Cementing materials for filling, slurry and preparing and filling processes

A gelling material, paste-like technology, applied in the field of cemented filling, can solve the problems of high paste filling concentration, affecting production stability and safety, difficulty in paste slurry transportation, etc., and achieve good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

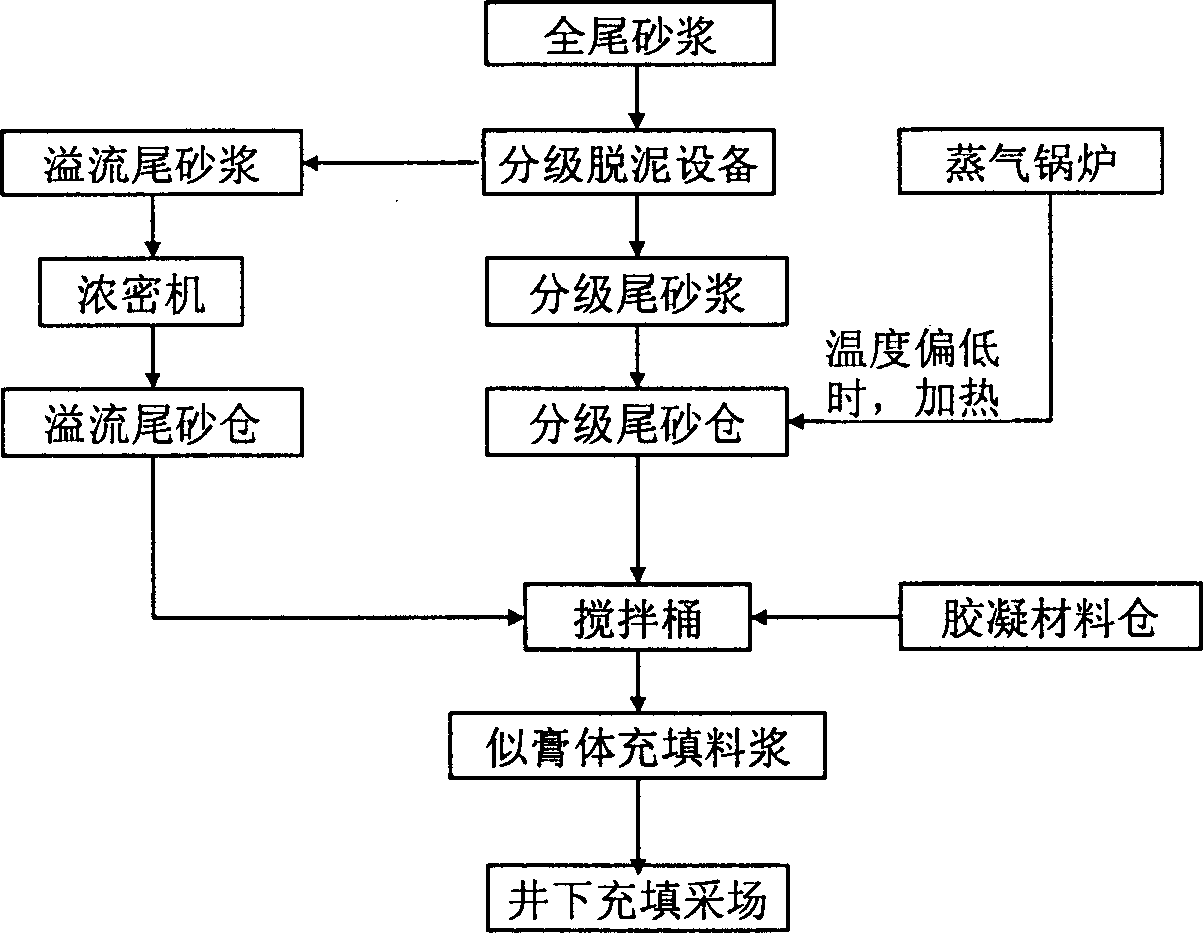

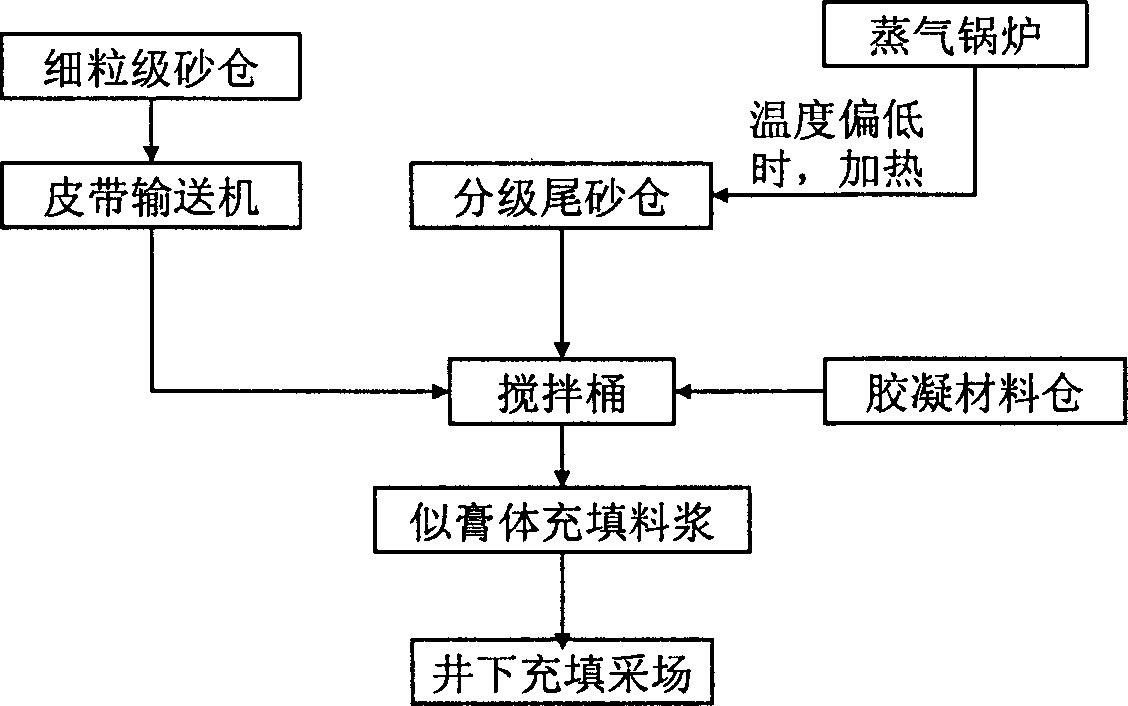

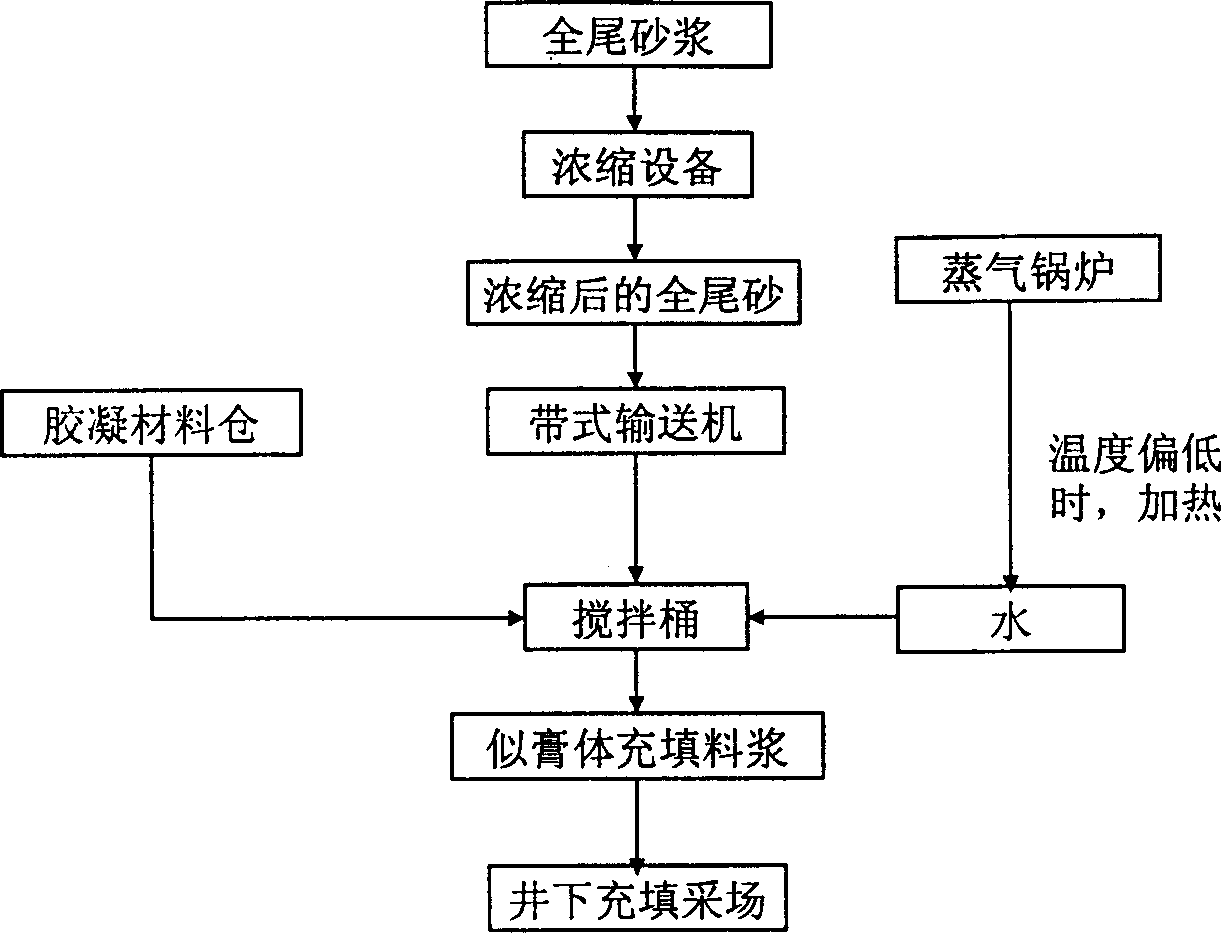

Method used

Image

Examples

Embodiment 1

[0130] (1) The distribution ratio of each component of the gelling material used for paste filling

[0131] Component A (water-quenched iron-making blast furnace slag 50% and water-quenched ferromanganese blast furnace slag 30%) 80%

[0132] Component B (fluorogypsum 6% and dihydrate gypsum 4%) 10%

[0133] Component C (lime) 9%

[0134] Component F (sodium hydroxide 0.7%, lithium carbonate 0.01% and tartaric acid 0.29%) 1%

[0135] Using a process similar to the production of cement, A, B, C, and F are made into a specific surface area of 3800 cm by batching, grinding, and homogenization according to the above ratio. 2 / g of the gelling material for later use.

[0136] (2) The ratio of paste-like gelling filling slurry and the compressive strength of paste-like filling are shown in Table 4

[0137] The compressive strength of paste-like cemented filling slurry with a weight concentration of 78% is prepared by using graded tailings and overflow tailings as aggregates and...

Embodiment 2

[0140] (1) The distribution ratio of each component of the gelling material used for paste filling

[0141] Component A (water-quenched iron-making blast furnace slag 40% and water-quenched phosphorus slag 25%) 65%

[0142] Component B (dihydrate gypsum 4% and anhydrite 3%) 7%

[0143] Component C (lime 7% and steel slag 5%) 12%

[0144] Component D (fly ash 10% and boiling slag 5%) 15%

[0145] Component F (sodium carbonate 0.8%, lithium hydroxide 0.01% and citric acid 0.19%) 1%

[0146] Using a process similar to the production of cement, A, B, C, D, and F are made into a specific surface area of 4000 cm by batching, grinding, and homogenization according to the above ratio. 2 / g of the gelling material for later use.

[0147] (2) The ratio of paste-like cemented filling slurry and the compressive strength of paste-like filling

[0148] Use river sand, silt and cementitious materials for filling like paste to prepare a slurry with a weight concentration of 80%.

[01...

Embodiment 3

[0151] (1) The distribution ratio of each component of the gelling material used for paste filling

[0152] Component A (water-quenched iron blast furnace slag) 35%

[0153] Component B (dihydrate gypsum) 10%

[0154] Component C (lime 5% and steel slag 15%) 20%

[0155] Component D (silica fume 1% and boiling slag 14%) 15%

[0156] Component E (limestone powder 8% and coal gangue powder 10%) 18%

[0157] Component F (sodium carbonate 1.5%, potassium sulfate 0.3%, borax 0.2%) 2%

[0158] Using a process similar to the production of cement, A, B, C, D, E, F are made into a specific surface area of 4500cm through batching, grinding and homogenization according to the above ratio. 2 / g of the gelling material for later use.

[0159] (2) The ratio of paste-like cemented filling slurry and the compressive strength of paste-like filling

[0160] The slurry with a weight concentration of 80% was prepared with river sand, silt and cementitious materials for filling like paste....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com