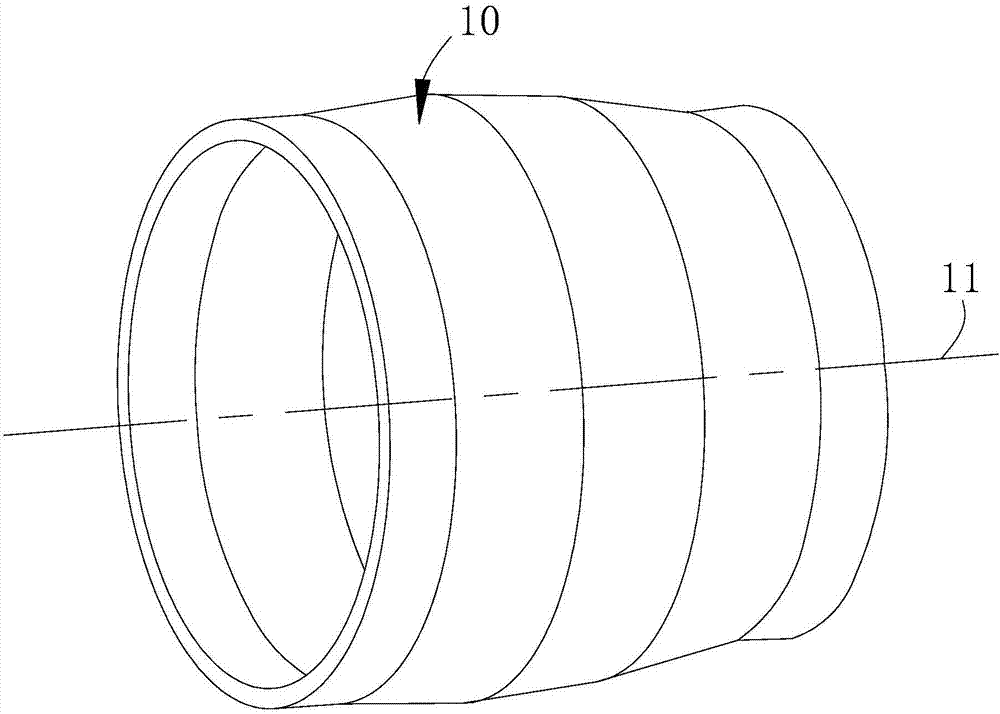

Large-size and thickness-changing revolved body precast body and manufacturing method thereof

A technology of variable thickness and preform, applied in the direction of fabric, textile, textile and paper making, to achieve the effect of continuous manufacturing, high efficiency and unlimited diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

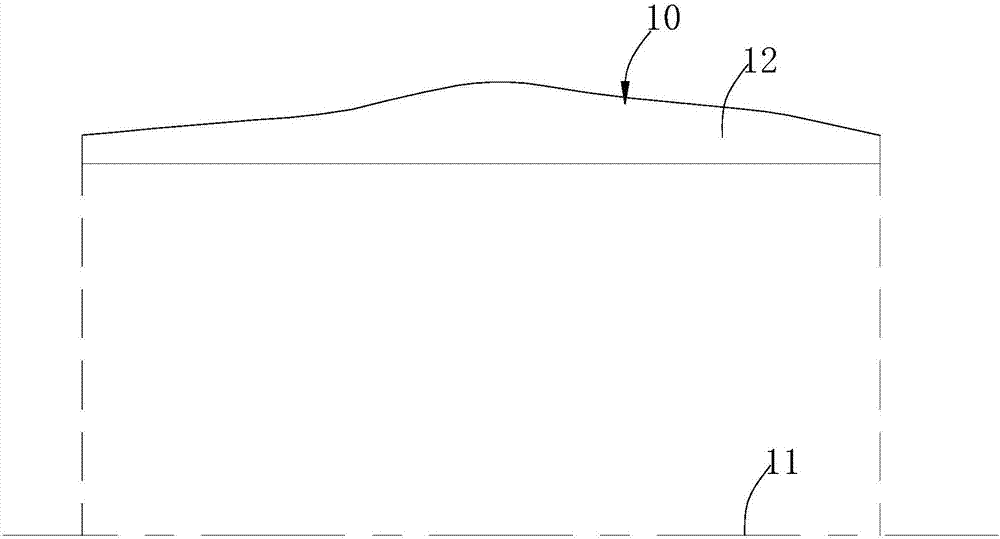

[0041] The specific preparation method of the above-mentioned large-size variable-thickness revolving body prefabricated body 10 is described below, and the following steps are adopted:

[0042] (1) Determine the dimensional parameters of the variable-thickness revolving body prefabricated body 10 to be produced;

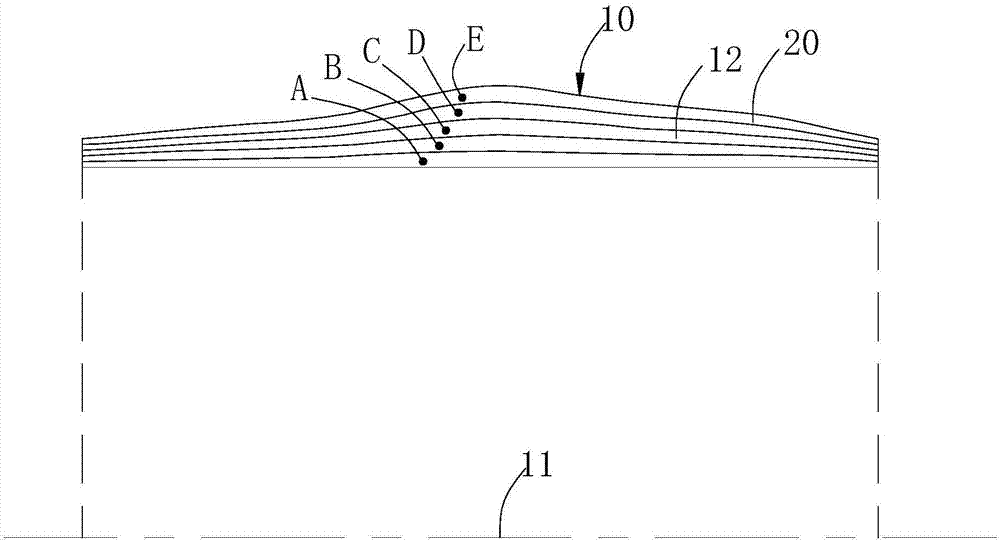

[0043] (2) Determine the number of uniform layers of the variable-thickness revolving body prefabricated body 10 to be produced, which is divided into 5 layers in this embodiment, and determine the size of the variable-thickness revolving body prefabricated body 20 based on the size parameters of the variable-thickness revolving body prefabricated body 10 parameter;

[0044] (3) Weaving variable thickness prefabricated body 20 on the two-dimensional loom and finishing;

[0045] (4) See Figure 8 , the variable-thickness preform 20 is continuously wound on the rotary mandrel 30 to obtain the variable-thickness rotary preform 10 .

[0046] In this embodiment, when ...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, the difference lies in the thickness variation method of the variable thickness preform 20 .

[0056] In this embodiment, the method for changing the thickness of the variable-thickness preform 20 is specifically a method for changing the number of layers of warp yarns. An exemplary description is given below.

[0057] The variable-thickness preform 20 of this embodiment is a shallow cross-bending layered structure, and the method of changing the number of warp layers refers to changing the number of warp layers along the weft direction as the thickness of the variable-thickness preform changes. see Figure 6 , Figure 6 It is a partial weaving schematic diagram of the method of variable warp yarn layers. Along the extension direction of arrow F2, the thickness of the variable thickness preform becomes thicker continuously. As the thickness increases, the number of layers of warp yarn S3 increases. Figure 6 , ex...

Embodiment 3

[0062] This embodiment is basically the same as Embodiment 1, the difference lies in the thickness variation method of the variable thickness preform 20 .

[0063] In this embodiment, the method of changing the thickness of the variable-thickness preform 20 is specifically a method of combining warp yarn specification and warp yarn layer number. An exemplary description is given below.

[0064] The variable thickness preform 20 of this embodiment is a shallow cross-bending layered structure, and the method of combining the variable warp specification and the variable warp layer refers to changing the thickness of the variable thickness preform while changing the warp specification along the weft direction. Vary the number of warp layers. see Figure 7 , Figure 7 It is a partial weaving schematic diagram of the method of combining variable warp yarn specifications and variable warp yarn layers. Along the extension direction of arrow F3, the thickness of the variable thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com