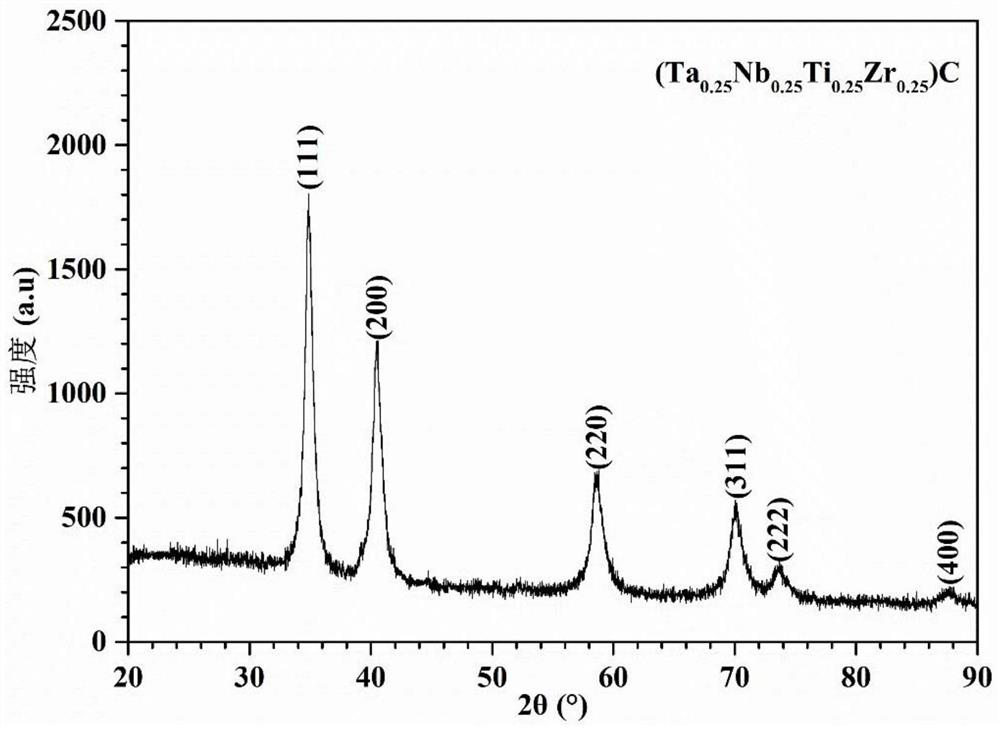

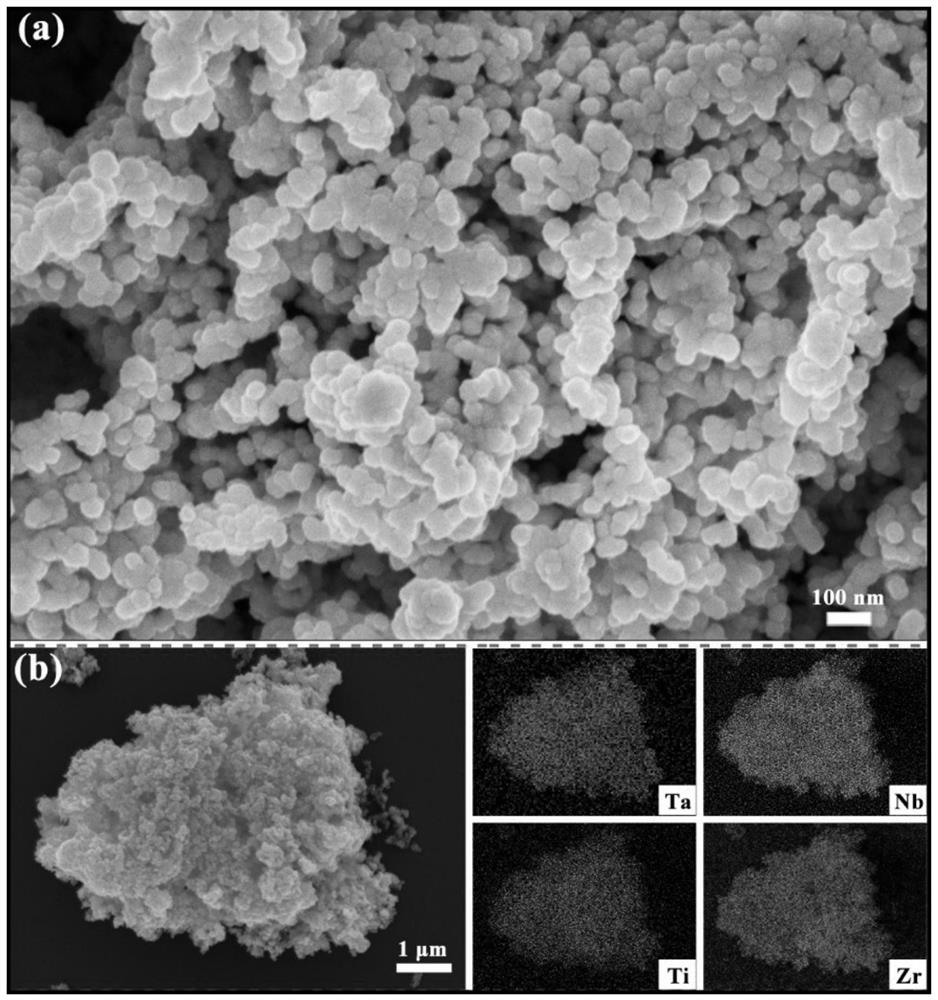

High-entropy carbide ceramic nano-powder as well as preparation method and application thereof

A nano-powder and carbide technology, applied in the field of high-entropy powder materials, can solve the problems of high oxygen impurity content, large powder particle size, uneven element distribution, etc., and achieve low oxygen impurity content, low equipment requirements, The effect of uniform distribution of metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of high-entropy carbide ceramic nanopowder, its preparation method comprises the following steps:

[0038] 1) Add 5.93g of Cr 2 o 3 Powder, 6.16g of TiO 2 Powder, 17.23g of Ta 2 o 5 Powder, 10.37g of Nb 2 o 5 Add the powder, 3.94g of carbon powder and 24.98g of magnesium powder into an agate mortar, grind for 60 minutes by hand, then add 26.20g of NaF, grind for 60 minutes by hand, and then pre-press into tablets under a pressure of 40MPa to obtain a mixed powder Tablet;

[0039] 2) Put the mixed powder into the crucible and put it into the tube furnace, vacuumize the tube furnace so that the value of the vacuum pressure gauge reaches -0.05MPa, keep the vacuum for 10 minutes, and observe whether the indication of the vacuum gauge changes, if there is no Changes indicate that the system is well sealed. This process is repeated six times, and then argon is introduced to normal pressure, and then the furnace temperature is raised from room temperature to 950 ...

Embodiment 2

[0042] A kind of high-entropy carbide ceramic nanopowder, its preparation method comprises the following steps:

[0043] 1) 9.61g of ZrO 2 Powder, 6.16g of TiO 2 Powder, 17.23g of Ta 2 o 5 Powder, 10.37g of Nb 2 o 5 Add the powder, 3.94g of carbon powder and 27.30g of magnesium powder into an agate mortar, grind for 45 minutes by hand, then add 35.37g of NaF, grind for 45 minutes by hand, and then pre-press into tablets under a pressure of 30MPa to obtain a mixed powder Tablet;

[0044]2) Put the mixed powder into the crucible and put it into the tube furnace, vacuumize the tube furnace so that the value of the vacuum pressure gauge reaches -0.05MPa, keep the vacuum for 10 minutes, and observe whether the indication of the vacuum gauge changes, if there is no The change indicates that the system is well sealed. This process is repeated six times, and then argon is introduced to normal pressure, and then the furnace temperature is raised from room temperature to 1000 °C a...

Embodiment 3

[0049] A kind of high-entropy carbide ceramic nanopowder, its preparation method comprises the following steps:

[0050] 1) 9.61g of ZrO 2 Powder, 5.93g of Cr 2 o 3 Powder, 17.23g of Ta 2 o 5 Powder, 10.37g of Nb 2 o 5 Powder, 3.94g of carbon powder and 26.59g of magnesium powder were added to an agate mortar, ground for 30 minutes by hand, then 44.54g of NaF was added, ground for 30 minutes by hand, and then pre-pressed into tablets under a pressure of 20MPa to obtain a mixed powder Tablet;

[0051] 2) Put the mixed powder into the crucible and put it into the tube furnace, vacuumize the tube furnace so that the value of the vacuum pressure gauge reaches -0.05MPa, keep the vacuum for 10 minutes, and observe whether the indication of the vacuum gauge changes, if there is no The change indicates that the system is well sealed. This process is repeated six times, and then argon is introduced to normal pressure, and then the furnace temperature is raised from room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com