Prepreg and carbon-fiber-reinforced composite material

A prepreg, carbon fiber cloth technology, applied in the direction of carbon fiber, fiber processing, thin material processing, etc., can solve the problems of low reactivity, difficult to achieve high adhesion of matrix resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

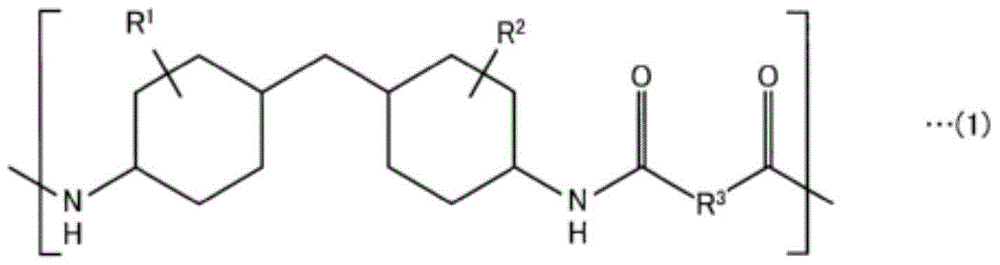

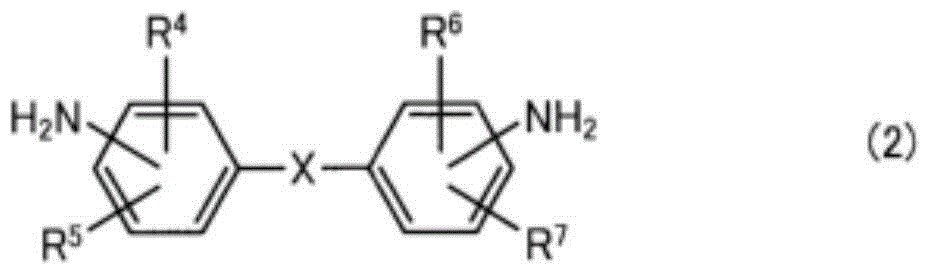

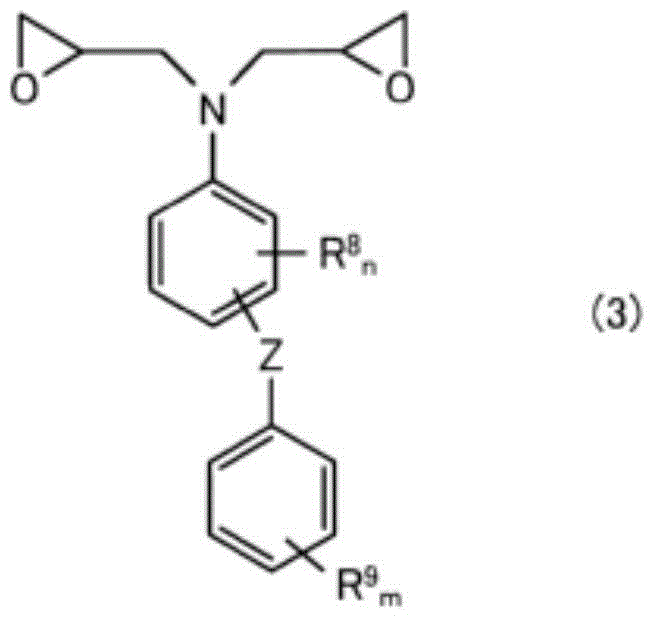

[0110] The prepreg according to Embodiment 1 of the present invention is characterized in that it is a prepreg prepared by impregnating a thermosetting resin composition into sizing-coated carbon fibers coated with a sizing agent, the sizing agent being at least Containing an aliphatic epoxy compound (A) and an aromatic epoxy compound (B1) as an aromatic compound (B), for the sizing agent coated carbon fiber, by X-ray photoelectron spectroscopy at a photoelectron take-off angle of 15° C measured on the surface of the sizing agent applied to the carbon fiber 1s In the core level energy spectrum (a) the height (cps) of the components assigned to the bond energy of CHx, C-C, and C=C (284.6eV) and (b) the bond energy assigned to C-O (286.1eV) The ratio (a) / (b) of the height (cps) of the components is 0.50 to 0.90, and the thermosetting resin composition is an epoxy resin composition comprising at least the following constituent elements, the constituent elements being (D): Epoxy ...

Embodiment approach 2

[0353] The prepreg according to Embodiment 2 of the present invention is characterized in that it is a prepreg prepared by impregnating a thermosetting resin composition into sizing agent-coated carbon fibers coated with a sizing agent containing The aliphatic epoxy compound (A) and the aromatic compound (B) contain at least an aromatic epoxy compound (B1), and the carbon fiber is coated with the sizing agent by using AlKα 1,2 As the X-ray photoelectron spectroscopy of the X-ray source, the C of the sizing agent surface coated on the carbon fiber is measured with a photoelectron take-off angle of 15° 1sIn the core level energy spectrum (a) the height (cps) of the components assigned to the bond energy of CHx, C-C, and C=C (284.6eV) and (b) the bond energy assigned to C-O (286.1eV) The ratio (a) / (b) of the height (cps) of the components is 0.50 to 0.90, and the thermosetting resin composition includes at least epoxy resin (D1), latent curing agent (E), and has the following gen...

Embodiment approach 3

[0479] The prepreg according to Embodiment 3 of the present invention is characterized in that it is a prepreg prepared by impregnating an epoxy resin composition into sizing-coated carbon fibers coated with a sizing agent, the sizing agent Containing an aliphatic epoxy compound (A) and at least an aromatic epoxy compound (B1) as an aromatic compound (B), for the sizing agent coated carbon fiber, by using AlKα 1,2 As the X-ray photoelectron spectroscopy of the X-ray source, the C measured on the surface of the sizing agent coated on the carbon fiber with a photoelectron take-off angle of 15° 1s In the core level energy spectrum (a) the height (cps) of the components assigned to the bond energy of CHx, C-C, and C=C (284.6eV) and (b) the bond energy assigned to C-O (286.1eV) The ratio (a) / (b) of the height (cps) of the components is 0.50 to 0.90, and the epoxy resin composition contains at least epoxy resin (D1) and latent curing agent (E) by the following An epoxy resin compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com