Multifunctional high speed clarifier

A clarifier and multi-functional technology, which is applied in the field of sedimentation tank, clarification tank, grit chamber and air flotation tank, can solve the problems of high energy consumption of the clarifier impeller, long time of water retention in the tank, low water treatment rate, etc. Blockage of the aeration head, reduction of air flotation energy consumption, and enhanced separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

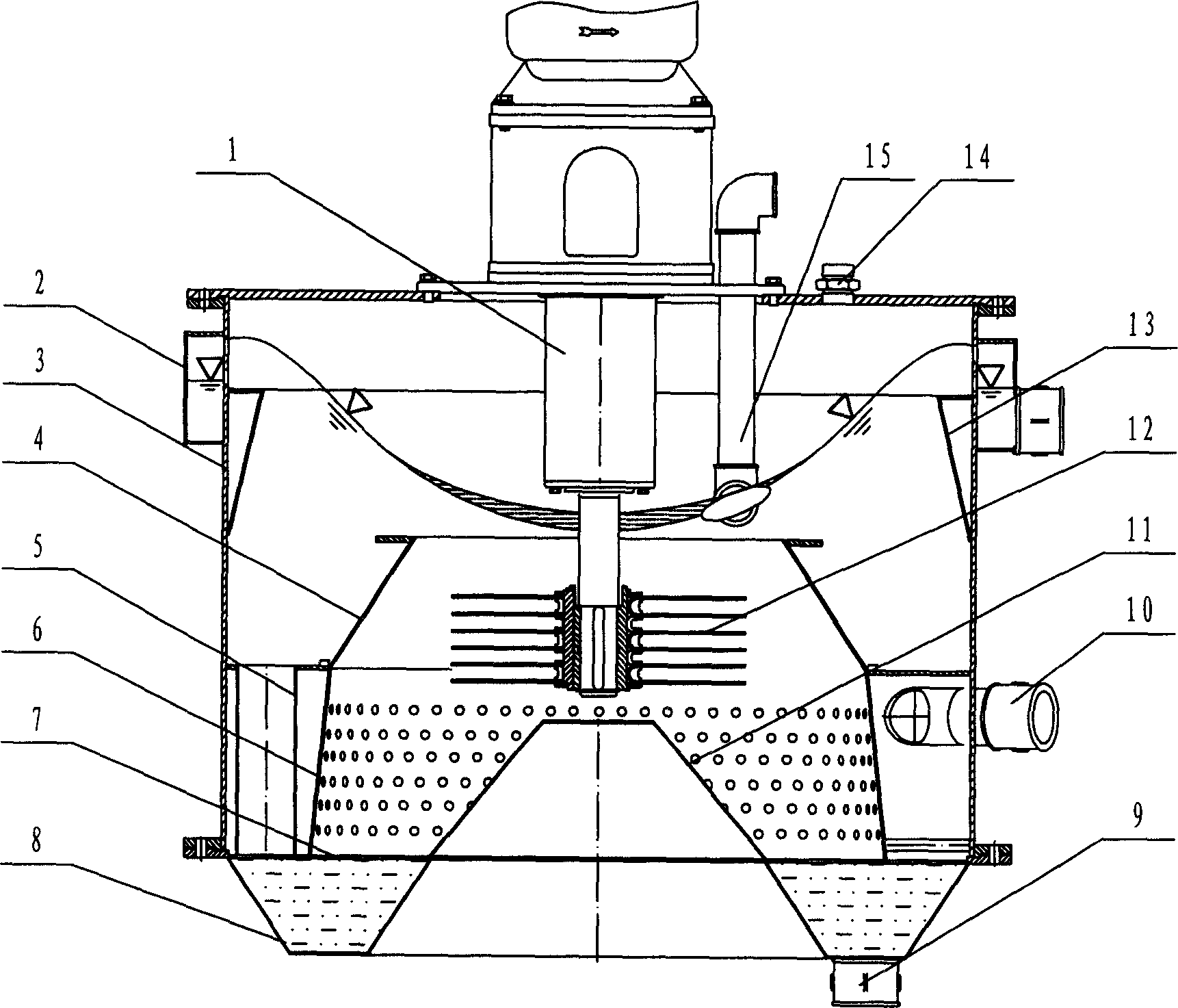

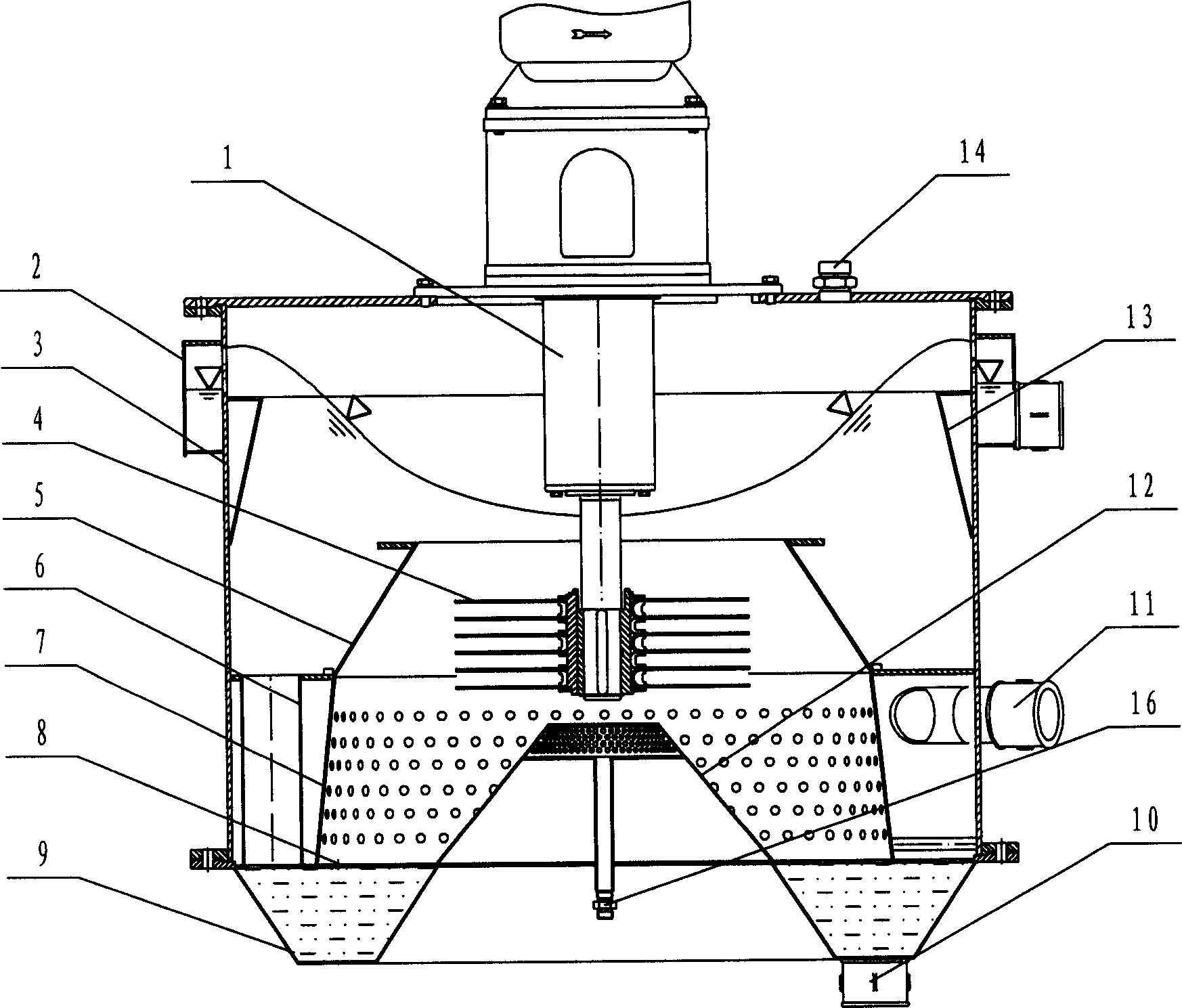

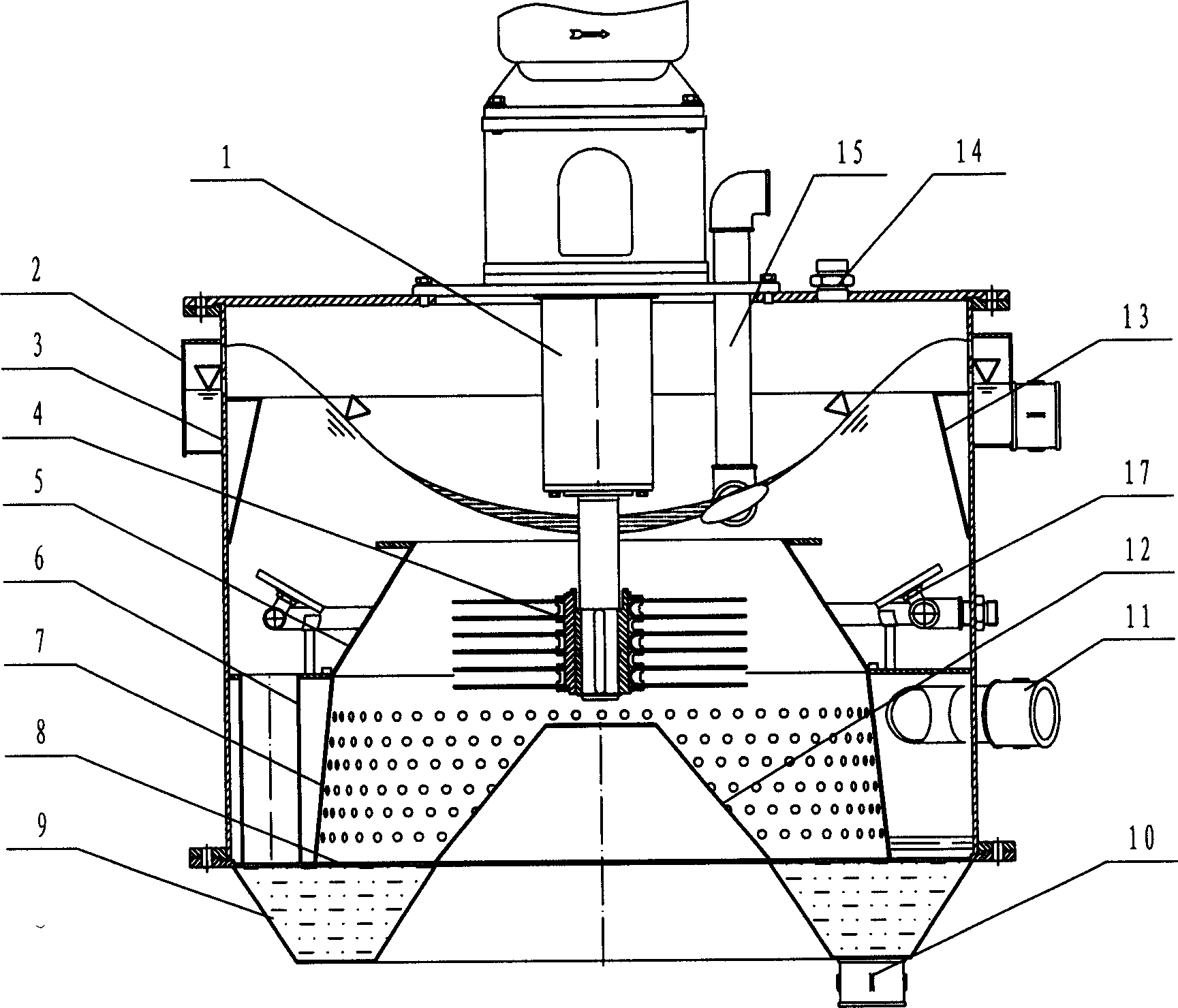

[0076] see figure 1 , which is a skimming precipitator designed according to the technical solution of the present invention. It contains a straight garden cylindrical warehouse 3, a set of transmission device 1, a set of pinwheel 4, thickening mud bucket 9, shielding plate 8, slurry feeding hydrodynamic separator 7, main separation cone 5, tertiary settling cone 13, Skimmer 15.

[0077] Cylindrical bin 3 is a garden tube, with flanges on the upper and lower ends, a slurry inlet pipe 11 connected eccentrically to the bottom, overflow tank 2 connected to the top, and thickening mud bucket 9 is connected with cylindrical bin 3 at the upper part of shielding plate 8. There is a conical frustum 12 in the upper part of the center of the shielding plate 8 . The garden ring separates the slurry inlet area from the hydrodynamic separator 7, and several settling feed pipes 6 are also connected on the garden ring. There are several pile tops between the hydrodynamic separator 7 or th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com