A kind of high-efficiency environment-friendly flame retardant for coating flame retardant and preparation method thereof

An intumescent flame retardant and coating technology, applied in the field of flame retardant coatings and new environmentally friendly flame retardants, can solve the problems of water resistance, low humidity and heat resistance, and achieve good flame retardant effect and good synergistic flame retardant effect. , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

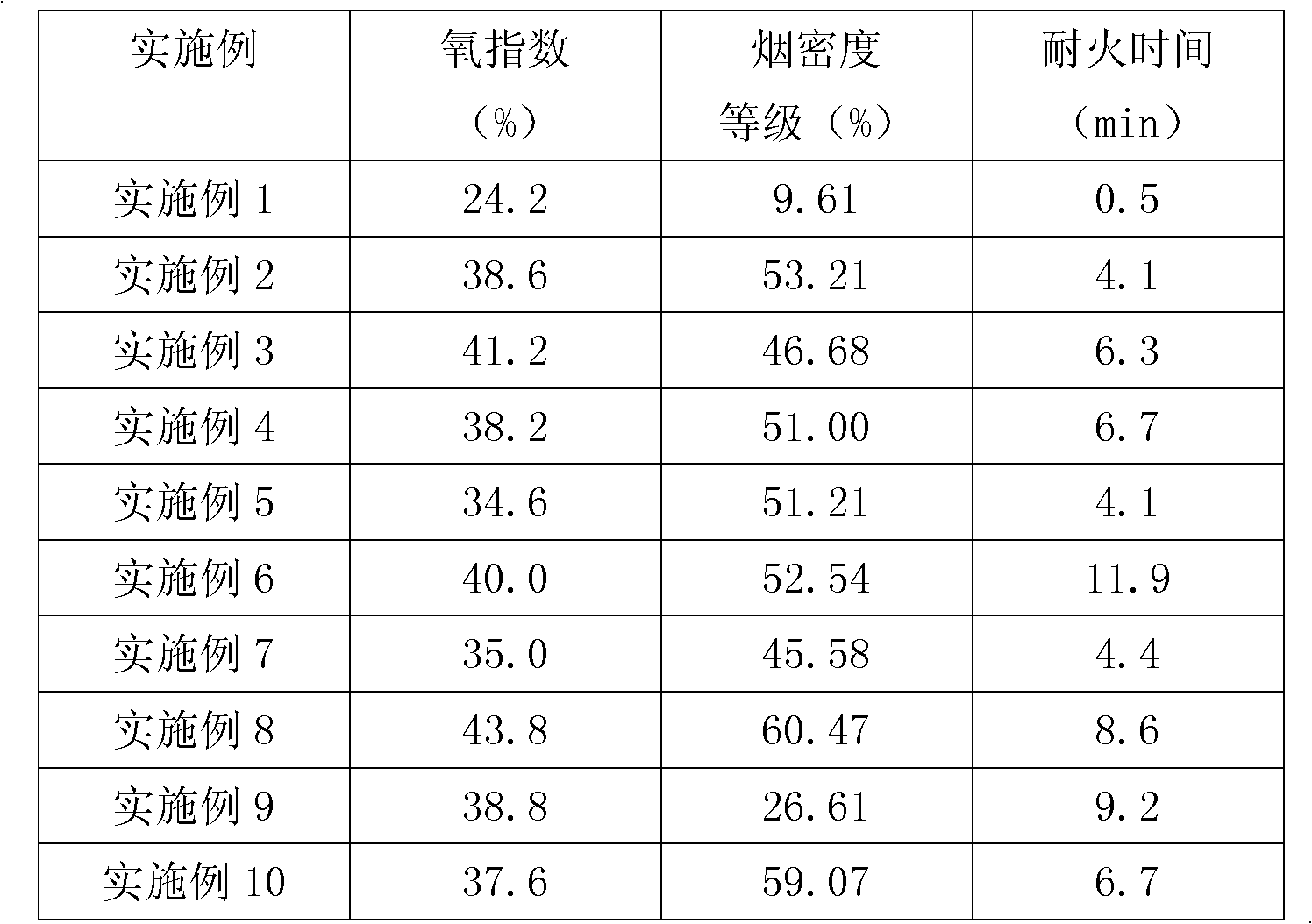

Examples

Embodiment 1

[0022] Embodiment 1 (comparative example)

[0023] Add 1.5 g of silane coupling agent grade 2.0 g of organically modified bentonite to 100 g of alkyd resin under mechanical stirring, and mix evenly at a high shear rate to obtain an alkyd resin coating.

Embodiment 2

[0024] Embodiment 2 (melamine comparative example)

[0025] Compound 42g of ammonium polyphosphate, 25g of pentaerythritol, and 5g of melamine to form a new flame retardant. After grinding for 1-2 hours, mix well, add to 100g of alkyd varnish, stir for 0.5-1h, add 2.1g of silane coupling agent grade 2.8 g Organically modified bentonite, mixed evenly at a high shear rate, can obtain intumescent flame-retardant coatings.

Embodiment 3

[0027] Compound 27g of ammonium polyphosphate, 12g of pentaerythritol, and 9g of tea saponin to form a new flame retardant, grind for 1-2 hours, mix well, add to 100g of alkyd varnish, stir for 0.5-1h, add 2.1g of silane coupling agent Grade 2.8g organically modified bentonite, mixed evenly at high shear rate, can get a new type of intumescent flame retardant coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com