Supporting structure for rock roadbed heightening and construction method

A technology for retaining structures and subgrades, which is applied in basic structure engineering, underwater structures, roads, etc., can solve the problem of affecting the stability and normal use of cantilever retaining walls, and cannot guarantee the overall stability of heightened structures. Problems such as external inclination and deformation of the vertical wall of the retaining wall are achieved to ensure stability and normal use, improve self-supporting capacity, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

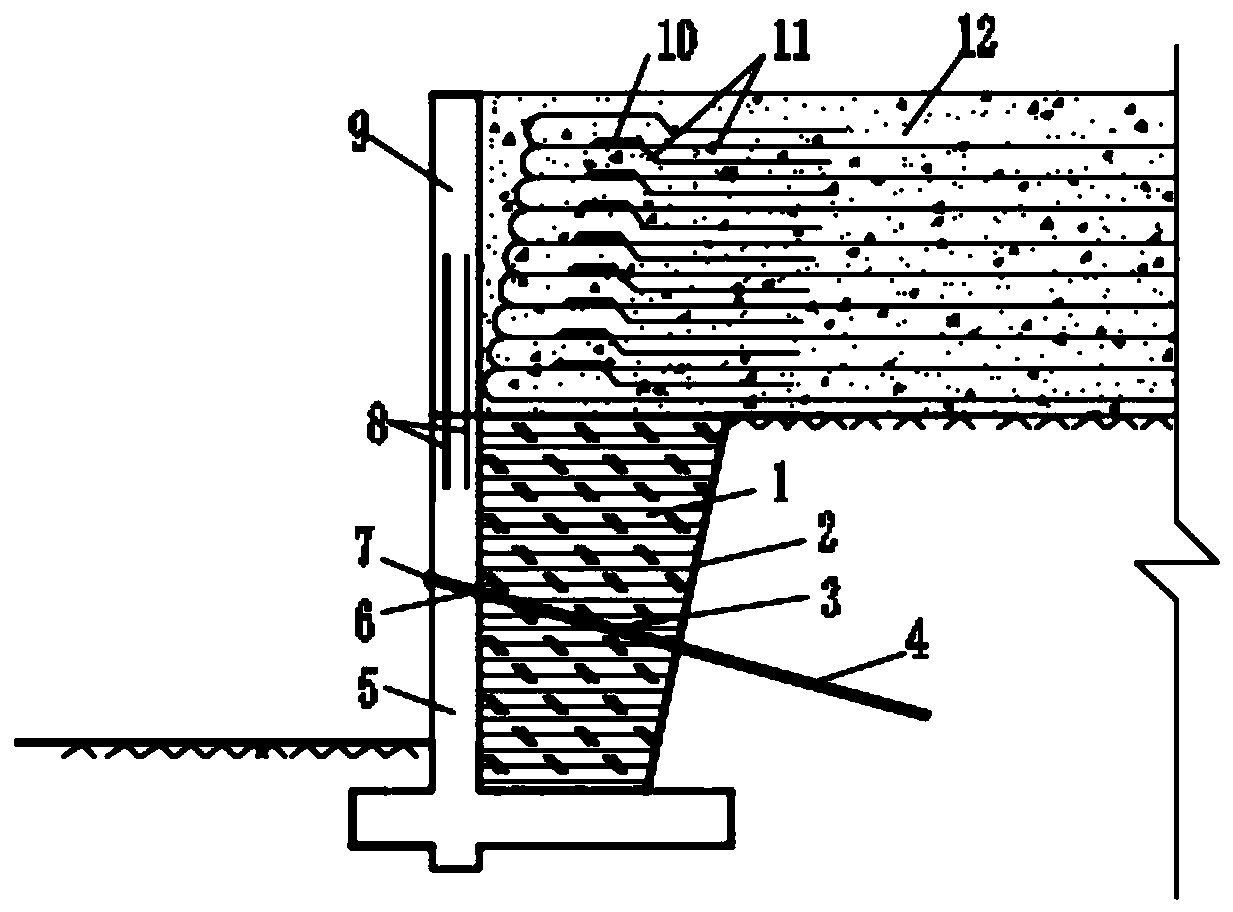

[0040] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-4 As shown, a retaining structure for raising rocky subgrades, including rocky subgrades, prestressed anchor cables, connecting rods 8, wall panels 9, connecting rods 10 and geogrids 11;

[0041] The rocky subgrade includes a cantilever retaining wall 5, miscellaneous fill 1 and rock slope 2, and the miscellaneous fill 1 is buried between the cantilever retaining wall 5 and the rock slope 2;

[0042] The prestressed anchor cables are arranged obliquely in the rocky subgrade.

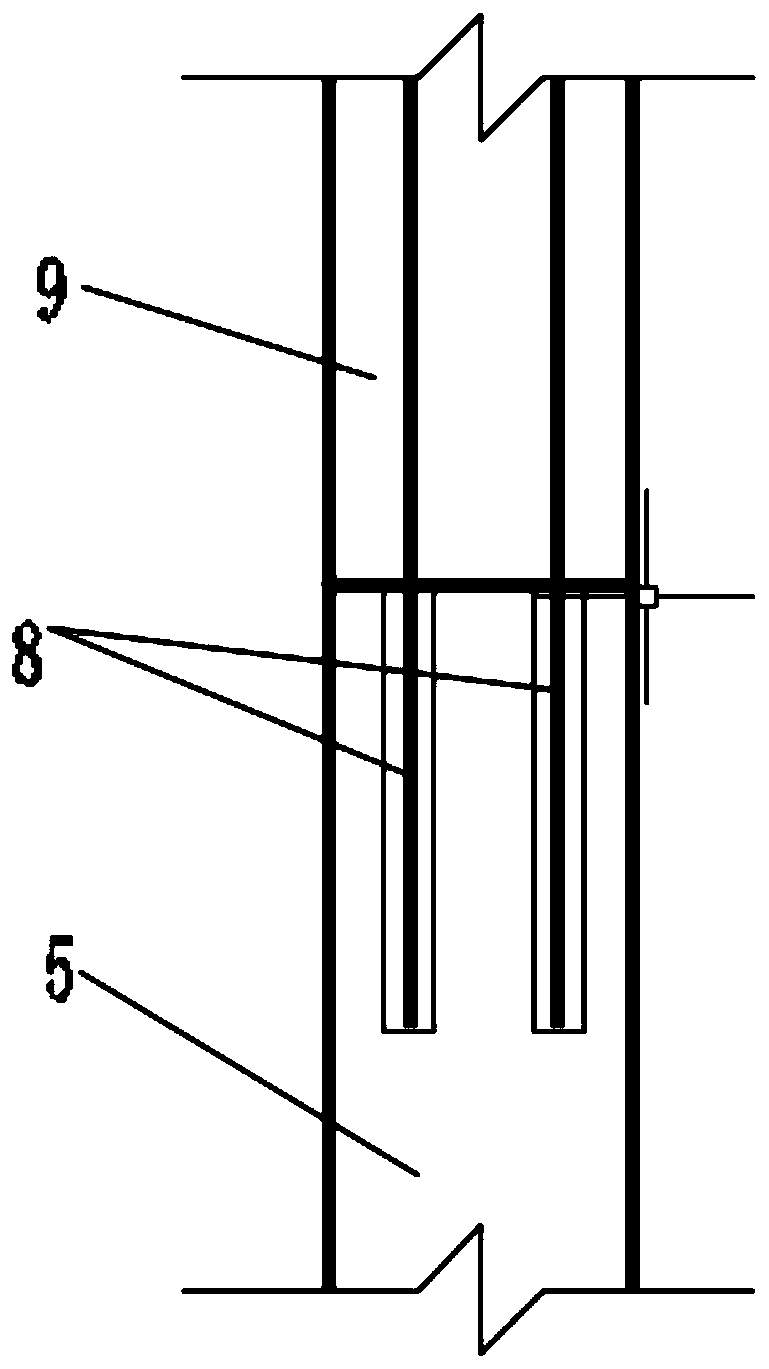

[0043] A wall panel 9 is arranged on the top of the cantilever retaining wall 5, and the wall panel 9 is connected with the cantilever retaining wall 5 through a connecting rod 8;

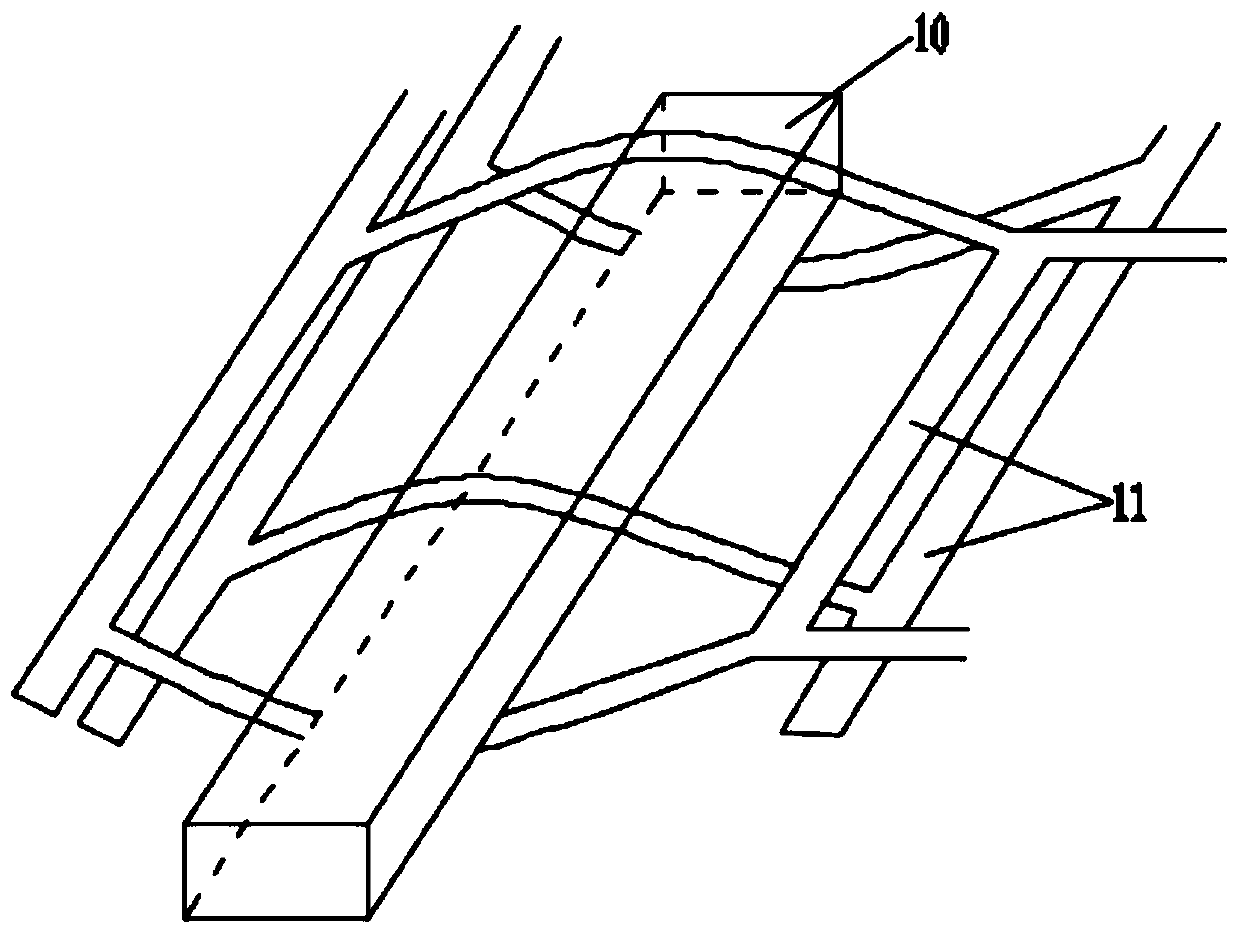

[0044] The rocky subgrade inside the wall panel 9 is provided with multi-layer geogrid 11 and filler 12 to form a raised subgrade.

[0045] Further, the prestressed anchor cable is composed of an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com