Capacitive pressure difference sensor and output characteristic calculation method thereof and manufacturing method therefor

A differential pressure sensor, capacitive technology, used in fluid pressure measurement, calculation, and instrumentation using capacitance changes, which can solve problems such as temperature effects and complex sensor manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principle of differential pressure measurement and the manufacturing method of the sensor of the present invention will be described below in conjunction with the accompanying drawings and through corresponding calculation formulas.

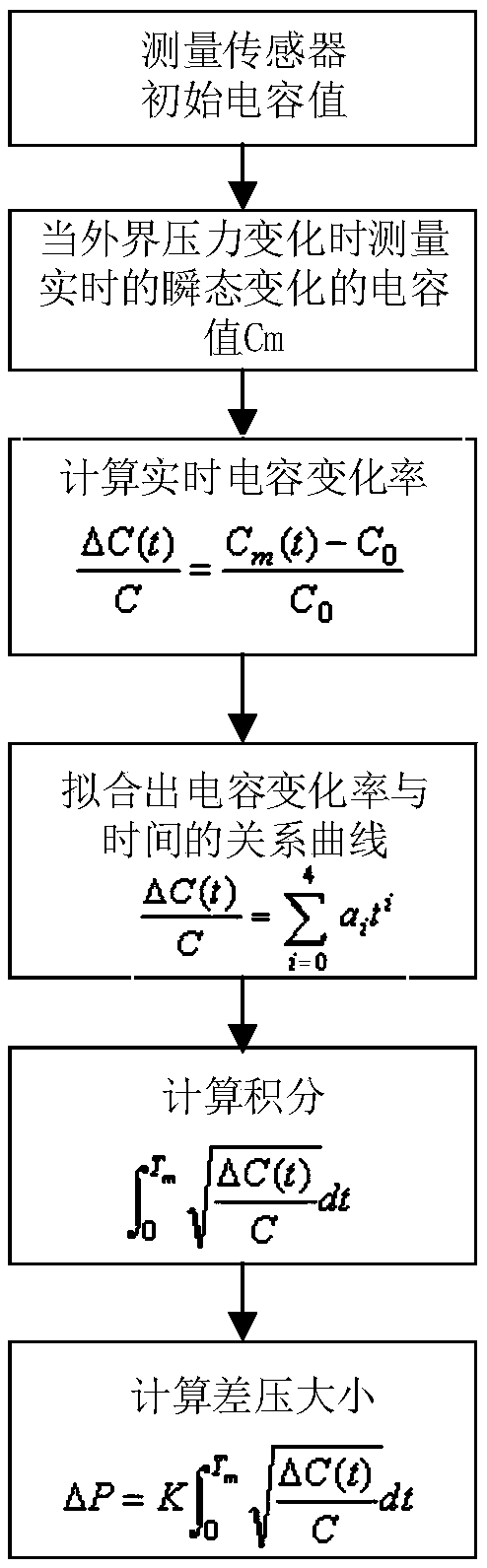

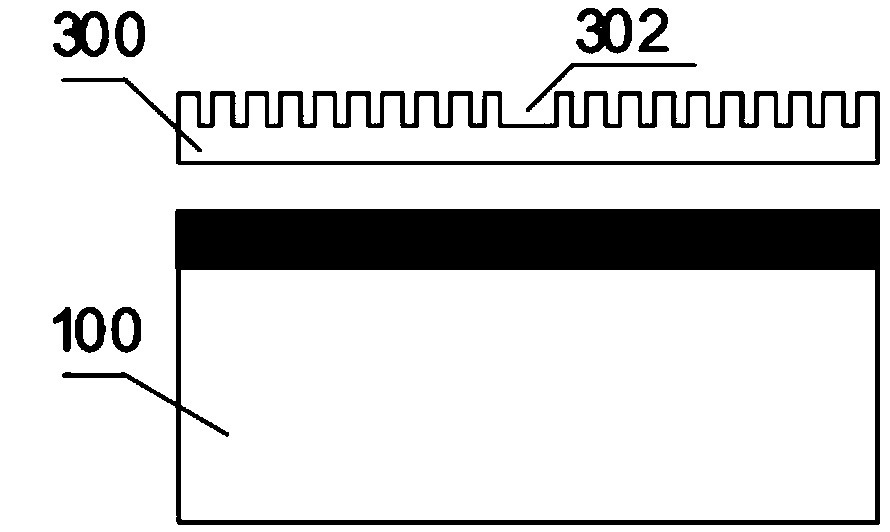

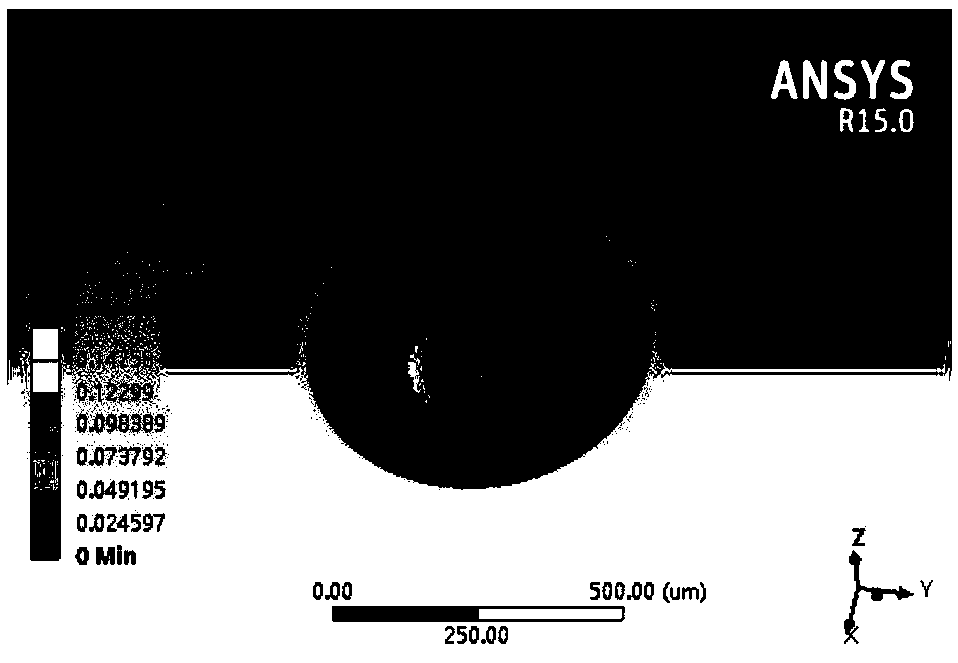

[0047] The output characteristic calculation method of the capacitive differential pressure sensor for real-time dynamic pressure measurement of the present invention comprises the steps of: obtaining the capacitive sensor according to the pressure difference on both sides of the silicon layer 105 of the pressure-sensing film and the change of the pole distance between the pressure-sensing film and the electrode The capacitance C m According to the theoretical formula of the plate and shell, calculate the deflection of the deformation around the circular pressure-sensitive film, and obtain the relative change rate of the capacitance under any differential pressure; obtain the change of the air pressure of the bulk silicon cavity 103 fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com