Square steel confined concrete arch center wall back filling bolting-grouting support system and construction method

A technology of confining concrete and filling behind the wall, which is applied in the direction of earth drilling, installation of bolts, mining equipment, etc., can solve the problems of insufficient steel arch support strength, etc., to avoid loss of bearing capacity, large adjustment space, and support high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is described in detail below in conjunction with accompanying drawing:

[0057] For tunnels with weak and broken surrounding rock, the step method, CD method, CRD method and double-side-wall pilot tunnel method are generally used for excavation. Taking the CRD method as an example, the present invention will be further described below in conjunction with the drawings and embodiments.

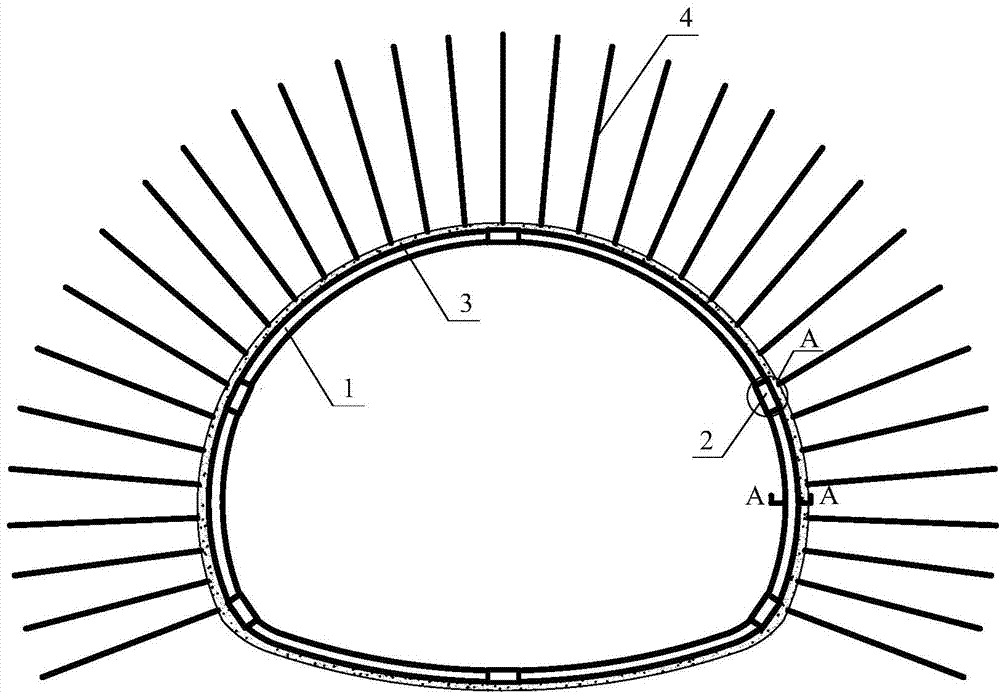

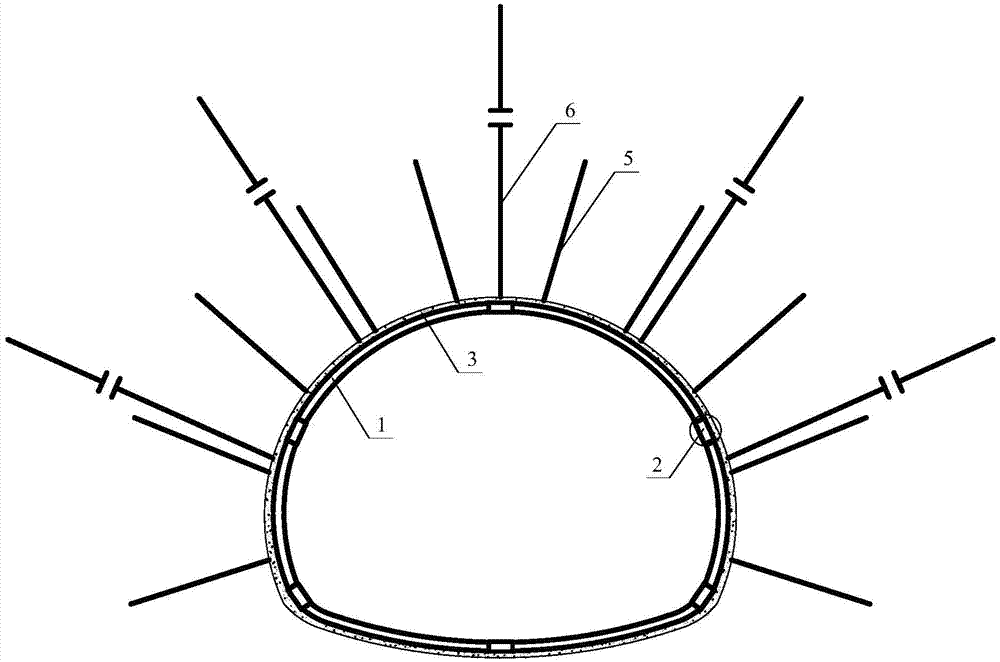

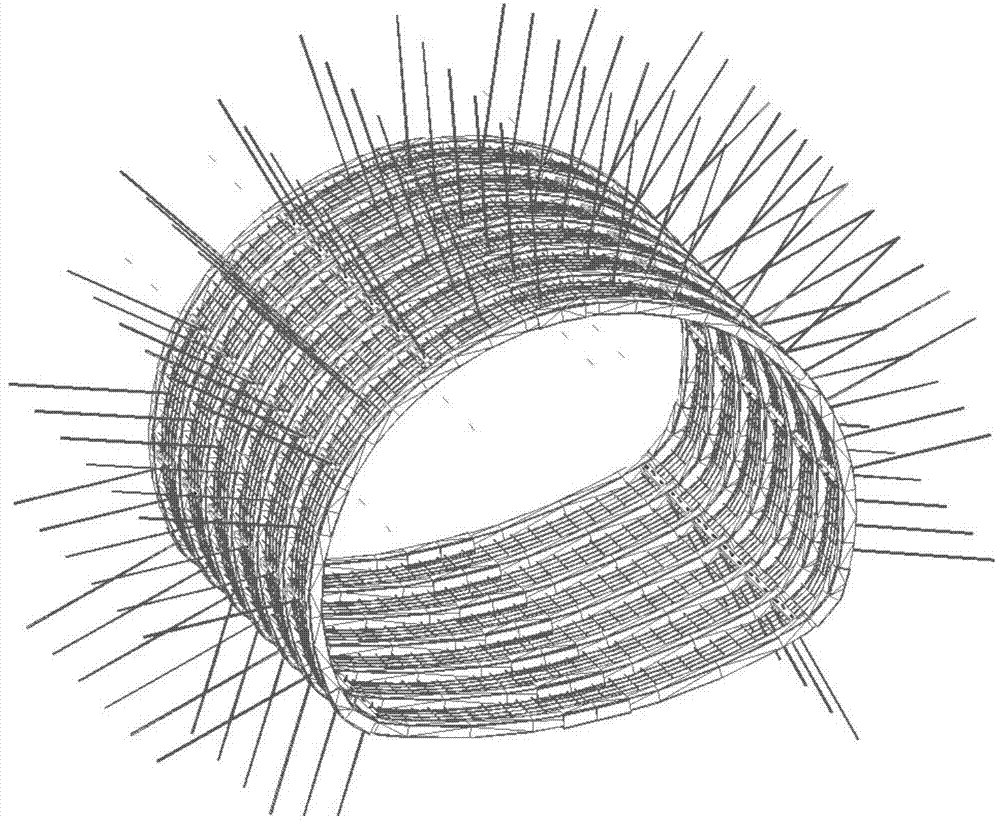

[0058] Such as Figure 1-6 As shown, the anchoring and grouting support system for square steel-constrained concrete arch walls mainly includes: square steel-constrained concrete arches 1, arch nodes 2, backfilling layer 3, high-strength anchors 4, and grouting anchors 5 , grouting anchor cable 6, longitudinal beam 7, steel mesh 8, high-strength and high-toughness anti-leakage membrane 9 and so on. Its characteristics are: the grouting material used for the grouting anchor rod 5 and the grouting anchor cable 6 is early-strength high-toughness cement or other chemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com