Blade detection method based on blade load analysis

A detection method and blade technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of increasing the manpower and material resources operation and maintenance costs of wind farms, unfavorable healthy development of the wind power industry, and economic losses of wind farms, etc. problem, to achieve the effect of improving planning, optimizing boom model, and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The invention provides a blade detection method based on blade load analysis, which can realize accurate detection of fan blade defects and reduce economic losses caused by fan blade failures, thereby effectively protecting fan blades and prolonging the use of fan blades Life, increase fan operating efficiency.

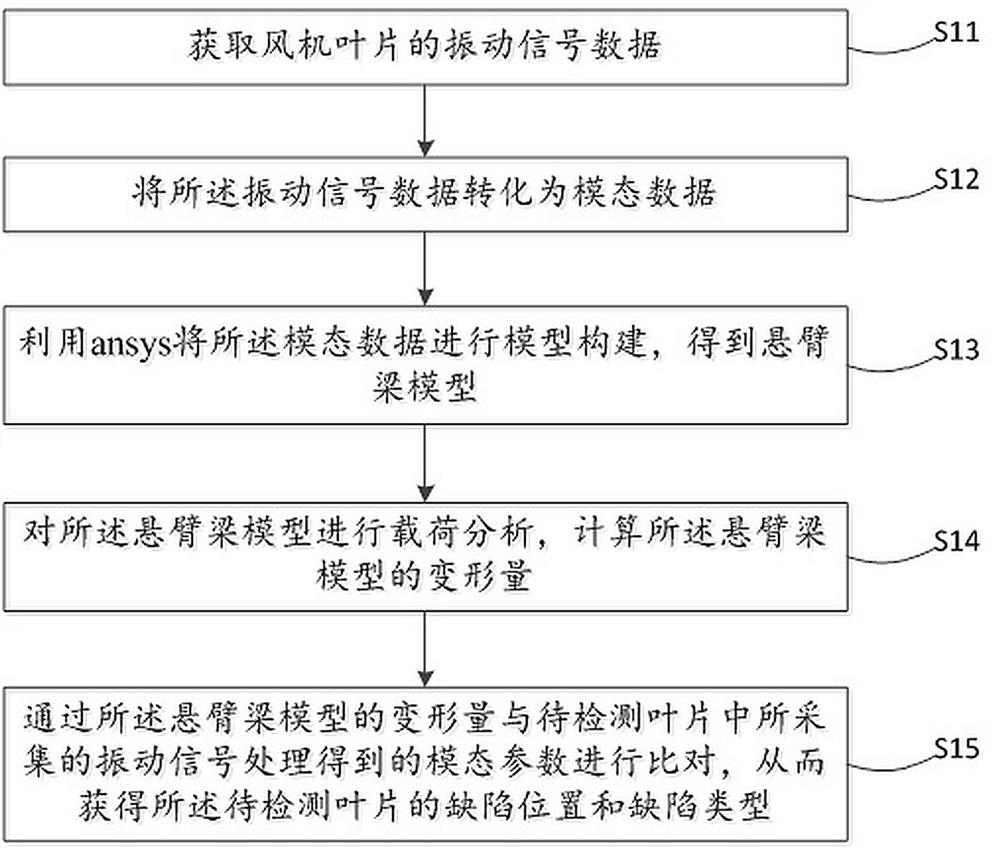

[0036] refer to figure 1 Shown is a schematic flowchart of a blade detection method based on blade load analysis provided by an embodiment of the present invention.

[0037] In this embodiment, the method includes:

[0038] S11. Obtain vibration signal data of fan blades.

[0039] Wherein, the step of obtaining the vibration signal data of the fan blade comprises:

[0040] By installing fiber grating sensors or strain gauge sensors on the fan blades, the status of the fan blades is monitored in real time to obtain vibration signal data of the fan blades.

[0041] In this embodiment, it is preferable to install a fiber grating sensor on the fan blade to monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com