Automatic slag removal structure of biomass particle fireplace

A technology of biomass granules and automatic slag removal, applied in lighting and heating equipment, etc., can solve problems such as difficult promotion and application, unusable fireplaces, and large restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

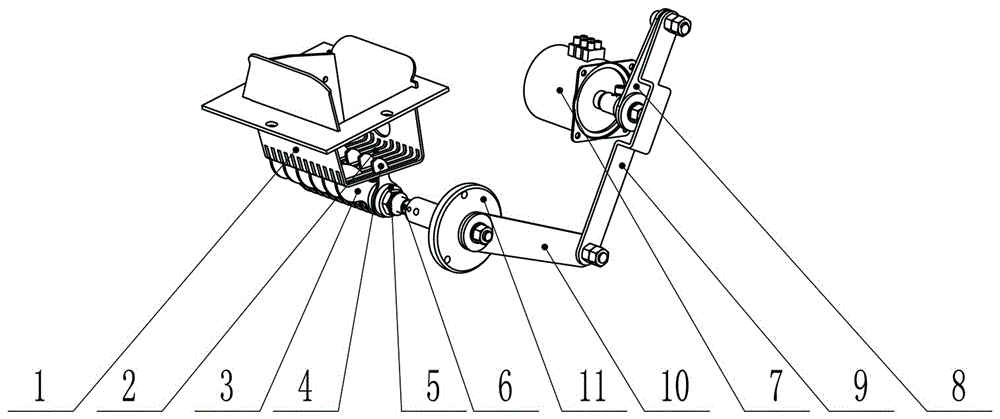

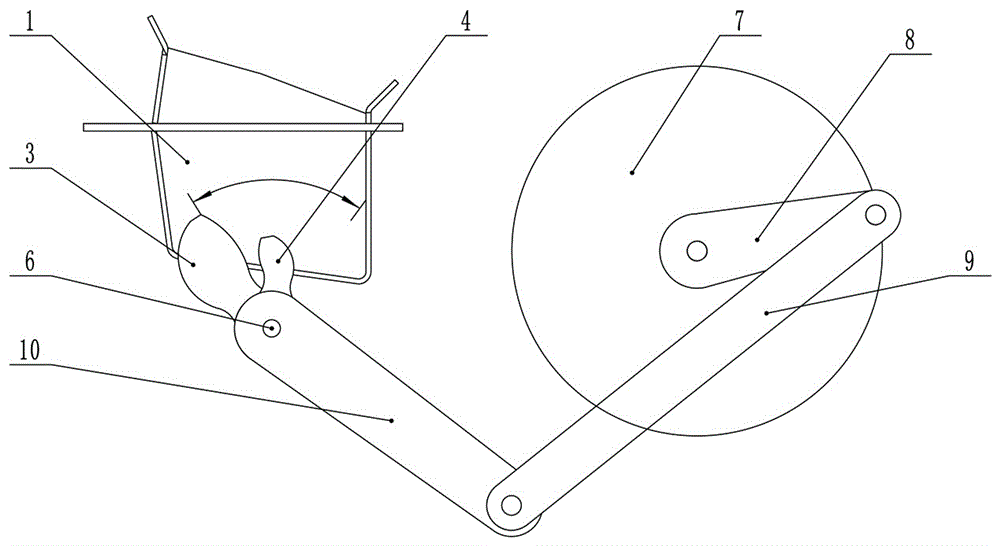

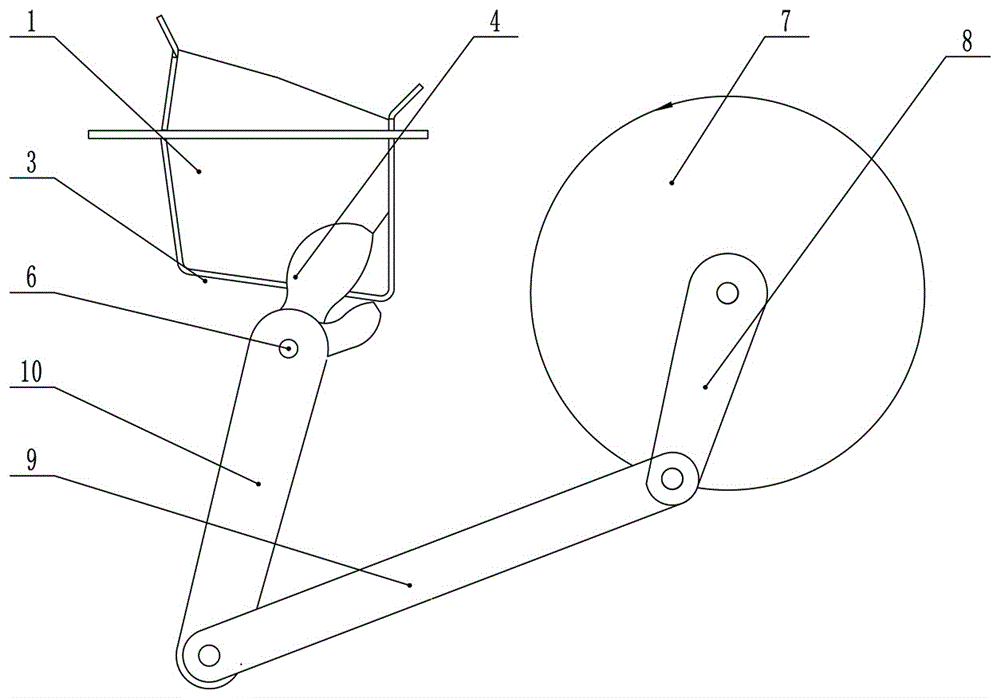

[0033] Such as figure 1 with Image 6 As shown, an automatic slag removal structure for a biomass pellet fireplace includes a combustion pool 1, a slag removal ventilation device and a power mechanism.

[0034] Wherein, the bottom of the combustion pool 1 is provided with multiple rows of slot-shaped ventilation holes 2 .

[0035] Such as Figure 2-4 , Figure 5-1 with Figure 5-2 As shown, the slag removal ventilation device includes a rotating shaft 6 and a slag removal tooth piece 3 and a ventilation tooth piece 4 installed on the rotation shaft 6 at intervals. A retaining ring 5 is set so that the slag removal tooth piece 3 and the ventilation tooth piece 5 are inserted into each of the slot-shaped ventilation holes 2 at intervals, and the slag removal tooth piece 3 extends into the interior of the combustion pool 1 so as to break the block The slag, like a knife blade, will forcefully crush the burning residue that is about to slag or has already slagged, and leaks d...

Embodiment 2

[0045] Such as Figure 7 As shown, an automatic slag removal structure for a biomass pellet fireplace includes a combustion pool 1, a slag removal ventilation device and a power mechanism, wherein the bottom of the combustion pool 1 is provided with multiple rows of slot-shaped ventilation holes 2; the slag removal ventilation The device includes a rotating shaft 6 and a slag removing gear 3 installed on the rotating shaft 6, and a retaining ring 5 is arranged between each of the slag removing gears 3 so that the slag removing gear 3 is respectively inserted into each of the grooves for ventilation. In the hole 2, the free end of the slag removal tooth piece 3 extends into the interior of the combustion pool 1 so as to break the slag; the power mechanism includes a deceleration motor (not shown in the figure) that drives the rotating shaft 6 to rotate. The deceleration motor is connected to the slag removal gear 3 through the rotating shaft 6, and drives the slag removal gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com