Electrode optimization placement method for improving stability of surrounding rocks in roadway

A technology of surrounding rock stability and layout method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of long electrochemical modification time and affecting the improvement of soft rock strength, and is beneficial to deformation and stress control , reduce the amount of deformation, and inhibit the deformation of the roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

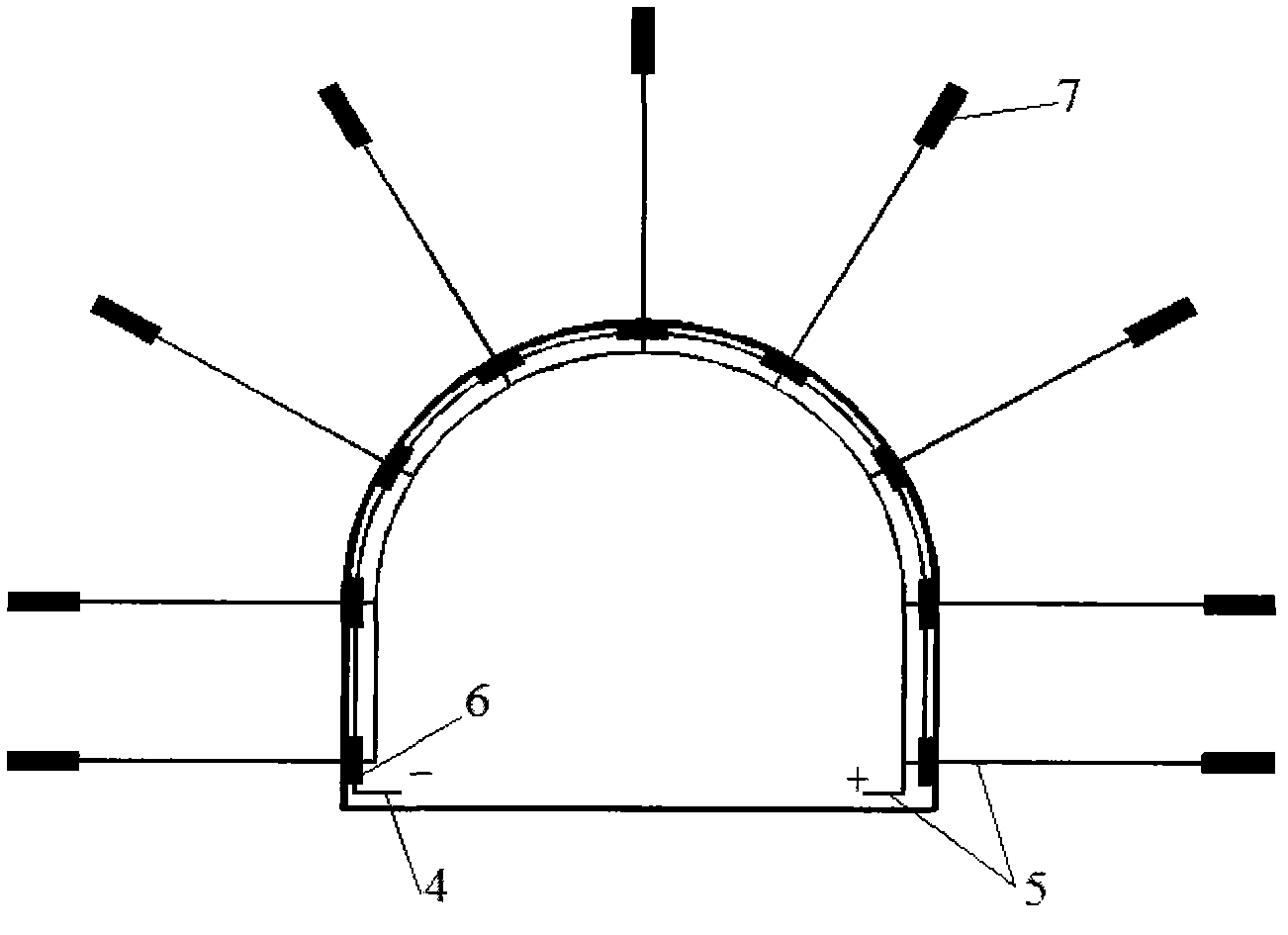

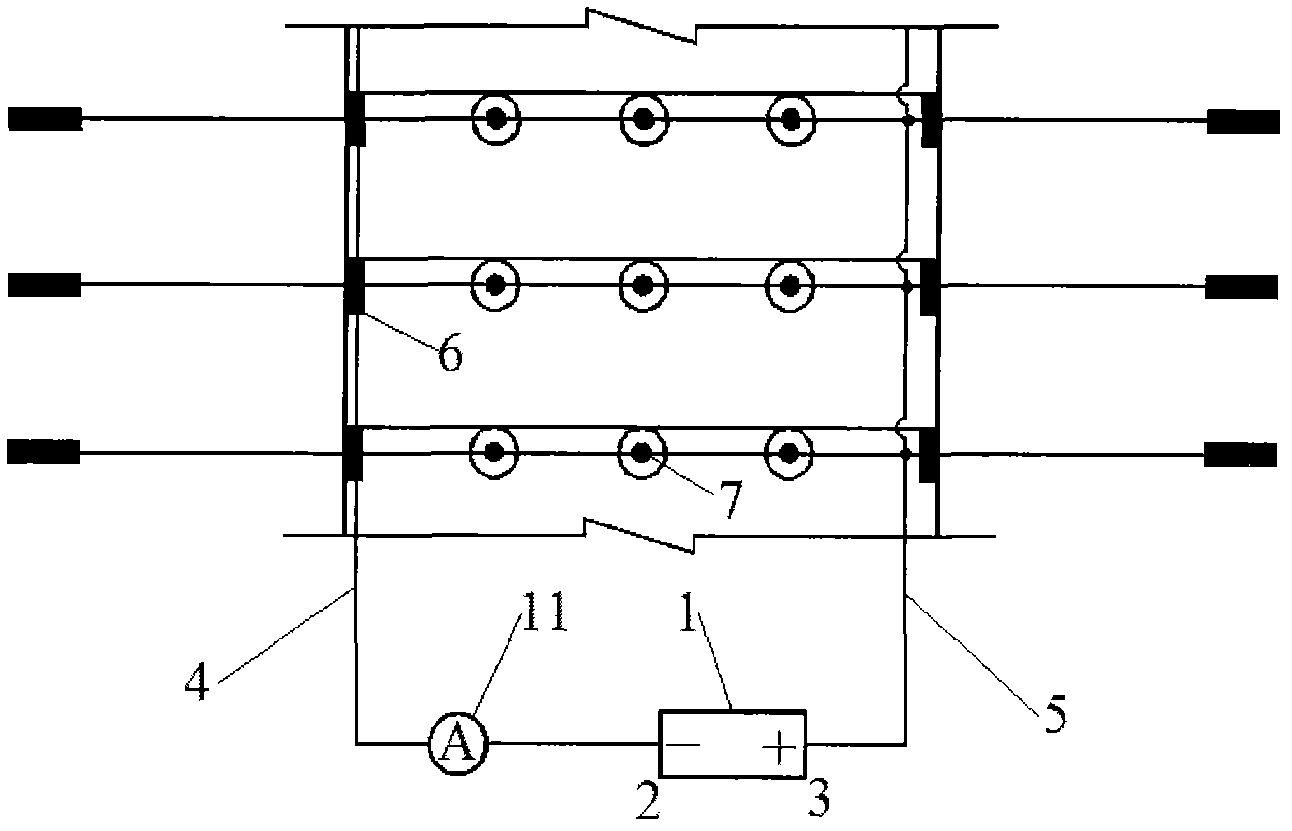

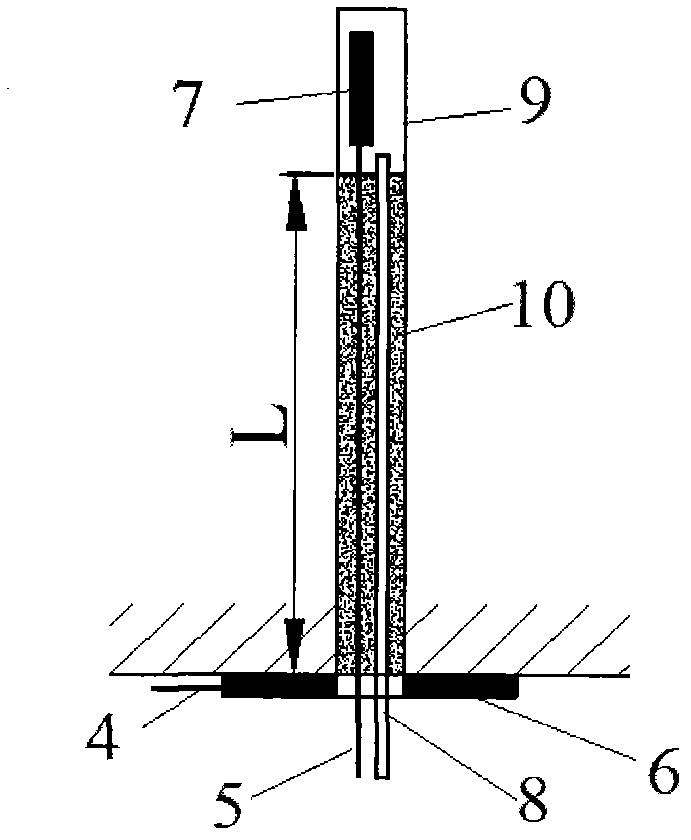

[0031] a) According to the characteristics of the surrounding rock of the roadway and its control requirements on the stability of the surrounding rock and the existing construction technology, drill a borehole 9 with a diameter of 28mm along the section perpendicular to the axis of the roadway, and the distance between the boreholes 9 along the circumference of the roadway, The row spacing along the roadway axis and the drilling length are both 0.5 times the radius of the arched roadway. A rod-shaped iron anode electrode 7 with a diameter of 20mm and a length of 500mm is placed in the deep part of the surrounding rock, that is, at the bottom of the drilling hole. That is, a disk-shaped iron cathode electrode 6 with a diameter of 200 mm and a thickness of 20 mm and a central hole diameter of 28 mm is fixed at the hole opening.

[0032] b) Use insulated wires 4 and 5 to connect the fixed cathode electrodes 6 at the openings of the drilled holes in the modification area and the a...

Embodiment approach 2

[0037] a) According to the characteristics of the surrounding rock of the roadway and its control requirements on the stability of the surrounding rock and the existing construction technology, drill a borehole 9 with a diameter of 42mm along the section perpendicular to the axis of the roadway, and the distance between the boreholes 9 along the circumference of the roadway, The row spacing along the axial direction of the roadway and the length of the borehole are both 0.8 times the width of the roadway. A rod-shaped copper anode electrode 7 with a diameter of 30mm and a length of 1000mm is placed in the deep part of the surrounding rock, that is, at the bottom of the borehole. A disc-shaped copper cathode electrode 6 with a diameter of 300mm and a thickness of 30mm and a central hole diameter of 42mm is fixed at the mouth;

[0038] b) Use insulated wires 4 and 5 to connect the fixed cathode electrodes 6 at the openings of the drilled holes in the modification area and the ano...

Embodiment approach 3

[0043] a) According to the characteristics of the surrounding rock of the roadway and its control requirements on the stability of the surrounding rock and the existing construction technology, drill a borehole 9 with a diameter of 36mm along the section perpendicular to the axis of the roadway, and the distance between the boreholes 9 along the circumference of the roadway, The row spacing along the axial direction of the roadway and the length of the drilled hole are both 1 times the height of the roadway. A rod-shaped copper anode electrode 7 with a diameter of 25 mm and a length of 800 mm is placed in the deep part of the surrounding rock, that is, at the bottom of the drilled hole. A disc-shaped iron cathode electrode 6 with a diameter of 250mm and a thickness of 25mm and a central hole diameter of 36mm is fixed at the orifice;

[0044] b) Use insulated wires 4 and 5 to connect the fixed cathode electrodes 6 at the openings of the drilled holes in the modification area and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com