Viloft shengma smooth edge denim and production technology thereof

A technology of denim and craftsmanship, applied in fabrics, textiles, textiles and papermaking, etc., can solve problems such as hidden dangers, uncontrollable quality of technical products, etc., and achieve good moisture absorption, softness, strong sense of mercerization, and excellent quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

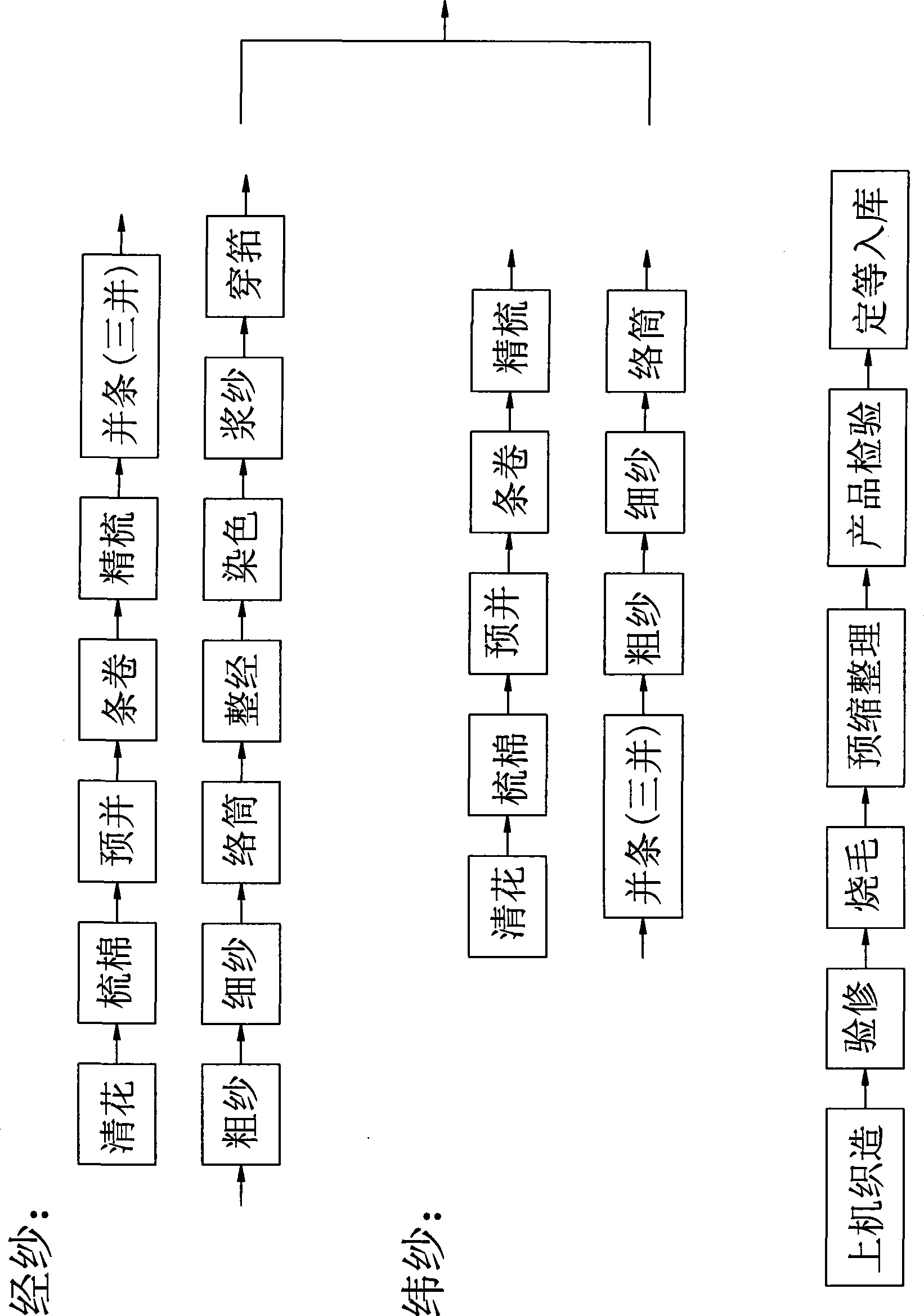

Method used

Image

Examples

Embodiment 1

[0052] The percentage by weight of each component in the denim is:

[0053] Veloft Fiber 50%;

[0054] Holy Hemp Fiber 50%.

[0055] Woven into (11+7)X(16+40D)X82X6031", soft and comfortable.

Embodiment 2

[0057]The percentage by weight of each component in the denim is:

[0058] Veloft Fiber 70%;

[0059] Holy Hemp Fiber 30%.

[0060] The present embodiment keeps warm, antibacterial.

Embodiment 3

[0062] The percentage by weight of each component in the denim is:

[0063] Veloft Fiber 20%;

[0064] Holy Hemp Fiber 80%.

[0065] The present embodiment is crisp and antibacterial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com