Cathode for secondary battery and secondary battery comprising same

A secondary battery and positive electrode technology, which is applied in the direction of secondary batteries, battery electrodes, electrode collector coatings, etc., can solve the problems of lower output characteristics, reduce the probability of conductive agent contact, etc., and achieve the effect of improving output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

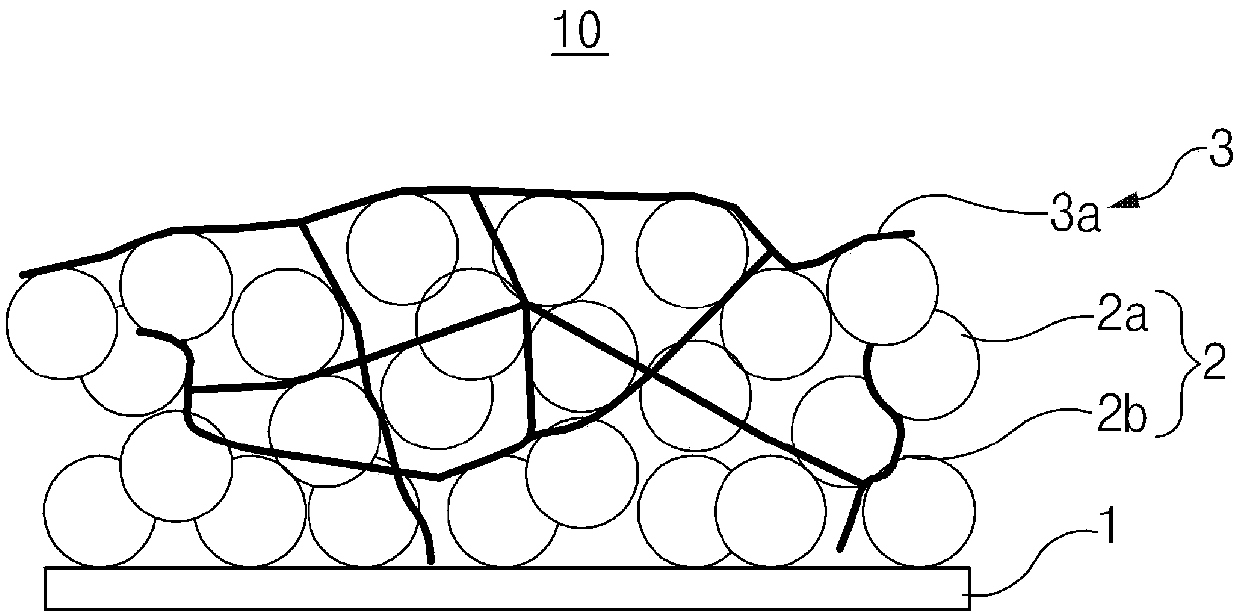

[0113] image 3 is a flowchart schematically showing a method of producing a positive electrode for a secondary battery according to an embodiment of the present invention. image 3 It is just an example for illustrating the present invention, and the present invention is not limited thereto. In the following, reference will be made to image 3 Each step is explained.

[0114] First, step 1 for preparing a positive electrode for a secondary battery is a step ( S1 ) of preparing a composition for forming a conductive layer.

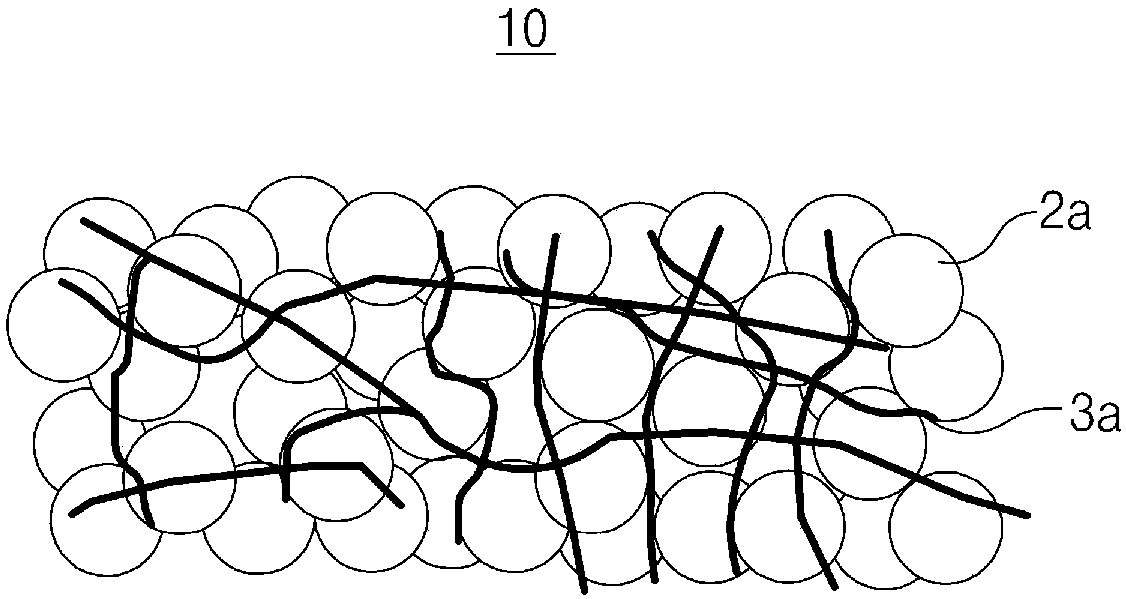

[0115] The composition for forming the conductive layer can be prepared by adding carbon nanotubes to the dispersion medium, wherein specifically, in order not to mix the carbon nanotubes in the dispersion medium, but to make the carbon nanotubes on the surface of the dispersion medium A three-dimensional porous network structure layer is formed on the conductive layer, the second carbon nanotubes are gradually dropped on the dispersion medium, and then th...

Embodiment 1

[0153] (Preparation of positive electrode active material)

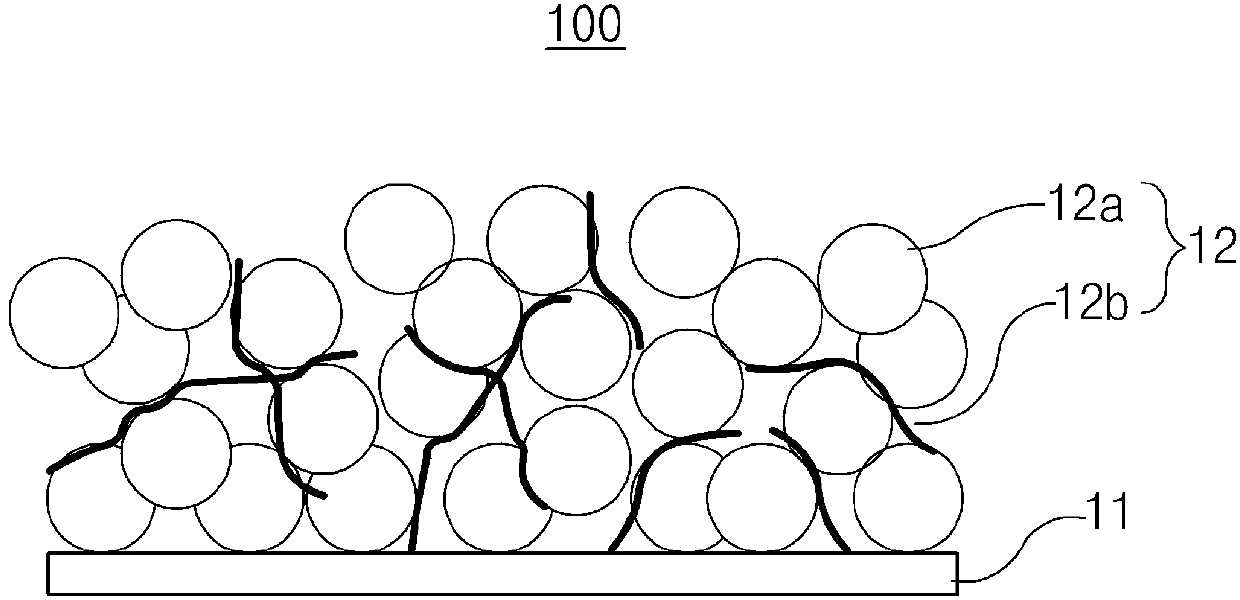

[0154] Will Li(Ni 0.6 mn 0.2 co 0.2 )O 2 Cathode active material (D 50 =11 μm), the first carbon nanotube (bundled carbon nanotube with the following specifications: monomer length: 3 μm, diameter: 10 nm, specific surface area: 300 m 2 / g, and bulk density: 0.13kg / m 3 ) and PVdF binder are mixed in N-methylpyrrolidone solvent in a weight ratio of 98.02:0.4:1.58 to prepare a composition for forming a positive electrode (viscosity: 5000mPa·s), and use the composition to collect aluminum Electric Appliance Coating was performed and dried at 130° C. to prepare a positive electrode assembly (porosity of the positive electrode active material layer: 30% by volume).

[0155] (Preparation of composition for forming conductive layer)

[0156] With 0.05g of the second carbon nanotubes (bundled carbon nanotubes with the following specifications: monomer length: 5 μm, diameter: 10nm, specific surface area: 300m 2 / g, and b...

Embodiment 2

[0160] In addition to using Li(Ni 0.6 mn 0.2 co 0.2 )O 2 Cathode active material (D 50 =11 μm), the first carbon nanotube (bundled carbon nanotube with the following specifications: monomer length: 3 μm, diameter: 10 nm, specific surface area: 300 m 2 / g, and bulk density: 0.13kg / m 3 ) and PVdF binder mixed in N-methylpyrrolidone solvent in a weight ratio of 98.26:0.2:1.54 except for the composition (viscosity: 5000mPa·s) for forming the positive electrode, the same as in Example 1 Positive electrode was prepared in the same way (the thickness ratio=1:0.002 of the positive electrode active material layer to the conductive layer, the porosity=30 volume % in the active material layer, the porosity=56 volume % of the conductive layer, and the first carbon nanotube: The weight ratio of the second carbon nanotubes = 1:0.34) (see Table 1 below).

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com