Antistatic halogen-free flame-retardant ultra-high molecular weight polyvinyl composite

A technology of ultra-high molecular weight and composition, which is applied in the field of polymer modification processing and halogen-free flame retardants. It can solve the problems of endangering human and environmental safety, harmful gases, and large quantities, and achieves excellent flame retardancy and antistatic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be described in detail below in conjunction with specific examples, however, the examples are not limitations of the present invention.

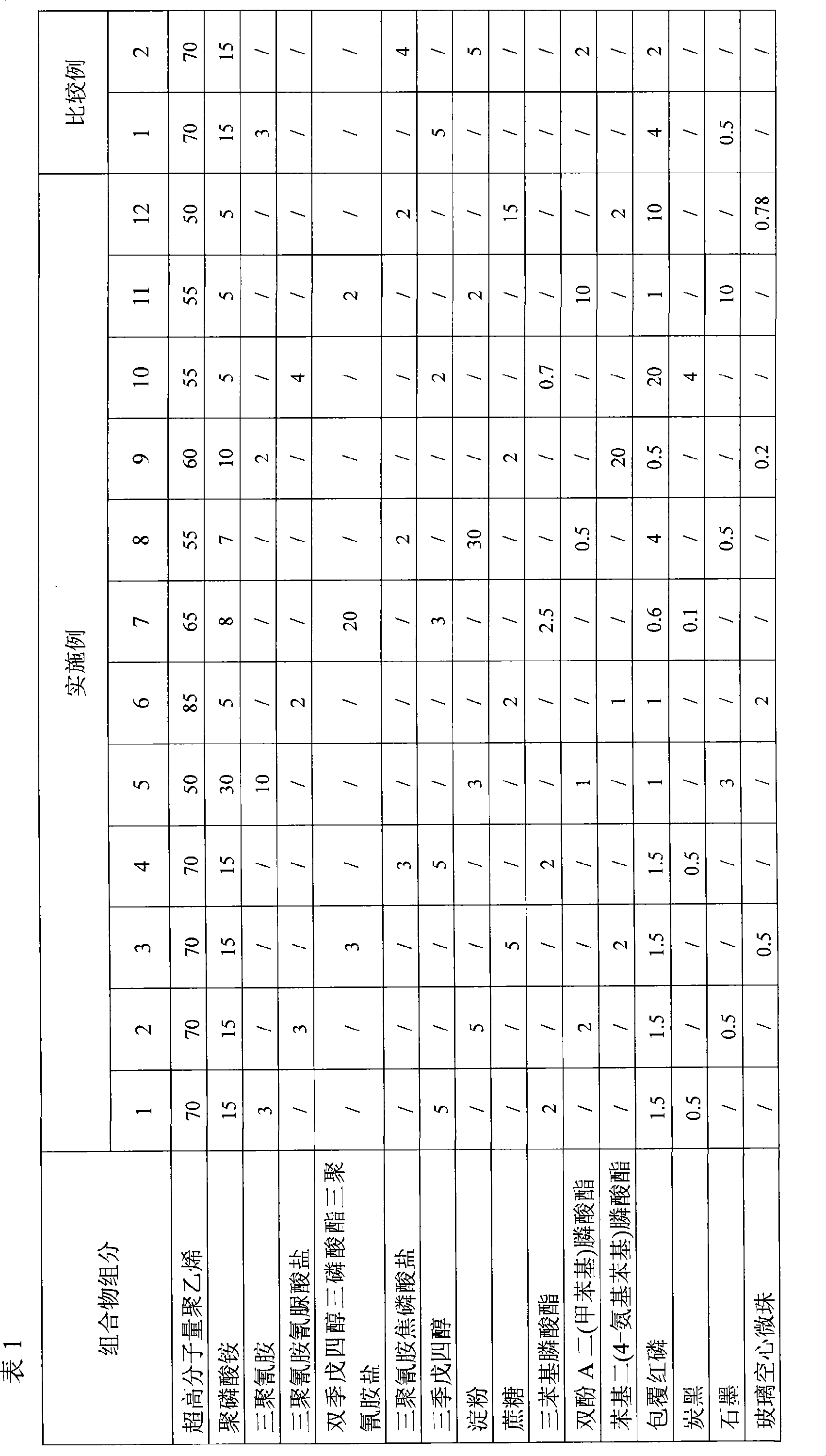

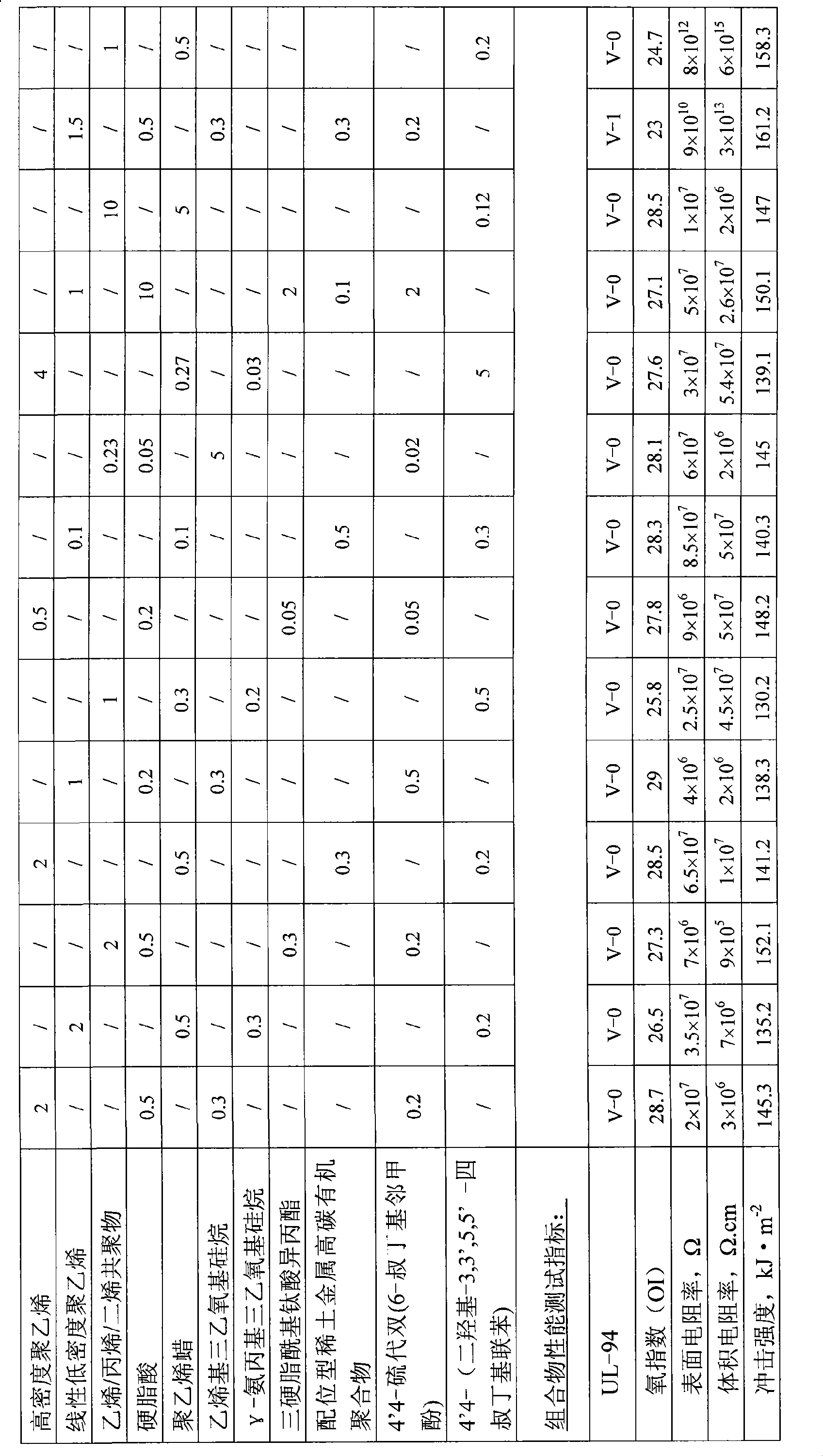

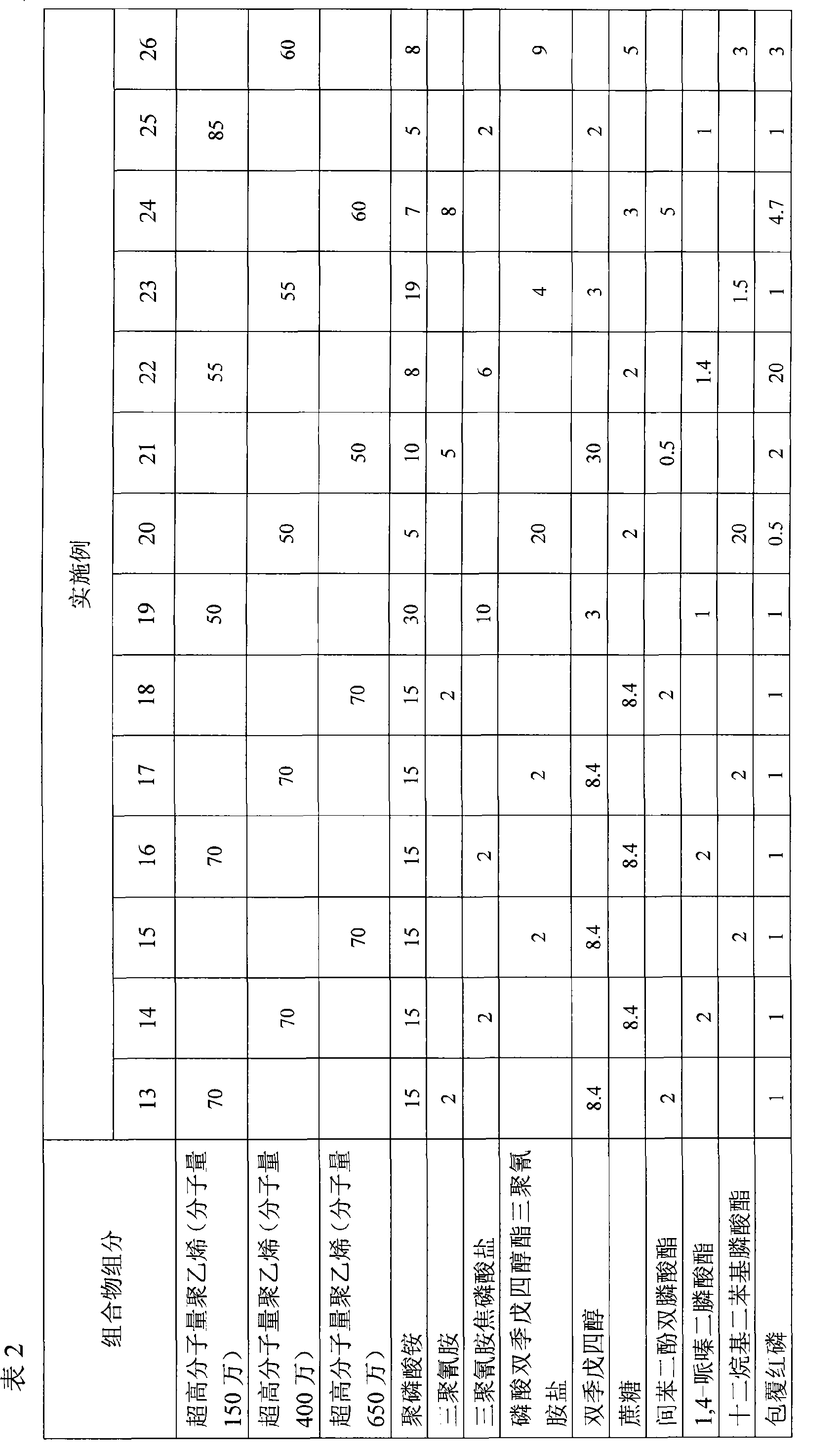

[0029] The compositions described in Examples 1 to 12 and Comparative Examples 1 and 2 are prepared by the following method, and the addition amount of each component is as shown in Table 1, and the addition amount values of each component listed in Table 1 are all parts by weight . The performance indicators of the prepared antistatic halogen-free flame-retardant ultra-high molecular weight polyethylene composition are also listed in Table 1.

[0030] Preparation of Antistatic Halogen Free Flame Retardant Ultra High Molecular Weight Polyethylene Composition :

[0031] Ammonium polyphosphate, melamine and its derivatives, polyols, and phosphonates are firstly mixed in proportion, then mixed evenly at high speed, and then a certain amount of ultra-high molecular weight polyethylene, coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com