Rubber rolling device for producing soft polyurethane (PU) skylight sun shield

A sun visor and roller glue technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems that the amount of glue cannot be adjusted locally, and the glue is easy to penetrate, so as to solve the problem of glue penetration, high efficiency, and less waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

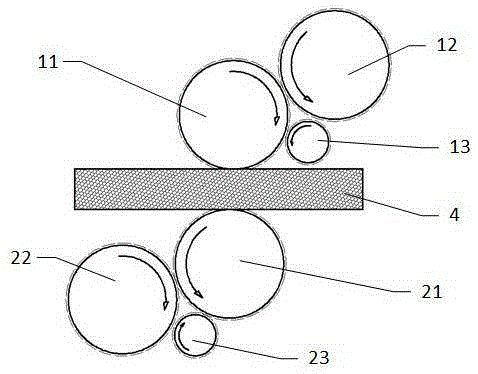

[0026] like Figure 4 As shown, the roller rubber device of the soft PU sunroof sunshade includes two sets of rollers, the upper roller includes the first rubber roller 11 and the second rubber roller 12, the lower roller includes the first rubber roller 21 and the second rubber roller 22, and the PU board 4 is located between the two sets of rollers, and the upper and lower surfaces are in contact with the first rubber rollers 11 and 21 respectively. On the following group of rollers, a third rubber roller 23 is also provided. The first rubber roller and the second rubber roller rotate in opposite directions, and the glue liquid passes through the gap between the two rubber rollers and transfers to the PU board. The rotation direction of the third rubber roller is also opposite to that of the first rubber roller, and a smaller gap is kept, so that a part of glue is trapped between the first rubber roller and the third rubber roller, so that less glue is transferred to the PU...

Embodiment 2

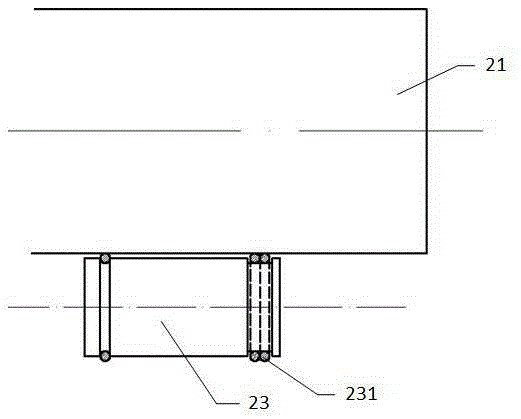

[0031] like Image 6 As shown, the third rubber roller 23 is arranged at a position close to the second rubber roller 22 . The glue liquid accumulated between the first rubber roller 21 and the third rubber roller 23 can be taken away by the second rubber roller 22, and returns to the glue storage area formed by the top of the first rubber roller 21 and the second rubber roller 22, be reused to prevent the glue solution intercepted by the third rubber roller 23 from being wasted.

[0032] If the 3rd cot roller is set between the first cot roller 11 and the second cot roller 12 of upper surface gluing, be subjected to the influence of the space formed by the second cot roller 12 below and the first cot roller 11 and the PU foam board 4 limit, the diameter of the third rubber roller must be very small.

[0033] In this embodiment, the third rubber roller 23 is arranged on the lower group of rollers, the space is sufficient, and the diameter is not limited, and a rubber roller ...

Embodiment 3

[0035] like Figure 7 As shown, the third rubber rollers 13 and 23 are respectively arranged on the upper and lower two groups of rollers, and the amount of rubber rollers on the front and back sides of the PU foam board can be adjusted respectively, and the degree of freedom of process adjustment is greater.

[0036] By adopting the technical scheme of the present application, the glue coming out from the gap formed by the first rubber roller and the second rubber roller contacts with the third rubber roller, and the amount of glue is reduced, which can prevent the sunroof sun visor from showing through on the back side when the thickness of the sunshade is very thin. glue phenomenon. The design of the third rubber roller close to the second rubber roller can take away the glue retained by the third rubber roller by the second rubber roller. The length of the third rubber roller is short, the number may be more than one, and the position and number may be adjusted according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com