A Calculation Method for Warping Deformation of Plate Parts Caused by Residual Stress Release

A technology of residual stress and calculation method, which is used in the calculation of warping deformation of plate parts, and the calculation field of warping deformation, to achieve the effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

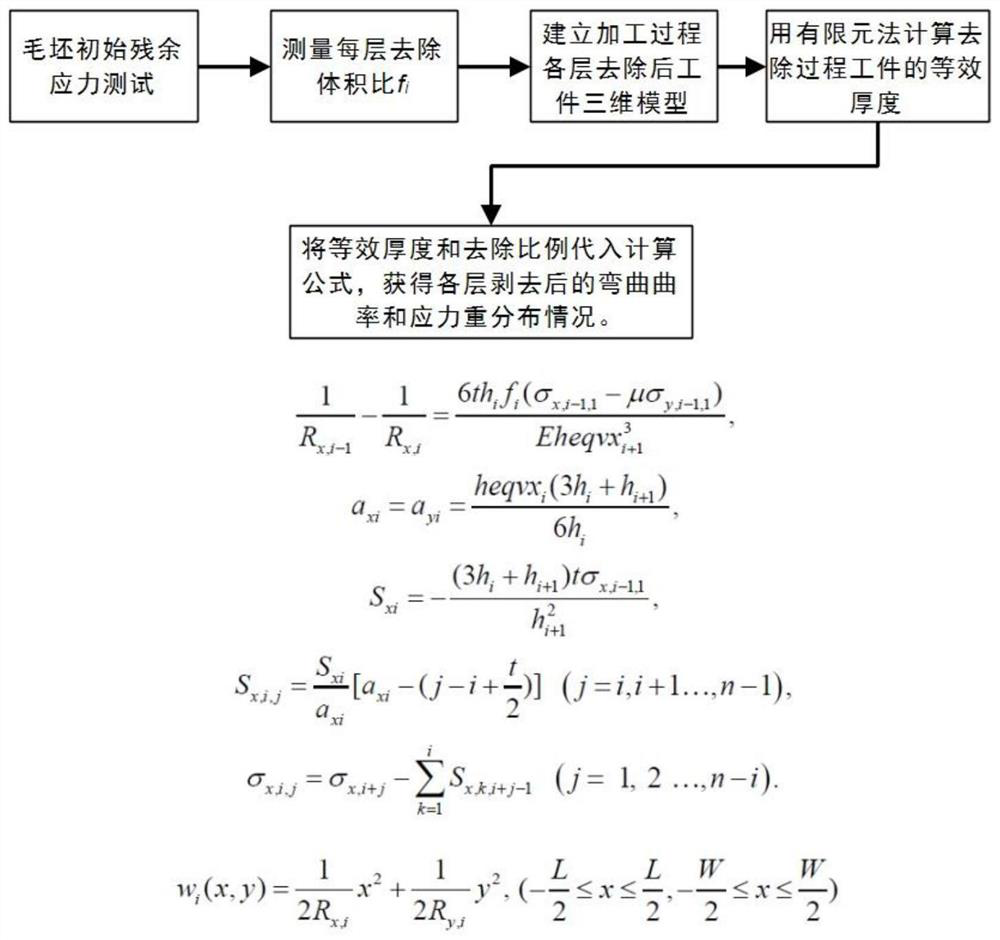

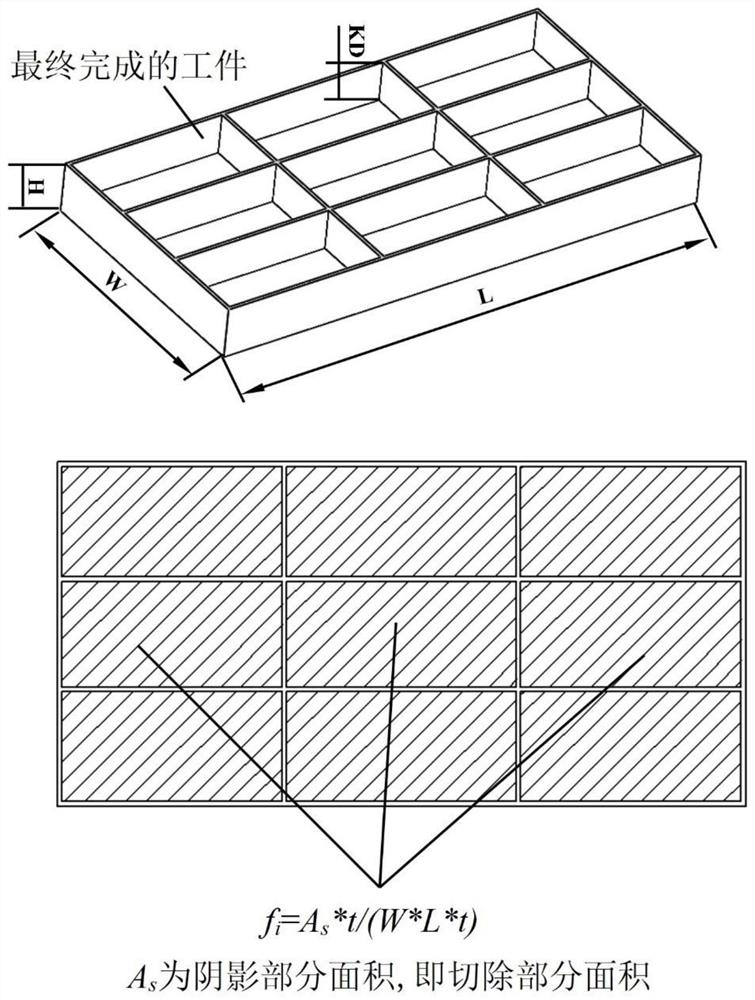

[0069] Attached below figure 1 The method flow of the present invention is further described so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly. Among them, attached figure 2 The described example of a plate-type workpiece to which the method is applicable is only used to explain the present invention, and cannot be construed as a limitation to the present invention.

[0070] Step 1: Obtain the residual stress distribution of each layer of the rectangular blank along the layer depth direction through the residual stress measurement method, and each layer should have residual stress values in both X and Y directions;

[0071] Step 2: In the 3D modeling software, according to the 3D model of the part and the blank, obtain the removal ratio f of each layer during the layer-by-layer material removal process of the part i ( figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com