Tube-fin type heat exchange unit with high pressure resistance

a heat exchange unit and tube-fin technology, applied in the field of tube-fin heat exchange units with high pressure resistance, can solve the problems of low heat exchange efficiency, small heat exchange area, and large volume, and achieve high heat exchange efficiency, large heat transfer surface, and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011]The present invention will be described further referring to the accompanying drawings and the embodiments.

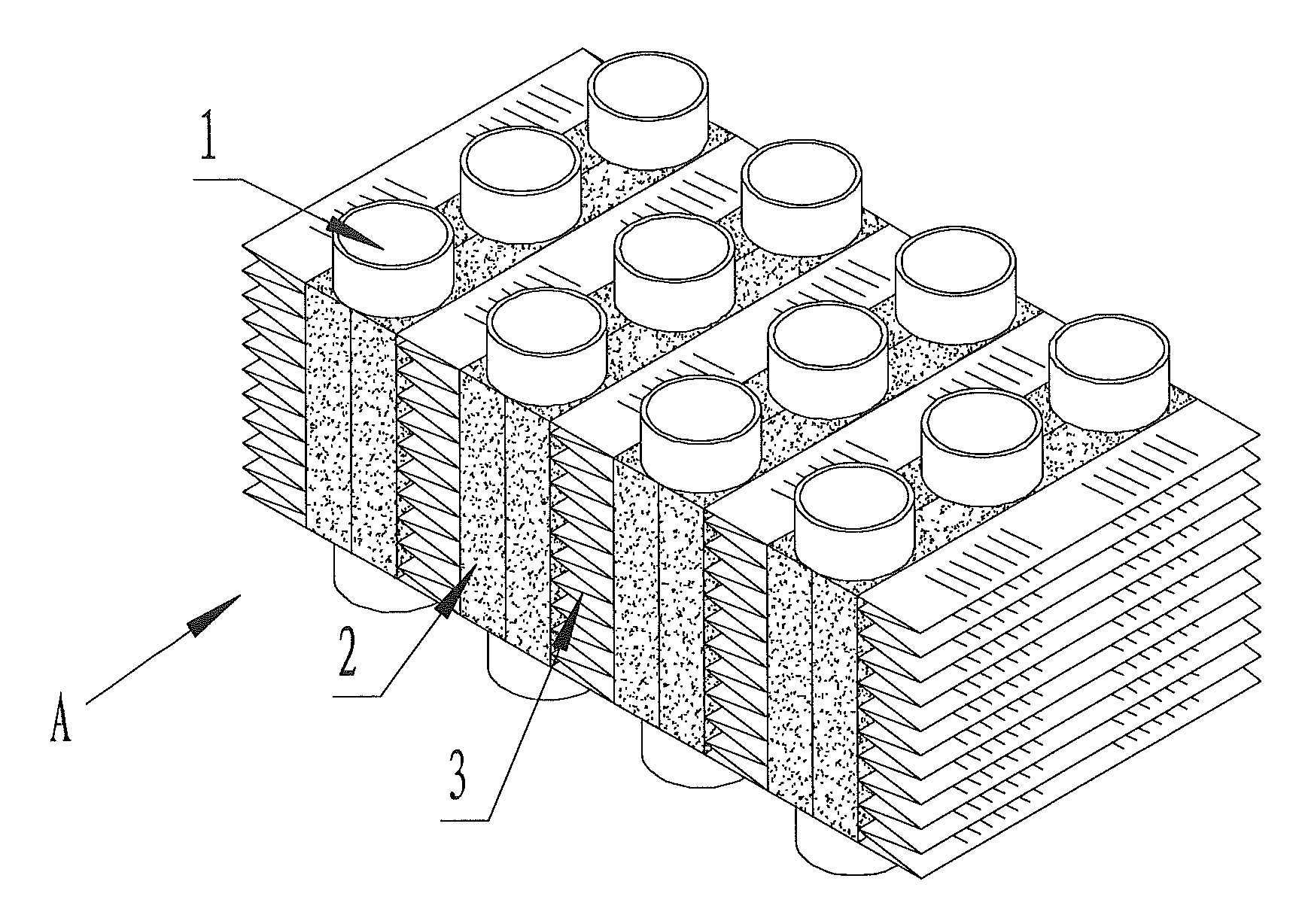

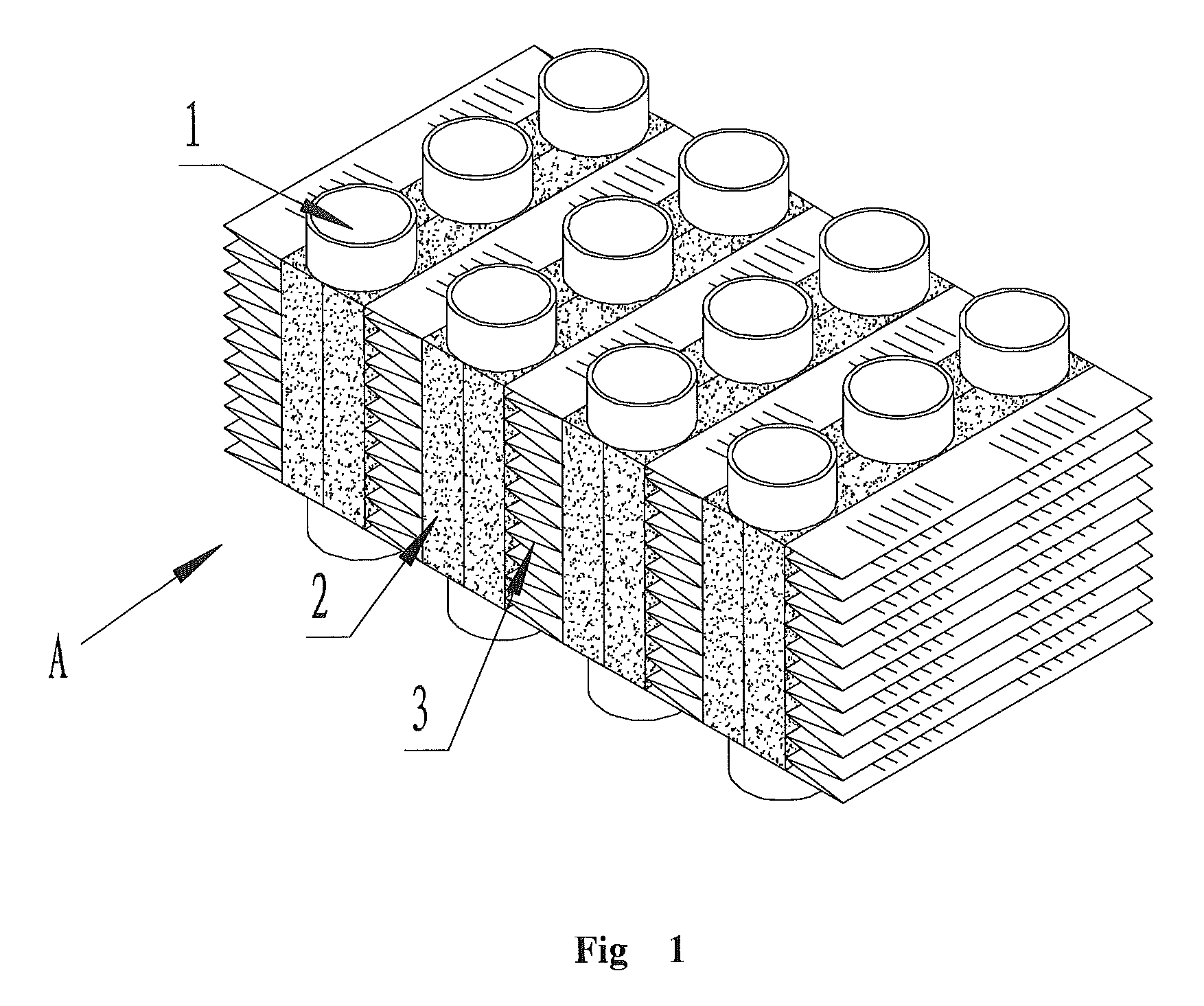

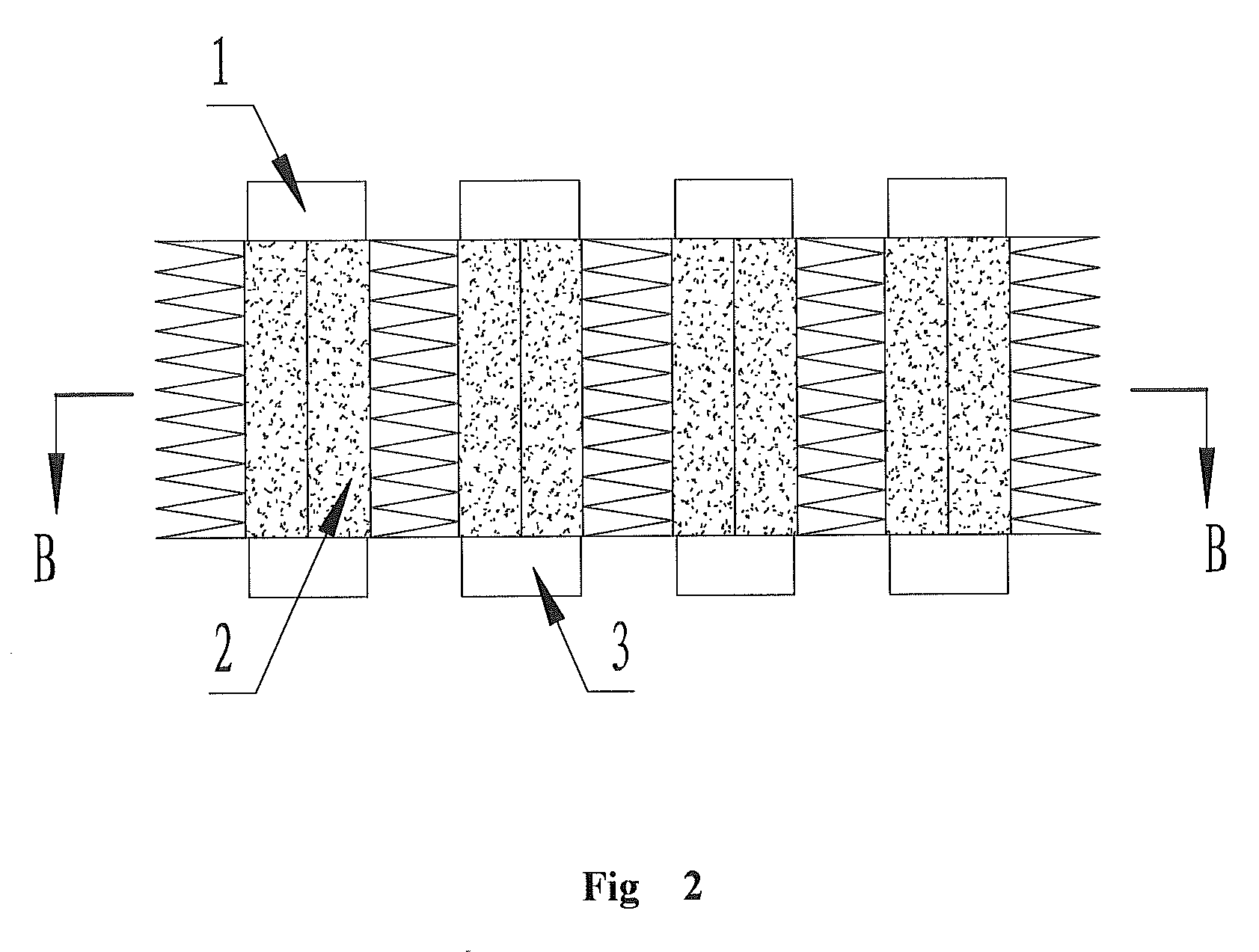

[0012]Referring to FIG. 1, the tube-strip type heat exchange unit with high pressure resistance of the present invention comprises a plurality of tubes (1), foam metal (2) and a plurality of heat dissipation fins (3). Tubes (1) and heat dissipation fins (3) are spaced arranged. Foam metal (2) is located in the interspace between tubes (1) and the superface of heat dissipation fins (3). Solder is disposed between tubes (1) and foam metal (2), and between foam metal (2) and heat dissipation fins (3). So tubes (1), foam metal (2) and heat dissipation fins (3) are jointed by soldering to form the heat exchange unit.

[0013]In details, the diameter and wall thickness of tubes (1) could be modified according to the volume and pressure resistance requirement for the heat exchange unit. Tubes (1) could be arranged in a single line or in multiple lines, depending on the thickness re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com