Baffle high-efficient heat exchanger

A heat exchanger, high-efficiency technology, applied in the direction of heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of complex scaling of heat exchangers, increased heat transfer resistance, increased pump power, etc., to achieve Large-scale heat exchange function, improved heat exchange efficiency, and full effect of baffle flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

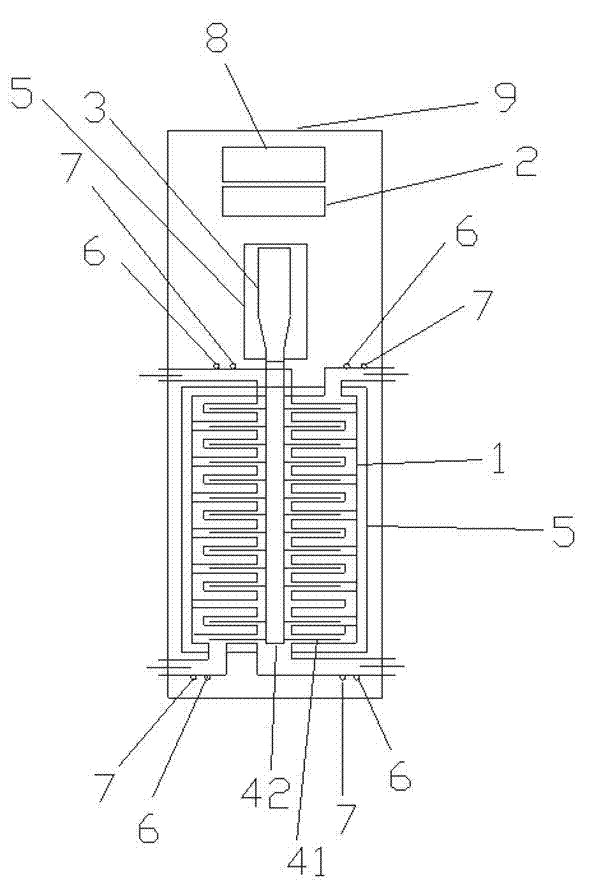

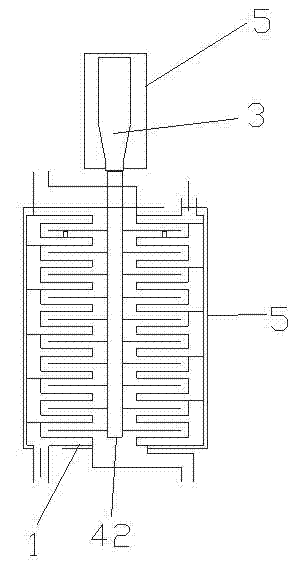

[0037] See figure 1 with figure 2 , The high-efficiency baffled heat exchanger provided by this embodiment includes:

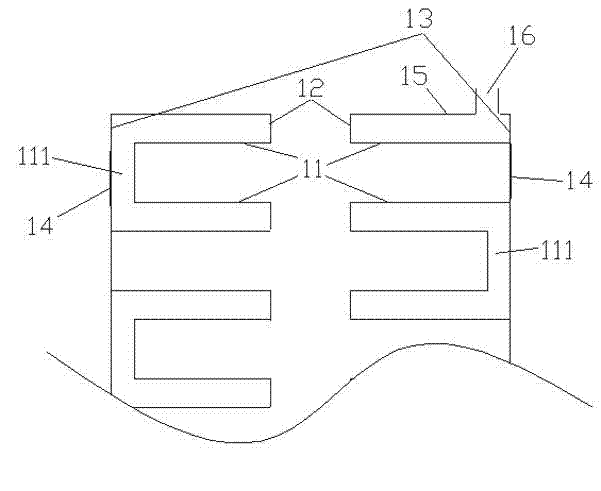

[0038] The corrugated baffled heat exchanger shell 1 is used to ensure the baffled flow of the heat exchange medium in the heat exchanger shell; see image 3 Specifically, the heat exchanger housing 1 provided here in this embodiment is a circular corrugated baffled heat exchanger housing, which is mainly composed of circular corrugated baffled heat exchange fins 11 and a circular isolation ring , The circular isolation ring is provided on the inner and outer sides of the circular corrugated baffle heat exchange sheet 11, which specifically includes a circular inner ring isolation ring 12, a circular outer ring isolation ring, the circular outer ring isolation ring further includes a circular The thin-shaped outer ring isolation ring 13 and the thick circular outer ring isolation ring 14, wherein the circular inner ring isolation ring 12 is arranged on the inner ...

Embodiment 2

[0045] This embodiment provides a baffled high-efficiency heat exchanger group, which is composed of the baffled high-efficiency heat exchanger in Embodiment 1, and the controller of the heat exchange efficiency real-time monitoring and control system is corresponding to each heat exchanger Multiple individually set controllers or one integrated large controller for controlling all heat exchangers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com