Composition for anti-pollution flashover coating and anti-pollution flashover coating

An anti-fouling flashover coating and composition technology, applied in the direction of coating, etc., can solve the problems of water flow channels and large stagnation areas, atmospheric aging performance cannot be significantly improved, and flashover channels are formed, so as to improve the antifouling Water mobility, avoiding pollution flashover accidents, and strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

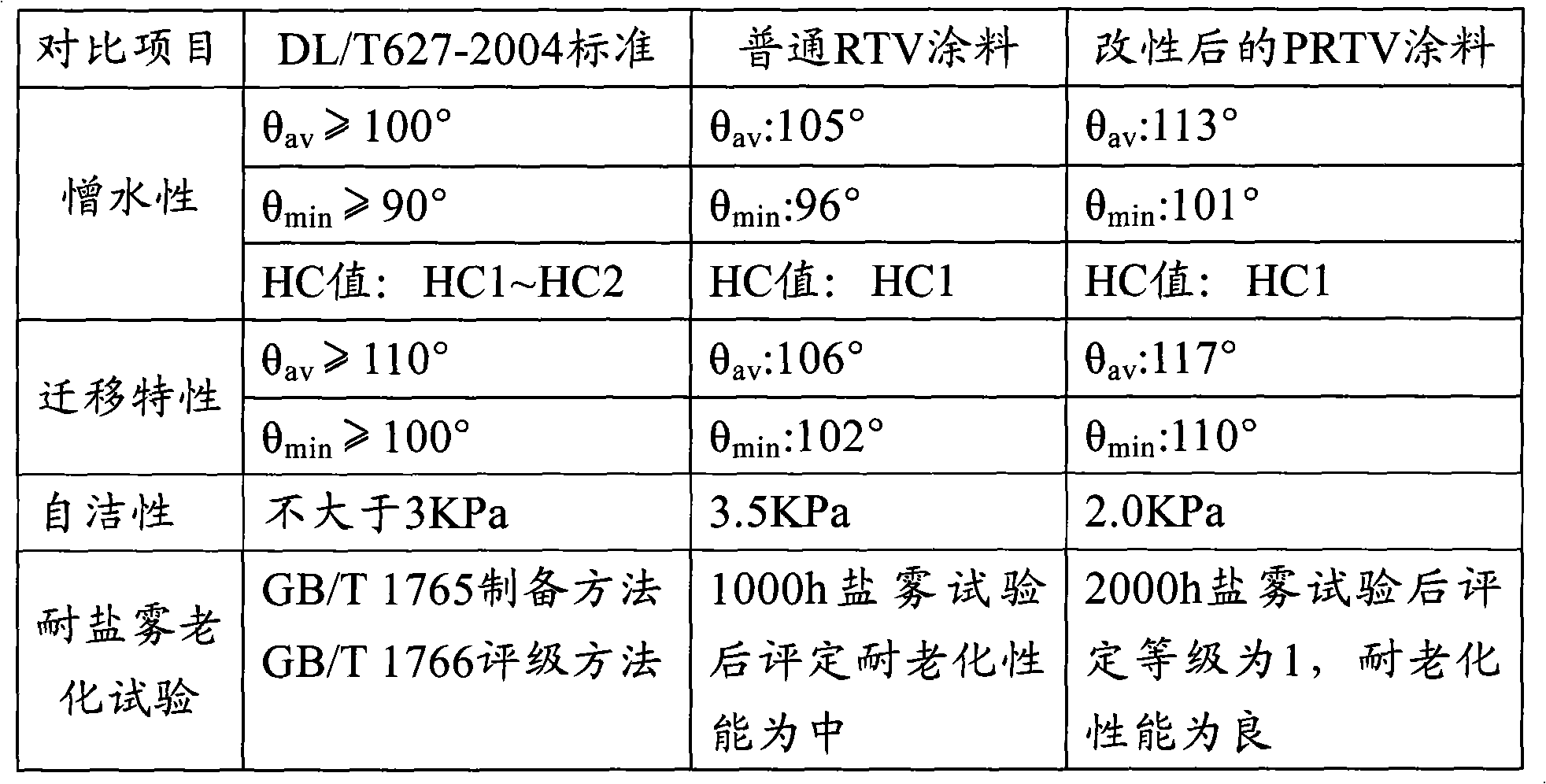

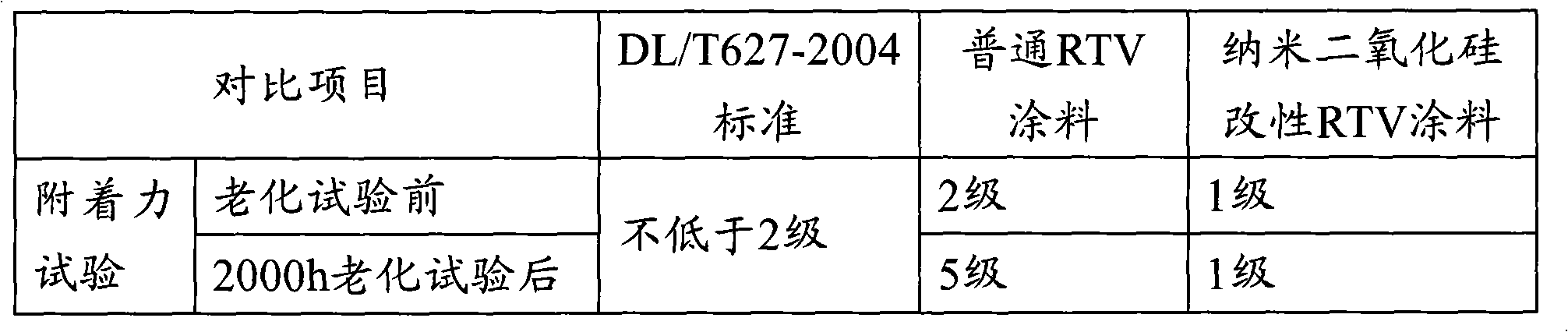

[0026] 1. Formula of antifouling flashover paint

[0027] Component

parts by weight

107 silicone rubber

28.5

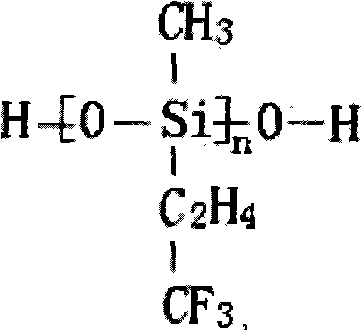

Hydroxyl-terminated fluoropolysiloxane

10.0

Hydrophobic nano fumed silica

7.7

4.05

Compound Al-Mg Flame Retardant

9.6

3.1

iron red pigment

0.4

0.01

Methyltributanoximinosilane

5.44

1.3

platinum catalyst

0.25

0.03

120# solvent

19.32

D30 dearomatization solvent

10.3

total

100

[0028] 2. Preparation process:

[0029] (1) Equipment: vacuum kneader, three-roll machine, planetary mixer, pressing machine.

[0030] (2) Process flow: put 107 silicone rubber (hydroxyl-terminated polysiloxane), hydroxy-terminated fluorine-containing polysiloxane, and dimethyl silicone oil into a vacuum knea...

Embodiment 2

[0035] 1. Formula of antifouling flashover paint

[0036] Component

[0037] 2. The preparation process is the same as in Example 1.

Embodiment 3

[0039] 1. Formula of antifouling flashover paint

[0040] Component

[0041] 2. The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com