A kind of PBT material with good epoxy resin adhesion and preparation method thereof

An epoxy resin, epoxy resin curing technology, applied in the field of PBT materials and their preparation, can solve the problems of gap, aging temperature is only 90 ℃, time is only 500 hours, etc., to achieve convenient operation, excellent anti-aging performance, excellent interface The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

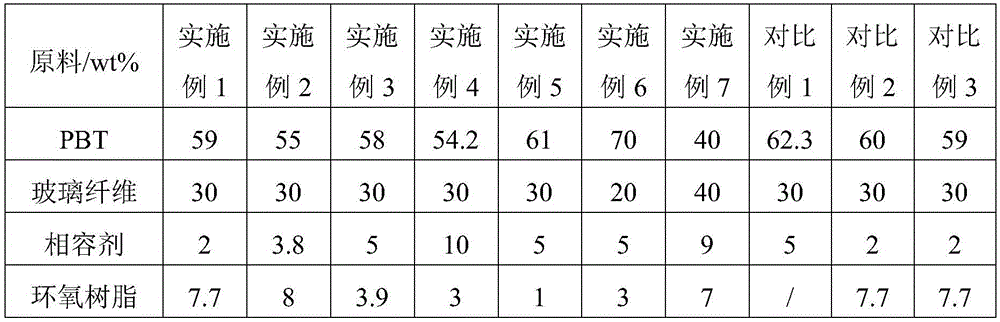

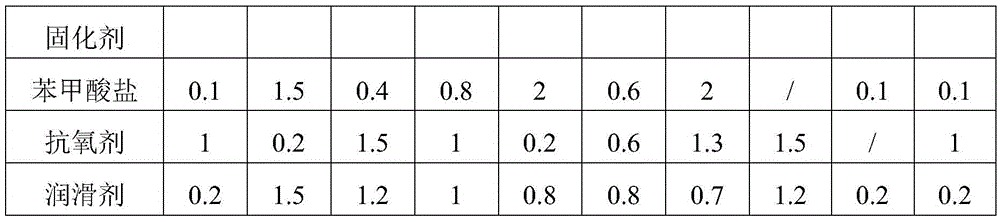

[0029] (1) prepare materials according to the components and parts by weight of Table 1;

[0030] (2) Put PBT, compatibilizer, epoxy resin curing agent, benzoate, antioxidant, lubricant into the high-speed mixer, and mix for 3 minutes;

[0031] (3) Extrude the above-mentioned mixed material through a twin-screw extruder and granulate it. Glass fiber is added from the middle and downstream of the twin-screw extruder. The speed of the extruder is 400 rpm and the temperature is 235°C.

[0032] The PBT used is PBTBM434 produced by Yizheng Chemical Fiber, and its characteristic viscosity is 1.2dl / g; the compatibilizer used is AX8900 produced by Arkema, France; the epoxy resin curing agent used is an aromatic amine curing agent, manufactured by Shanghai The m-phenylenediamine (CAS: 108-45-2) produced by Anuofang Amine Chemicals Co., Ltd.; the benzoate used is sodium benzoate (CAS: 532-32-1) produced by Tianjin Dongda Chemical Co., Ltd.; the used The antioxidant is antioxidant 24-44...

Embodiment 2

[0034] (1) prepare materials according to the components and parts by weight of Table 1;

[0035] (2) Put PBT, compatibilizer, epoxy resin curing agent, benzoate, antioxidant, lubricant into the high-speed mixer, and mix for 5 minutes;

[0036] (3) Extrude and pelletize the above-mentioned mixed material through a twin-screw extruder, and add glass fiber from the middle and downstream of the twin-screw extruder, the extruder speed is 500 rpm, and the temperature is 245°C.

[0037] The PBT used is PBTBM434 produced by Yizheng Chemical Fiber, with an intrinsic viscosity of 1.2dl / g; the compatibilizer used is AX8900 produced by Arkema, France; the epoxy resin curing agent used is a polyamide curing agent manufactured by Jiangqiao Chemical The oligoamide 2140 produced by the factory has a viscosity of 250-400mPa.s / 75°C; the benzoate used is a mixture of potassium benzoate and sodium benzoate in a weight ratio of 2:1, and the sodium benzoate is produced by Tianjin Dongda Chemical I...

Embodiment 3

[0039] (1) prepare materials according to the components and parts by weight of Table 1;

[0040] (2) Put PBT, compatibilizer, epoxy resin curing agent, benzoate, antioxidant, lubricant into the high-speed mixer, and mix for 8 minutes;

[0041](3) Extrude and pelletize the above-mentioned mixed materials through a twin-screw extruder, and add glass fibers from the middle and downstream of the twin-screw extruder, the extruder speed is 180 rpm, and the temperature is 225°C.

[0042] The PBT used is PBTBM434 produced by Yizheng Chemical Fiber, with an intrinsic viscosity of 1.2dl / g; the compatibilizer used is AX8900 produced by Arkema, France; the epoxy resin curing agent used is polyamide curing agent and aromatic amine Curing agent is the mixture of 2:1.9 by weight, and described polyamide curing agent is produced by Jiangqiao Chemical Plant oligoamide 2140, and its viscosity is 250-400mPa.s / 75 ℃, and the aromatic amine curing agent used is made of m-phenylenediamine (CAS: 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com