, 11 parts of brominated epoxy resin, 3.5 parts of antimony trioxide, and 3 parts of ethylene-butyl acrylate-glycidyl methacrylate copolymer , 0.6 parts by weight of laser additive with brand WL515, 0.3 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, main antioxidant tetrakis[β-(3,5-di-tert-butyl -4-hydroxyphenyl) propionate] 0.2 parts of pentaerythritol ester, auxiliary antioxidant is 0.2 parts of three [2.4-di-tert-butylphenyl] phosphite, 0.35 parts of montan wax, 20 parts of continuous glass fibers; press at room temperature figure 2 Preparation flow chart First mix brominated epoxy resin, antimony trioxide and laser additives in a high-speed mixer, then add polybutylene terephthalate, ethylene-butyl acrylate-glycidyl methacrylate Copolymer, γ-(2,3-glycidoxy)propyltrimethoxysilane, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tri [2.4-Di-tert-butylphenyl] p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com