Technology and apparatus for making jet-type centrifugal rotary mould of great non-crystal ring parts

A centrifugal rotary mold and manufacturing process technology, which is applied in the field of jet centrifugal rotary mold manufacturing process and equipment for annular bulk amorphous parts, can solve the problems of very strict requirements, difficult preparation and high cost, and achieves simple device structure and cooling speed. Fast and productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

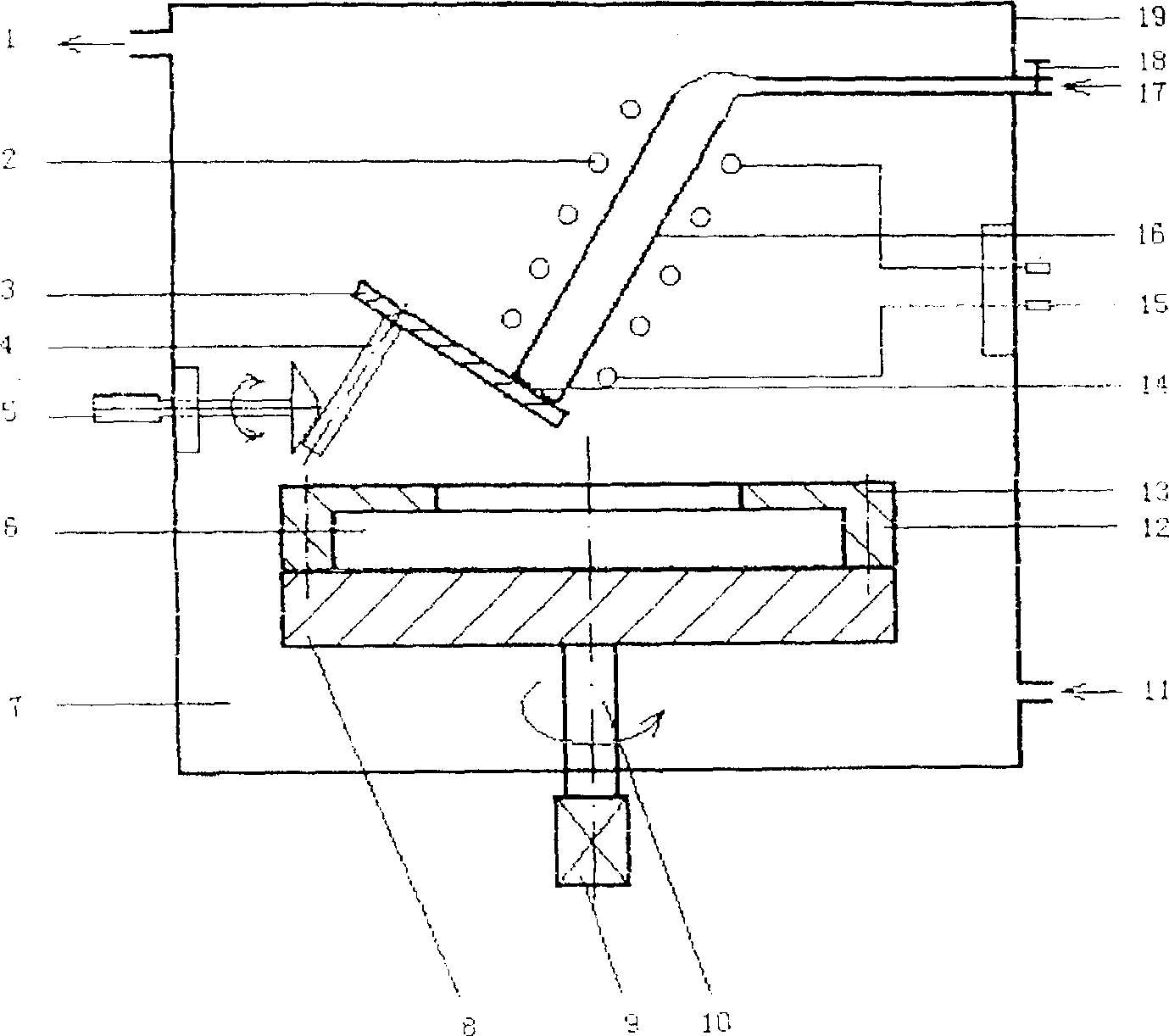

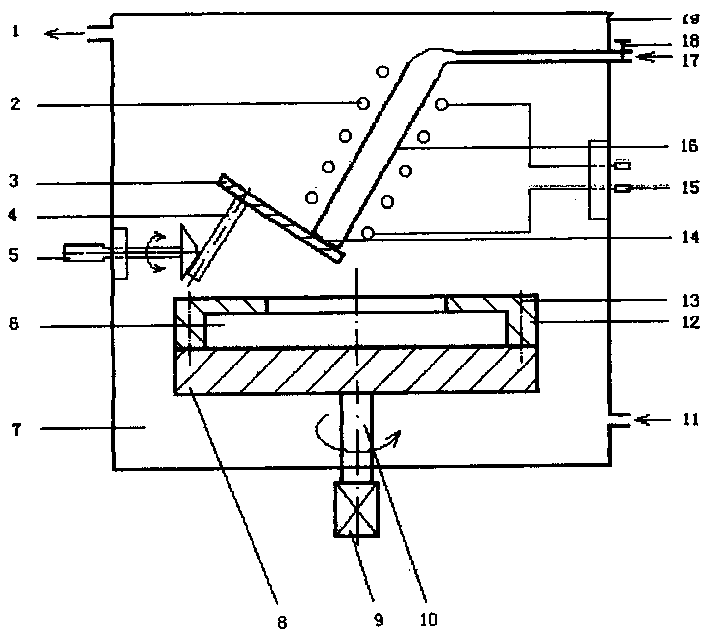

[0012] When the device is working, first put the master alloy into the crucible, and vacuumize the system through the interface [1]. After the vacuum degree reaches 10-5 Torr, fill in argon or helium with an atmospheric pressure through the interface (11); then turn on the intermediate frequency The power supply heats and melts the alloy, and after the temperature reaches the range of 10 to 300 degrees above the melting point of the alloy, keep it warm for 5 to 10 minutes; turn the baffle (3) to open the nozzle hole (14) at the bottom of the crucible, and open the throttle valve (17) at the same time, so that The crucible is connected with the argon gas of five to ten atmospheres, and the liquid alloy in the crucible is ejected from the nozzle hole (14) under the pressure of five to ten atmospheres, and injected into the combined rotary mold (12) rotating at high speed. Under the action of centrifugal force, the mold cavity (6) is filled and solidified to form a ring-shaped bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com