Internal and external finned tube inside evaporating and condensing dual-use ladder-shaped grid

An evaporative condensation and grid fin technology is applied in the field of finned tubes inside and outside the stepped grid to achieve the effects of promoting disturbance, strengthening evaporation and condensation performance, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below.

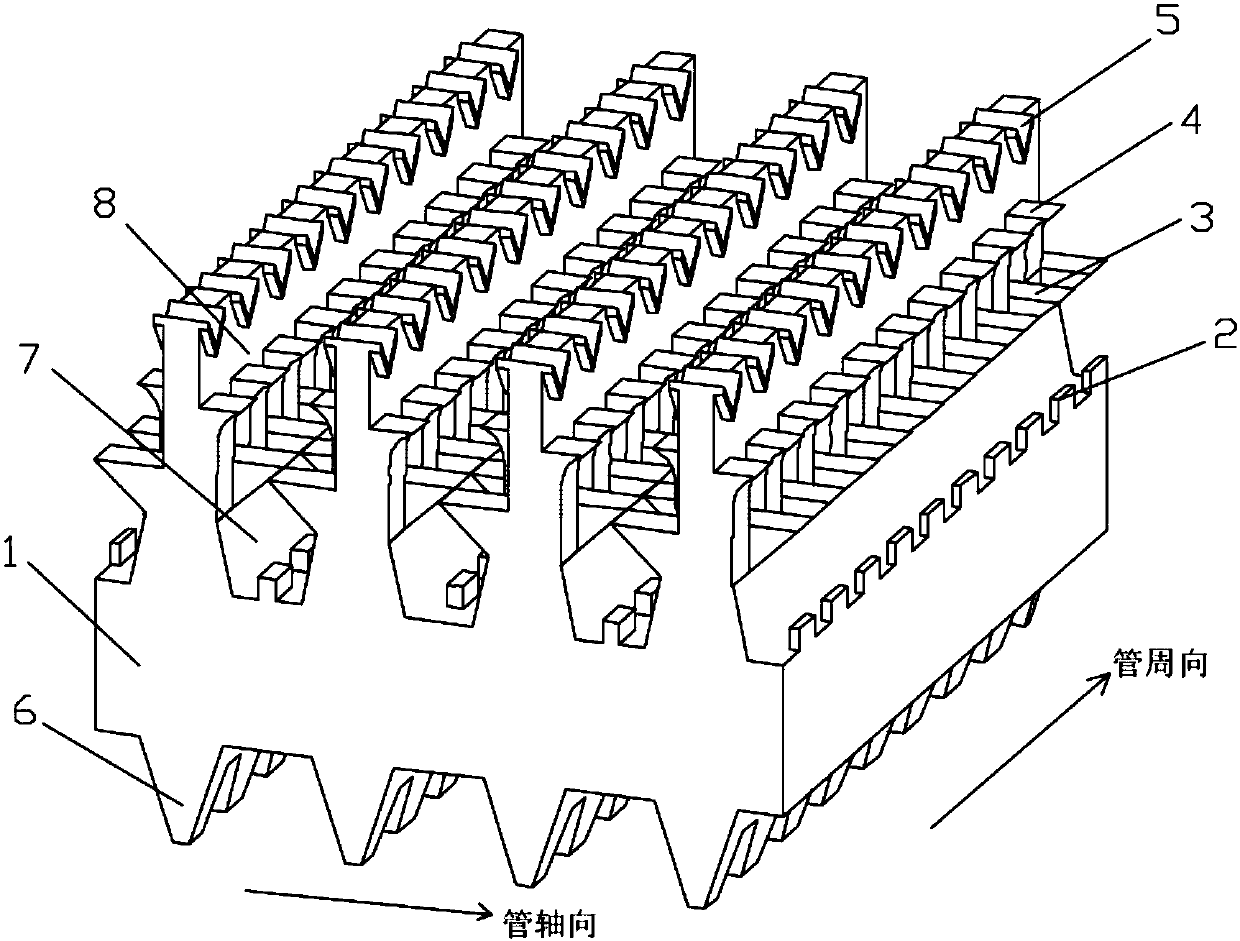

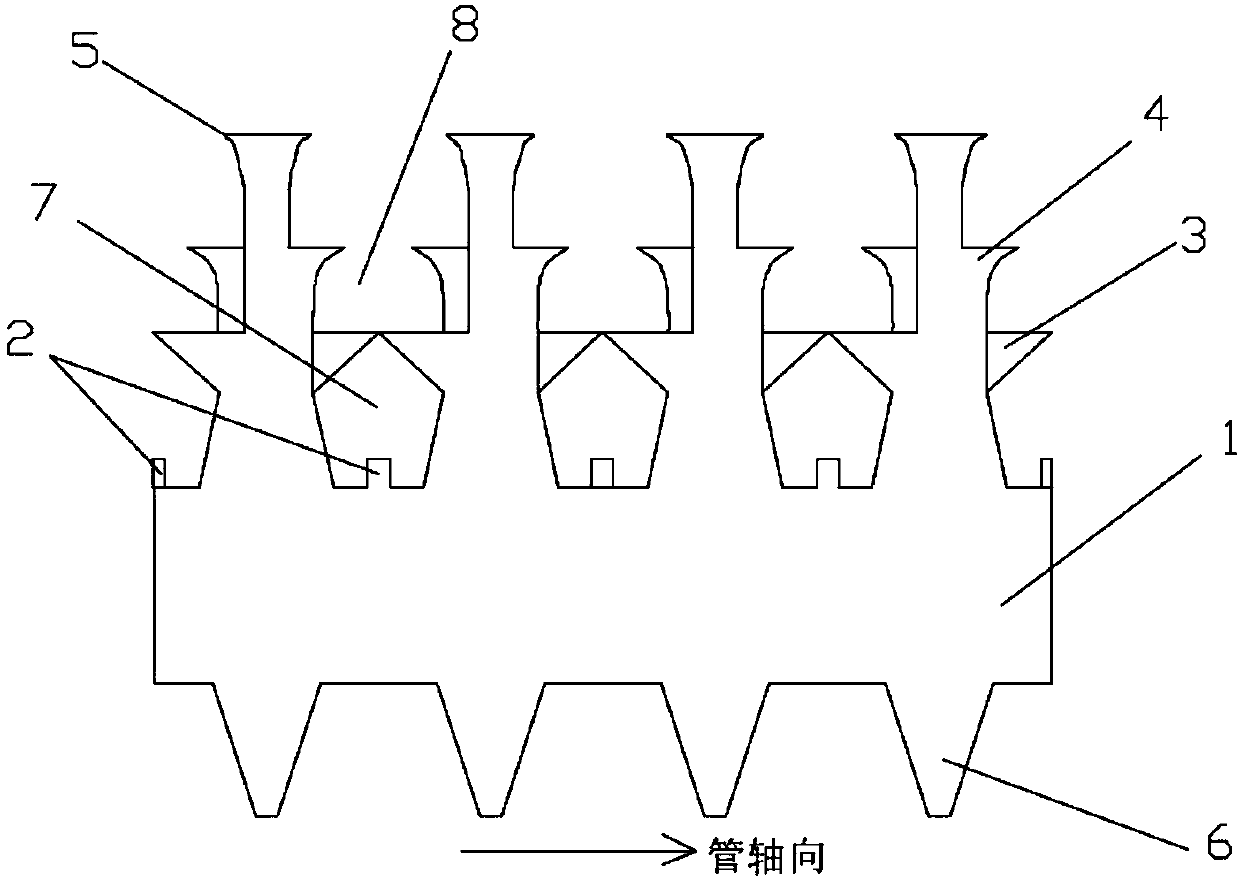

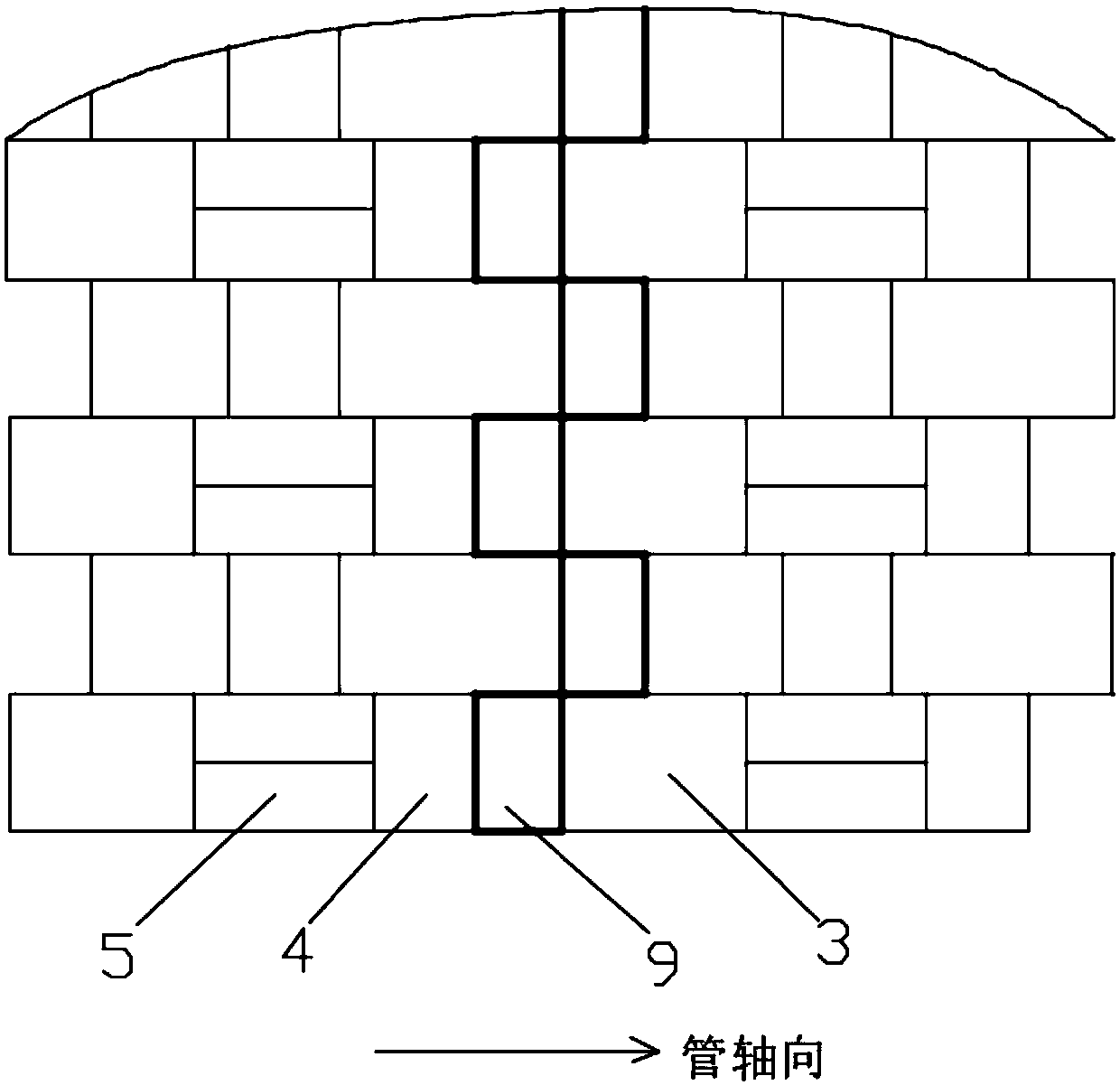

[0032] A stepped palace grid inner and outer fin tube for both evaporation and condensation, comprising a tube base, spiral sawtooth inner fins, spiral sawtooth outer fins, inter-slot convex teeth, palace grid fins, stepped fins, and triangular top teeth.

[0033] The spiral sawtooth inner fins are on the inner wall of the tube base, and the spiral sawtooth outer fins are on the outer wall of the tube base. In the axial direction, two adjacent spiral sawtooth outer fins form gaps, and the protruding teeth of the gaps are located on the outer wall of the tube base. And located in the groove, the triangular top teeth are located on the outer top of the spiral sawtooth outer fin; the palace grid fins are located on both sides of the spiral sawtooth outer fin, and the palace grid fins on both sides of the same spiral sawtooth outer fin are alternately distributed, so that On the adjacent sides of the adjacen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com