Preparation method of nano-silica spheres

A technology of nano-silica and silica spheres, applied in the field of nano-materials, can solve the problems of high cost and long preparation time, and achieve the effects of simple method, short preparation time and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

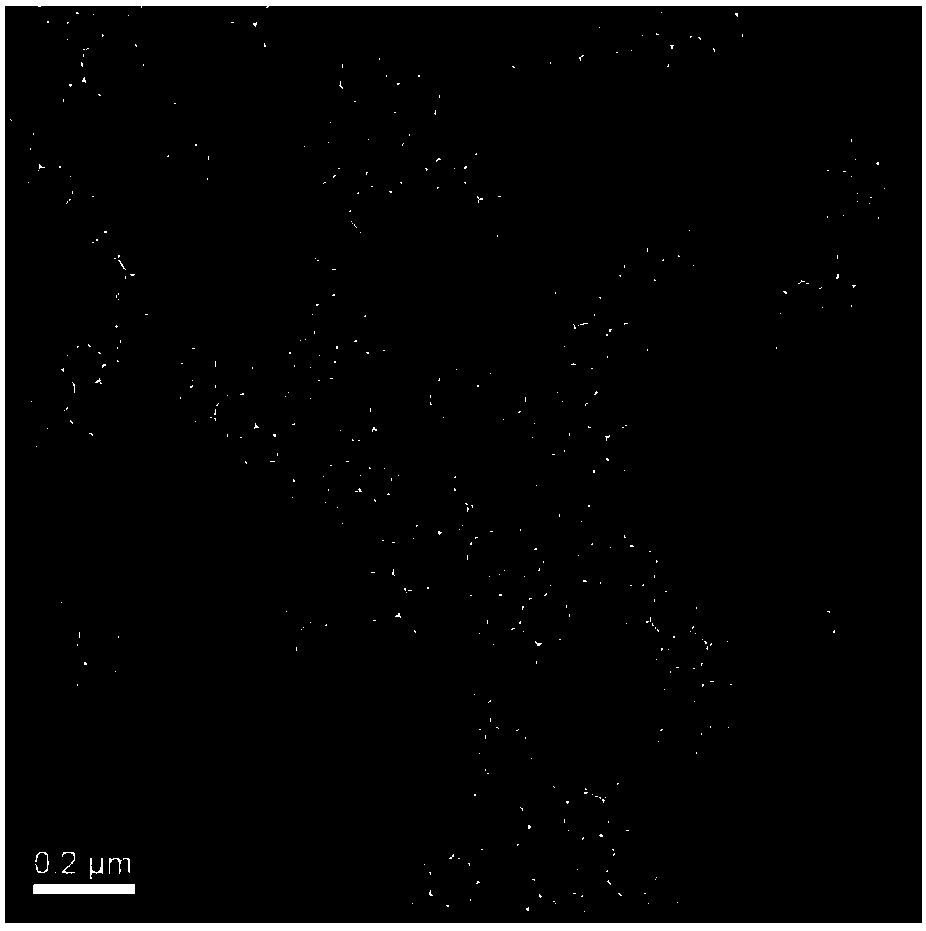

Image

Examples

Embodiment 1

[0038] The specific operation steps are as follows:

[0039] (1) Preparation of precursor solution: Mix ethanol and water at a mass ratio of 7:3 to obtain an ethanol solution with a mass fraction of 70%; then add 500 μL tetraethyl orthosilicate (TEOS) to 80 mL of ethanol solution, mix Evenly, the precursor solution was obtained.

[0040] (2) Preparation of nano-silica sphere suspension: put 80mL of the precursor solution in a high-shear mixer for stirring, add 5mL of ammonia water, and stir in a water bath at 30°C at a speed of 10000r / min. After stirring for 5min, you can see Until the appearance of nano-silica, after stirring for 15 minutes, the reaction is completed, and a suspension of nano-silica spheres is obtained. The nano-silica sphere suspension contains nano-silica spheres.

[0041] (3) Separation of nano-silica spheres: Centrifuge and wash the nano-silica sphere suspension with ethanol solution once at a speed of 6000r / min, then place the precipitate in a blast dr...

Embodiment 2

[0044] The specific operation steps of embodiment 2 are the same as embodiment 1, except that, in the step (2) of embodiment 2, the rotating speed of the high shear mixer is 13000r / min.

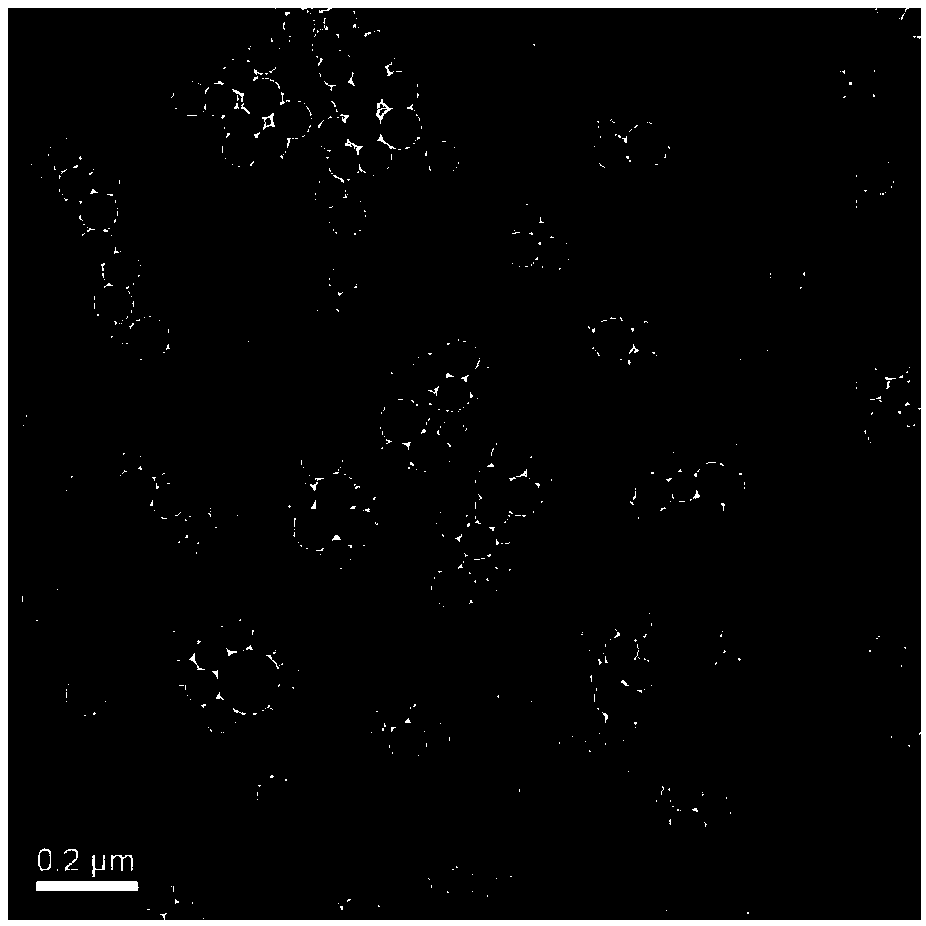

[0045] figure 2 Nano-SiO prepared for Example 1 of the present invention 2 The TEM image of the ball shows that the sample is spherical and normally distributed.

Embodiment 3

[0047] The specific operation steps of embodiment 3 are the same as embodiment 1, the difference is that in the step (2) of embodiment 3, the rotating speed of the high shear mixer is 16000r / min.

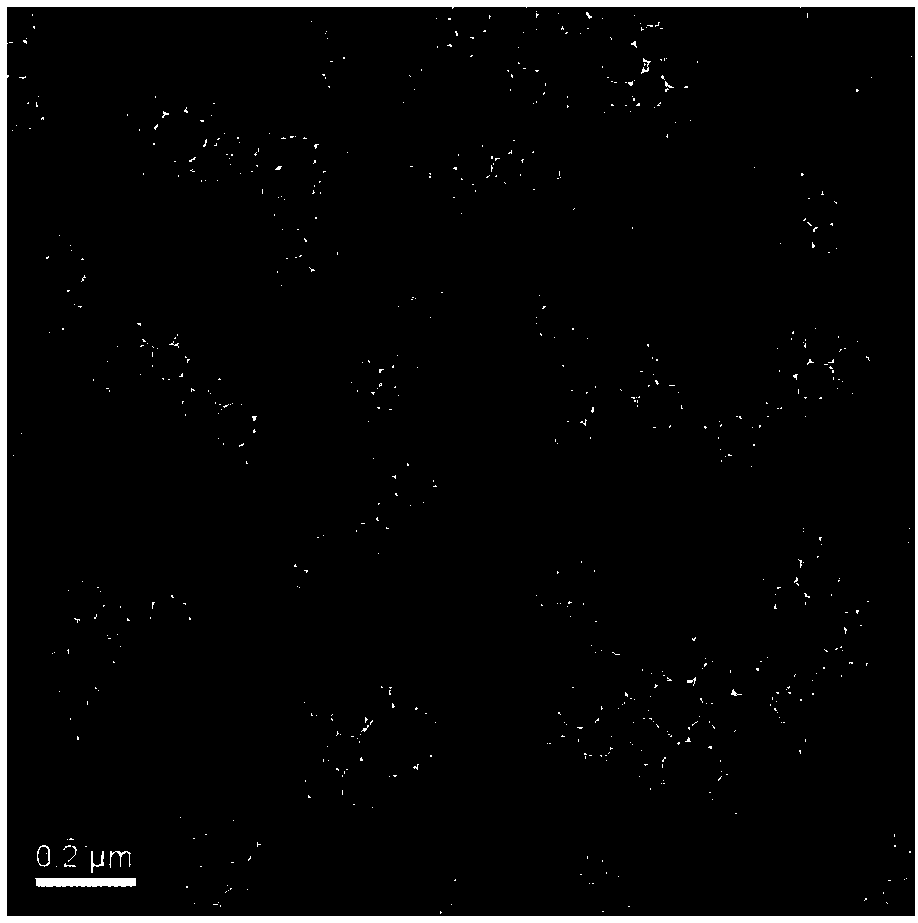

[0048] image 3 Nano-SiO prepared for Example 1 of the present invention 2 The TEM image of the ball shows that the sample is spherical and normally distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com