Manufacturing technique of crease-shedding uniforms lining

A production process and technology for suits, applied in the field of production technology of anti-wrinkle suit linings, can solve the problems of fabric creases or wrinkles, unable to meet the requirements of no-iron, affecting the appearance and neatness of clothing, etc., and achieves softness and excellent wrinkle resistance. , the effect of plump feel

Inactive Publication Date: 2008-10-22

严华荣

View PDF0 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After the suit lining is bonded to the non-ironing fabric, when the fabric is folded or washed, the bonded fabric will produce creases or wrinkles, which will affect the appearance and cleanliness of the garment, and it must be ironed to restore Flat or crisp appearance, can not meet the requirements of non-ironing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

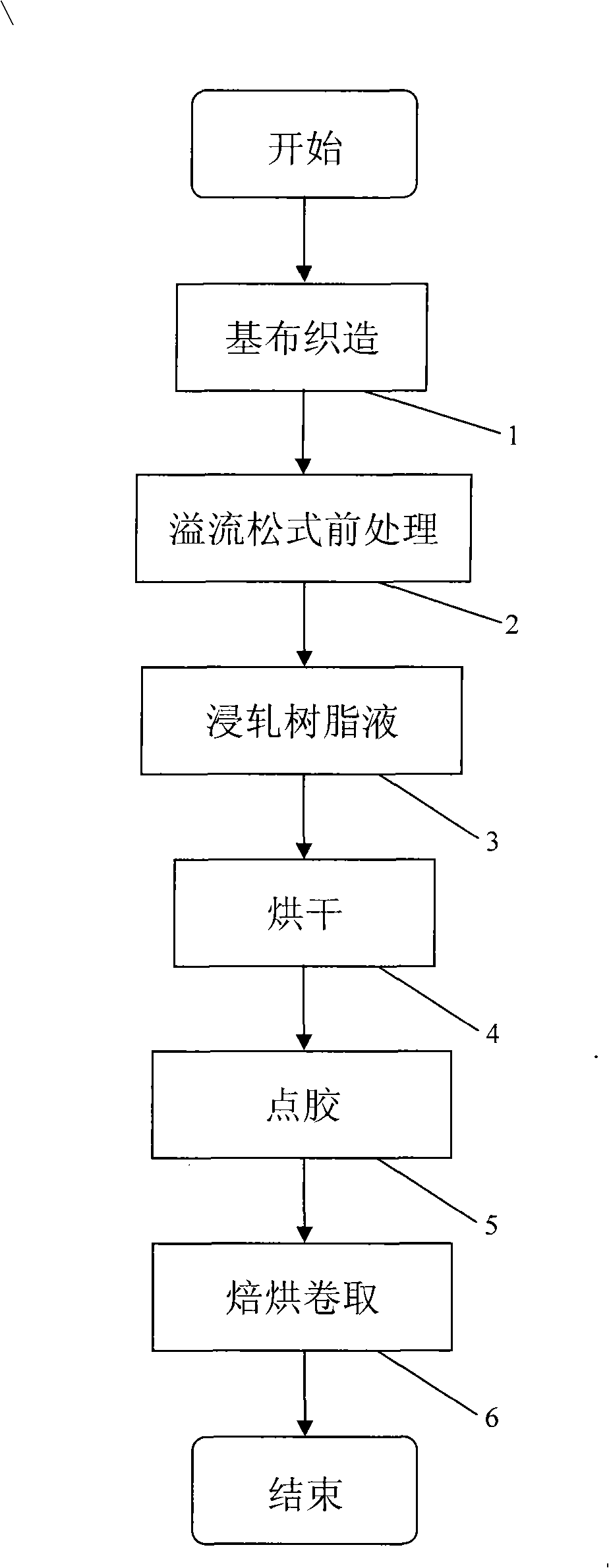

The invention discloses a technique for manufacturing anti-wrinkle liner of suits. The technique comprises the processes of weaving base fabric, overflow and loose pre-treatment, immersing in resin liquid and rolling, drying, gluing, baking, coiling and so on. The technique adopts environment-friendly resin liquid with high quality for twice-immersing and twice-rolling treatment which causes the resin liquid to sufficiently permeate into fibers and to become uniformly cross-linking, leads the treated fabric to obtain good anti-wrinkle recoverability and solid hand feeling. Nylon polyamine hotmelt adhesive is used for double-dot coating, which is characterized by strong adhesion fastness, having good drapability after being bonded with the fabric and excellent anti-wrinkle property when in use. The lining cloth has soft hand feeling and good anti-wrinkle property. Suits made from the lining cloth have the advantages of fullness and being docile. The anti-wrinkle property and sizing property after washing are better than any other ordinary adhesive lining cloth. The lining cloth is mainly used for wash-and-wear suits and career wears.

Description

A kind of production process of anti-wrinkle suit lining 【Technical field】 The invention relates to a weaving technology, more specifically, a production process of an anti-wrinkle suit lining. 【Background technique】 The current suit lining products are all made of polyester fiber as raw material for base fabric weaving. After overflow pre-treatment and shaping finishing, the base fabric is then double-point coated with polyamide hot-melt adhesive. After the suit lining is bonded to the non-ironing fabric, when the fabric is folded or washed, the bonded fabric will produce creases or wrinkles, which will affect the appearance and cleanliness of the garment, and it must be ironed to restore Flat or crisp appearance, can not meet the requirements of non-ironing. 【Content of invention】 The object of the present invention is to solve the problems in the prior art, and to propose a production process for an anti-wrinkle suit lining, which can make the suit interlining feel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A41D27/02D06N3/00D06M15/423D06M13/165D06M101/06D06M101/32

Inventor 韦毓堃严惠莲孙慧

Owner 严华荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com