Steam rotary all-in-one machine and method for drying high-humidity and high-viscosity materials

An integrated machine and material technology, applied in the drying of granular materials, the preliminary treatment of promoting the drying of solid materials, non-progressive dryers, etc., can solve the problems of increased cost, complex process flow, limited heat exchange area, etc. Improve efficiency, simple operation and maintenance, and enhance the effect of mass transfer and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

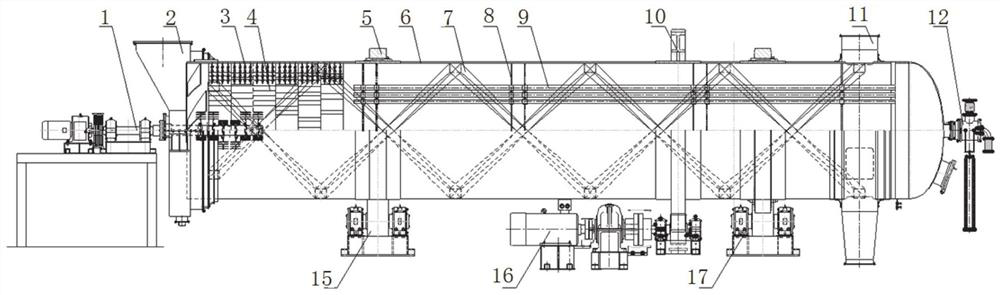

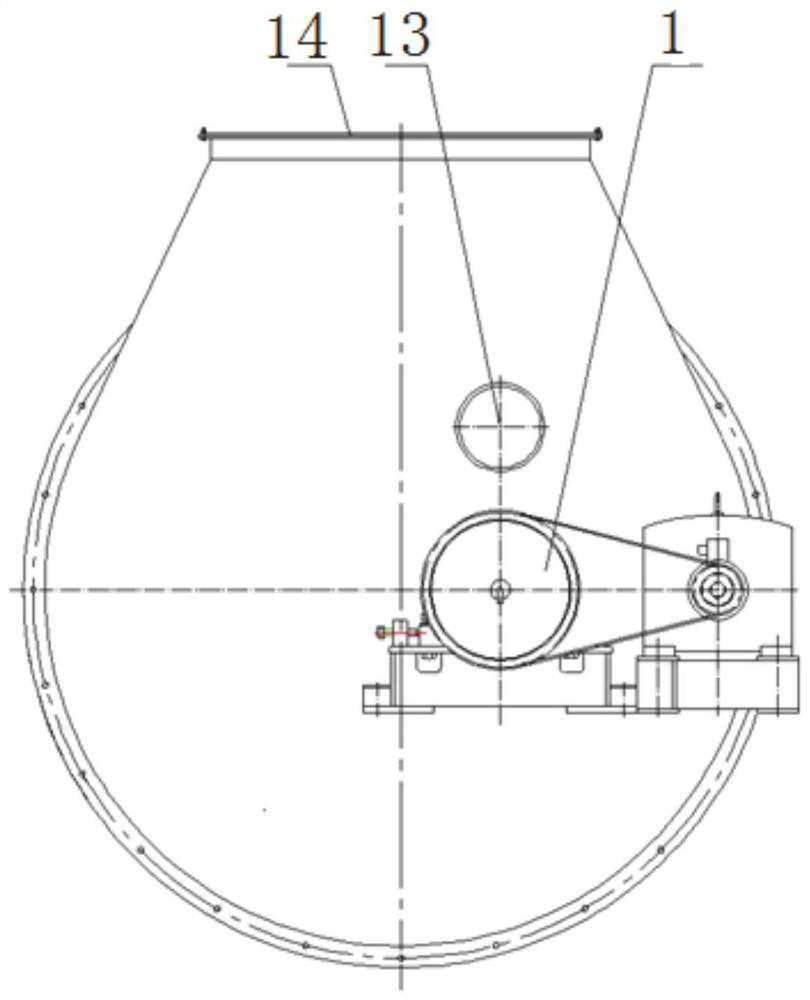

[0047] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, Embodiment 1 of the present invention provides a steam rotary integrated machine for drying high-humidity and high-viscosity materials, including: an end breaking device 1, a feeding cover 2, and a cylinder 6;

[0048] The feed cover 2 communicates with the feed end of the cylinder 6, the end breaking device 1 is arranged on the feed end of the cylinder 6, the feed cover 2 is provided with a feed port 13 and an air inlet 14, and the end The dispersing device 1 rotates at a high speed, and the rotating speed is adjustable.

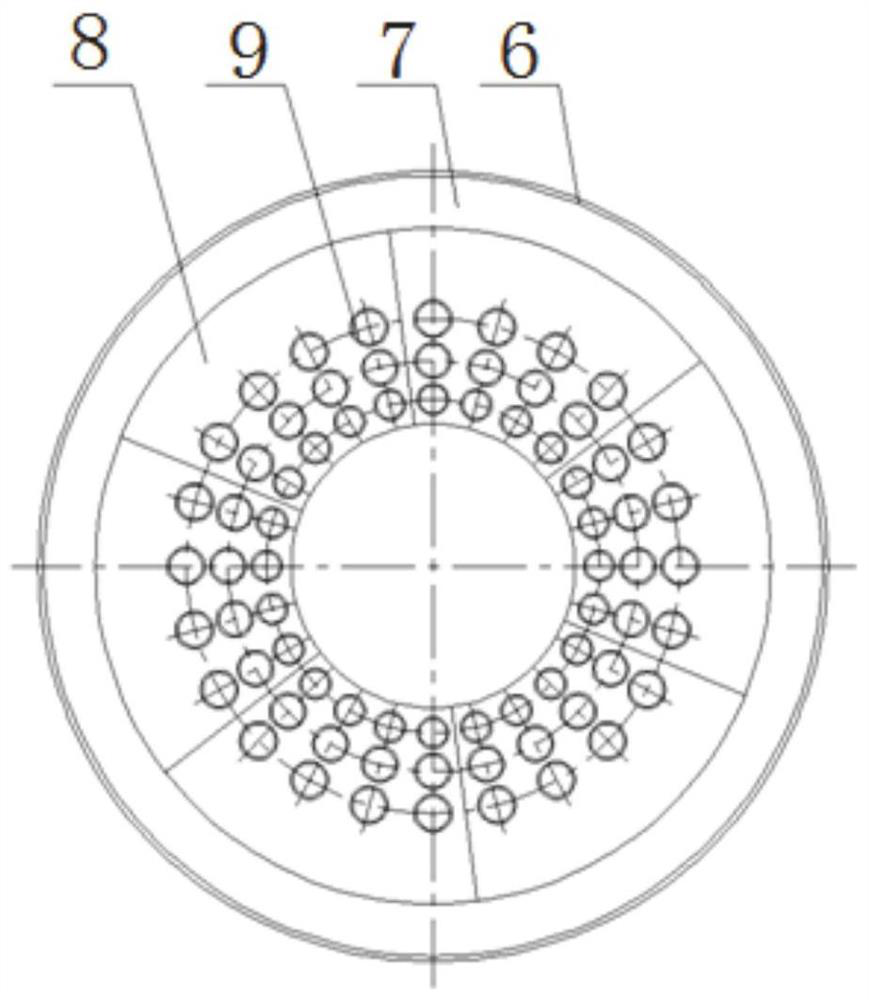

[0049] A material guide plate and a plurality of copying boards 4 are arranged on the inner wall of the cylinder 6 near the feeding end of the cylinder 6, and a plurality of chains 3 are arranged between adjacent copying boards 4, and the middle section and / or rear of the cylinder 6 The end is provided with a steam heat exchange tube 9;

[0050] It can be understood that in some oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com