Insulation framework and motor stator

A technology of insulating skeleton and motor stator, which is applied to the shape/style/structure of winding insulation, electrical components, electromechanical devices, etc., and can solve problems such as limited layout of crimping terminal slots, small adjustment space for parts, and weak structural strength. Achieve the effects of eliminating the space for embedded wires, improving the insulation withstand voltage level, and improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

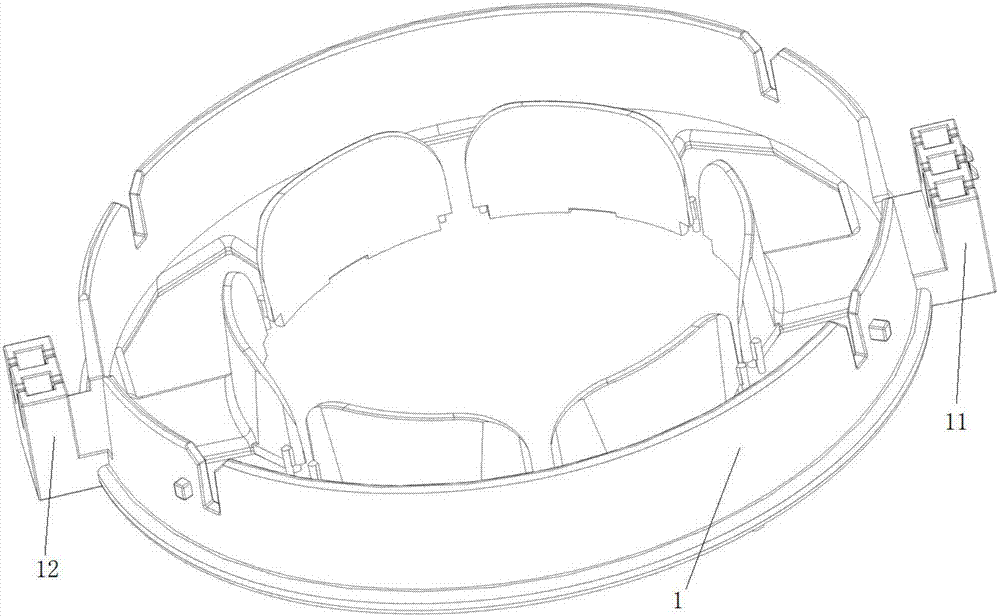

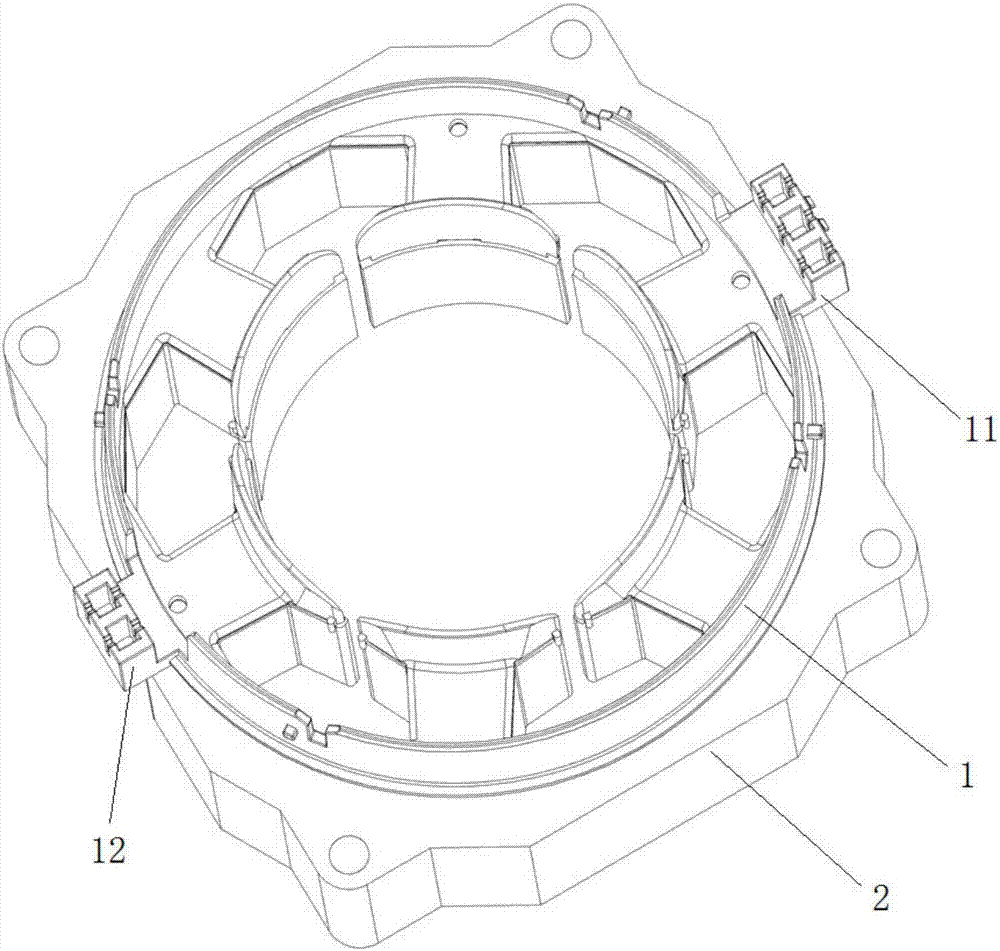

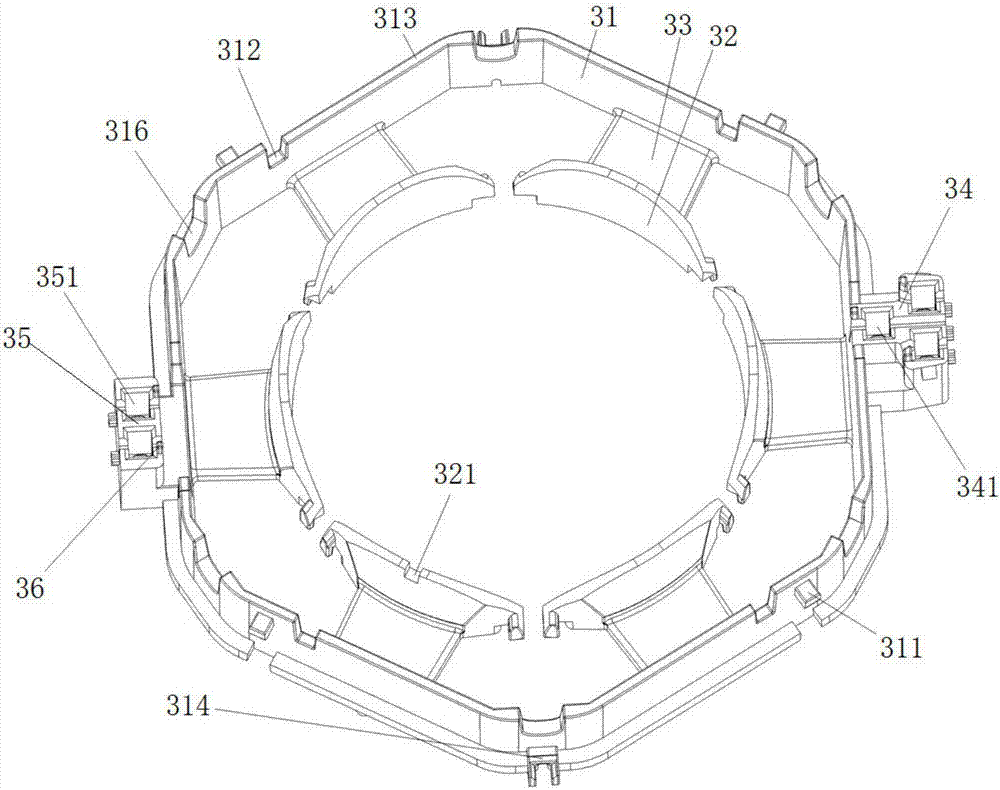

[0081] This embodiment provides an insulating frame used on a motor stator. Specifically, such as image 3 , Figure 6 , Figure 7 and Figure 10 As shown, the insulating frame in this embodiment includes an insulating frame body; wherein, the insulating frame body is provided with a three-phase lead wire terminal slot 34 for connecting the lead wire assembly. Wherein, three terminal slots 341 are provided on the three-phase lead wire terminal slot portion 34 , and each terminal slot 341 is used for installing crimping terminals. Wherein, the centers of the three terminal grooves 341 on the three-phase lead wire terminal groove portion are not on a straight line (that is, the centers of the three terminal grooves are respectively three vertices of a triangle. The " Center" is defined as follows: first, when the three terminal slots 341 are regular slots, the "center" of each terminal slot 341 is the centroid of the terminal slot, and at this time, the centroid of each term...

Embodiment 2

[0086] Preferably, this embodiment provides an insulating frame. Compared with the previous embodiment, this embodiment designs the insulating frame body as follows:

[0087] Such as Figure 3 to Figure 5 As shown, the insulating frame body in this embodiment includes a first annular wall 31 , a second annular wall 32 and a plurality of connecting pieces 33 for connecting the first annular wall 31 and the second annular wall 32 . Wherein, the second annular wall 32 is located inside the first annular wall 31 . One end of the connecting piece 33 is connected to the first annular wall 31 , and the other end is connected to the second annular wall 32 . Moreover, the connecting piece 33 is used as a winding portion of the insulating frame for winding the stator winding.

[0088] Preferably, the connecting piece 33 serves as the bottom plate of the insulating frame. The second annular wall 32 includes a plurality of second walls arranged at intervals; wherein, the number of the ...

Embodiment 3

[0091] Preferably, this embodiment provides an insulating skeleton, compared with the previous embodiment, such as image 3 , Figure 6 , Figure 7 to Figure 8 As shown, the present embodiment further designs the three-phase lead wire terminal slot 34 as follows:

[0092]As described in Embodiment 1, the three terminal slots 341 on the three-phase lead wire terminal slot portion 34 in this embodiment are respectively the first terminal slot, the second terminal slot and the third terminal slot. Wherein, the groove wall of the first terminal groove is connected with the first annular wall 31 . There is a gap between the second terminal slot, the third terminal slot and the first annular wall 31 , and the gap is used for passing wires so as to insert the winding wires into the second terminal slot and the third terminal slot. Wherein, the center of the first terminal groove is equivalent to the vertex of a triangle formed by connecting the centers of the three terminal groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com