Thin-walled cylinder mirror image cutting modeling method based on shell theory

A modeling method, thin-walled tube technology, applied in the field of thin-walled tube mirror cutting modeling based on shell theory, can solve the problem of complex response of thin-walled mirror processing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] A thin-wall cylinder mirror image cutting modeling method based on shell theory of the present invention will be described in detail below with reference to the embodiments and drawings.

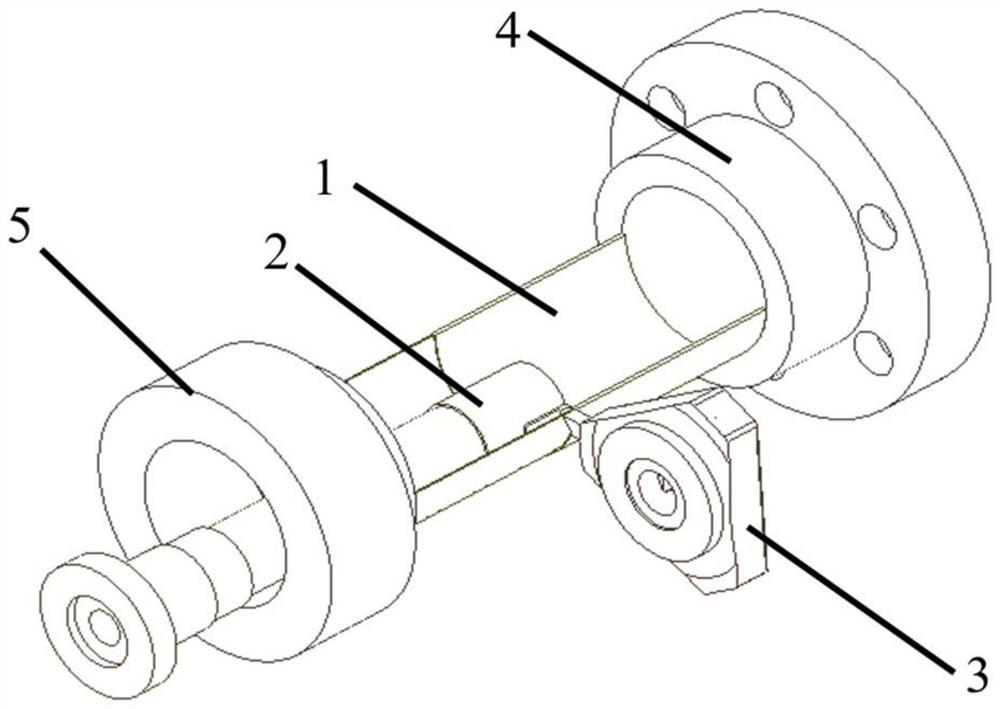

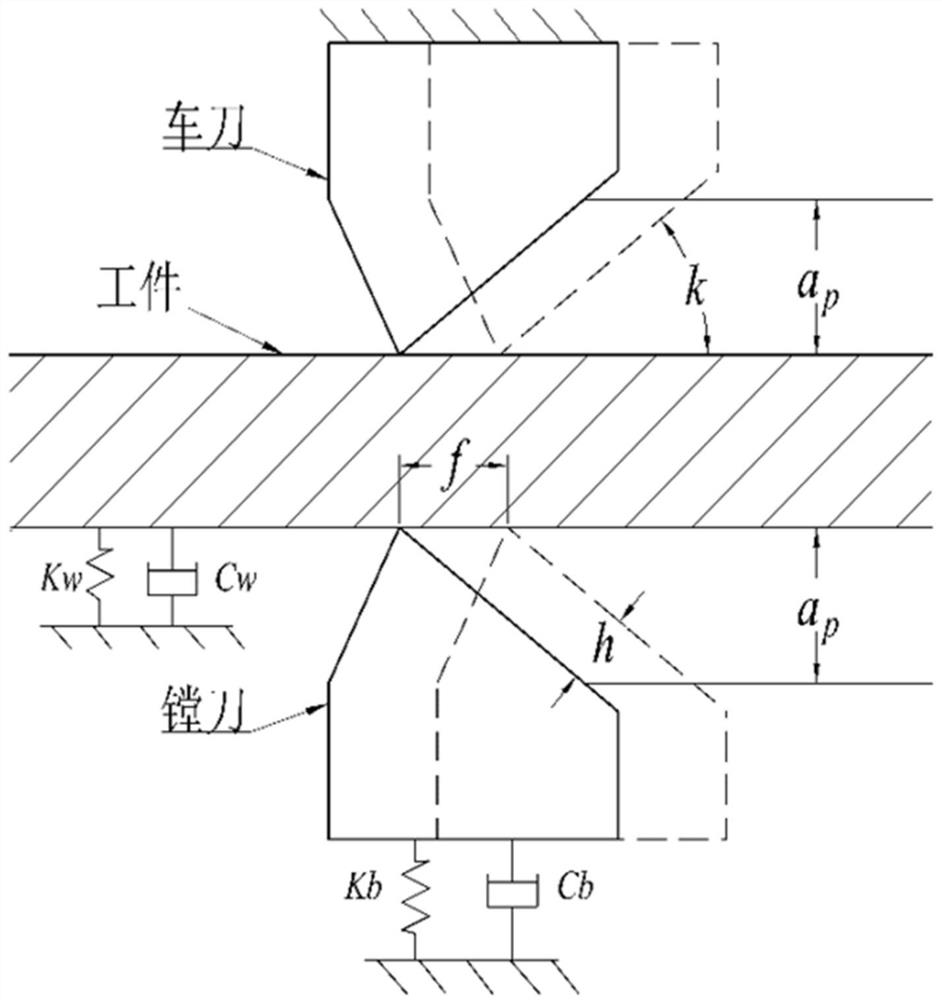

[0085] Such as figure 1 As shown, the thin-wall mirror image processing system is mainly composed of an outer circle turning tool 3, an inner circle boring bar 2, a thin-wall cylinder 1, a machine tool spindle 4 and a machine tool tail top 5. The rigidity of the outer turning tool 3 is much higher than that of the cantilever boring bar 2 and the thin-walled cylinder 1, and the vibration in the cutting system is small, so the outer turning tool is equivalent to a rigid body, and the inner boring bar and thin-walled workpiece are equivalent to a flexible body body, get as figure 2 The simplified model shown.

[0086] Model the system dynamics of the workpiece:

[0087] 1. Simplified model of workpiece system

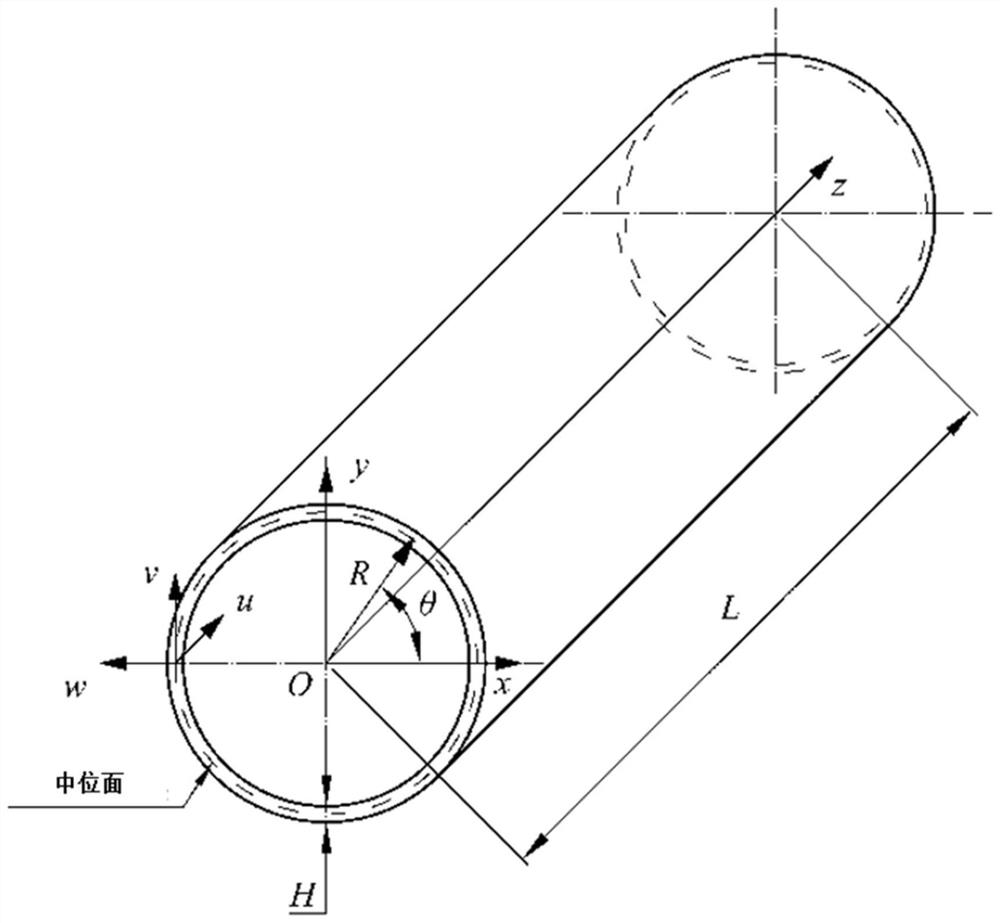

[0088] The processing object of this process system is a thin-walled cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com