Halogen-free flame retardant dynamically vulcanized EPDM/PP thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and dynamic vulcanization technology, applied in the field of composite materials, can solve the problems of reducing the mechanical properties and aging properties of materials, unsatisfactory flame retardancy and compression properties, easy water absorption and precipitation, etc., to achieve excellent comprehensive performance and low production cost. Low, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the above-mentioned halogen-free flame-retardant dynamic vulcanization EPDM / PP thermoplastic elastomer comprises the following steps:

[0056] 1) Add the composite halogen-free flame retardant into the high mixer, mix evenly, then add the silane coupling agent, mix evenly, and obtain the premix I;

[0057] 2) Add EPDM rubber, polypropylene, premix I and lubricant into the high mixer, mix evenly, then transfer the material to a co-rotating parallel twin-screw machine, plasticize, extrude and granulate to obtain premix Material II;

[0058]3) Add the premix II, cross-linking agent, auxiliary cross-linking agent and antioxidant into the high mixer, mix evenly, then transfer the material to the co-rotating parallel twin-screw machine, plasticize, extrude and granulate, and obtain no Halogen flame retardant dynamically vulcanized EPDM / PP thermoplastic elastomer.

[0059] Preferably, the extrusion granulation temperature in step 2) is 170-200°C.

...

Embodiment 1

[0063] A halogen-free flame-retardant dynamically vulcanized EPDM / PP thermoplastic elastomer, the raw material composition of which is shown in Table 1:

[0064] Table 1 The raw material composition of a halogen-free flame-retardant dynamically vulcanized EPDM / PP thermoplastic elastomer

[0065] raw material parts by mass EPDM 2470P 100 Polypropylene 1100NK 67 Bis-tert-butylperoxycumene (BIBP) 1 Triallyl isocyanurate (TAIC) 2 Epoxy Resin Modified Crystal Type Ⅱ Ammonium Polyphosphate 28 Polytriazine (HCFA) 14 Organic Nano Silica 2 Vinyltriethoxysilane 0.5 Ethylene bis fatty acid amide (EBS) 1 Antioxidant 1076 1

[0066] The preparation method of the above-mentioned halogen-free flame-retardant dynamic vulcanization EPDM / PP thermoplastic elastomer is as follows:

[0067] 1) Epoxy-modified ammonium polyphosphate, polytriazine and organic nano silicon dioxide are added to the high mixer, stirred for 10 min...

Embodiment 2

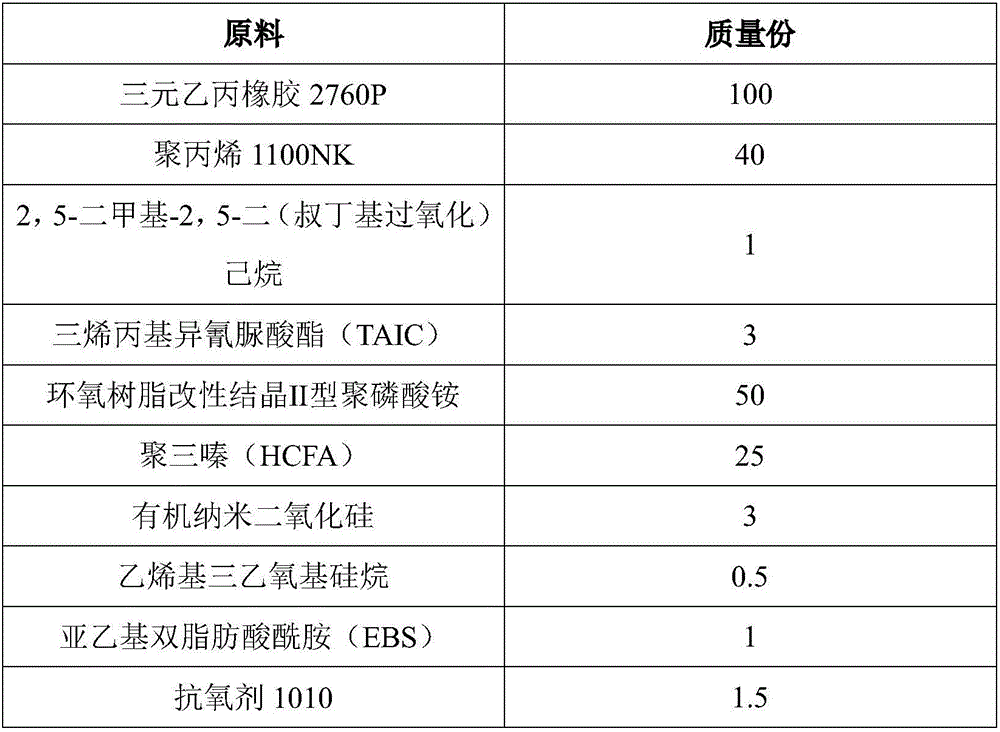

[0071] A halogen-free flame-retardant dynamically vulcanized EPDM / PP thermoplastic elastomer, the raw material composition of which is shown in Table 2:

[0072] Table 2 The raw material composition of a halogen-free flame-retardant dynamically vulcanized EPDM / PP thermoplastic elastomer

[0073]

[0074] The preparation method of the above-mentioned halogen-free flame-retardant dynamic vulcanization EPDM / PP thermoplastic elastomer is as follows:

[0075] 1) Epoxy-modified ammonium polyphosphate, polytriazine and organic nano-silica were added to the high mixer, stirred for 15 minutes, added vinyltriethoxysilane, stirred for 10 minutes, and obtained premix I;

[0076] 2) Add EPDM rubber 2760P, polypropylene 1100NK, premix I and ethylene bisfatty acid amide (EBS) into the high mixer, stir for 15 minutes, then transfer the materials to the parallel twin-screw machine in the same direction, and plasticize Chemical, extrude and granulate at 180-200°C to obtain premix II;

[00...

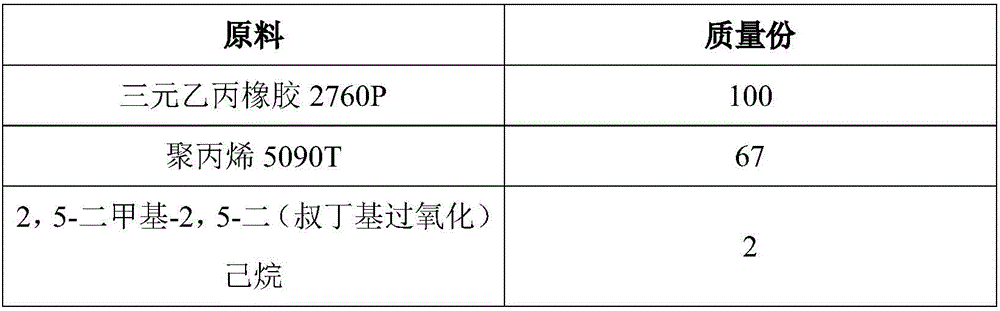

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com