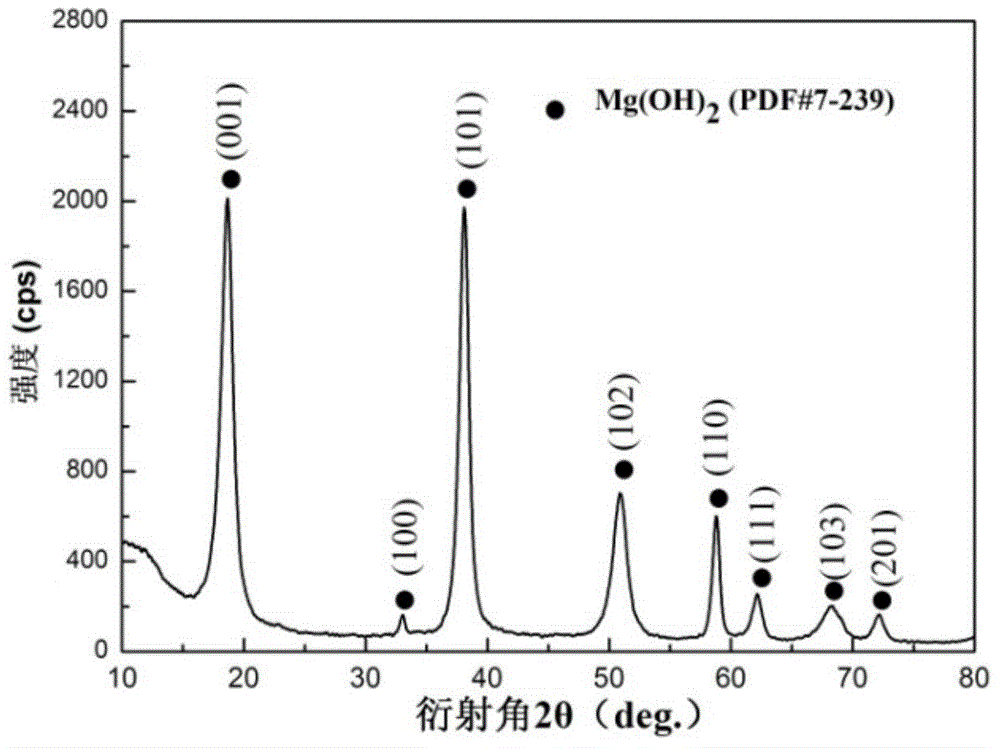

Preparation method of nano magnesium hydroxide material

A nano-magnesium hydroxide and magnesium salt technology, applied in the direction of magnesium hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of corrosion of reaction equipment, high equipment cost, and harsh requirements for equipment and equipment, and achieve low corrosion and low equipment requirements. Simple, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

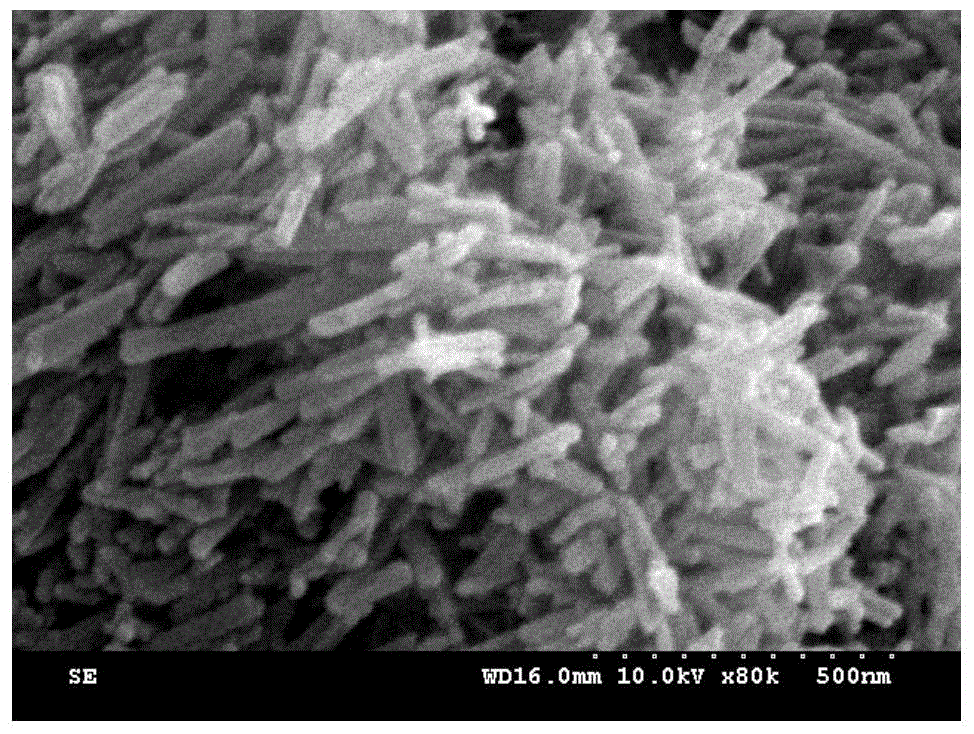

Embodiment 1

[0029] Step 1, preparing the precursor solution;

[0030] Weigh 250g of magnesium chloride and 50g of Tween 80, and add 1000mL of deionized water. After the mixture was fully stirred for 0.5 hours in a pipeline type high-shear mixer, a well-dispersed transparent solution was obtained as a precursor solution.

[0031] Step 2, preparing the precursor;

[0032] Add 7.5g of phosphoric acid to the precursor solution, and feed in ammonia gas at a flow rate of 5L / h; the reaction temperature is 100°C, and the high-shear mixer is used to stir at a speed of 10,000rpm. After 2 hours of reaction, filter to obtain the precursor .

[0033] Step 3, drying the precursor obtained in step 2 at 120° C. for 5 hours in a forced air drying oven, and the obtained white powder product is a nano-magnesium hydroxide material. If the temperature of the drying oven is too low, the drying time will be longer; if the temperature of the drying oven is too high, magnesium hydroxide will be decomposed into...

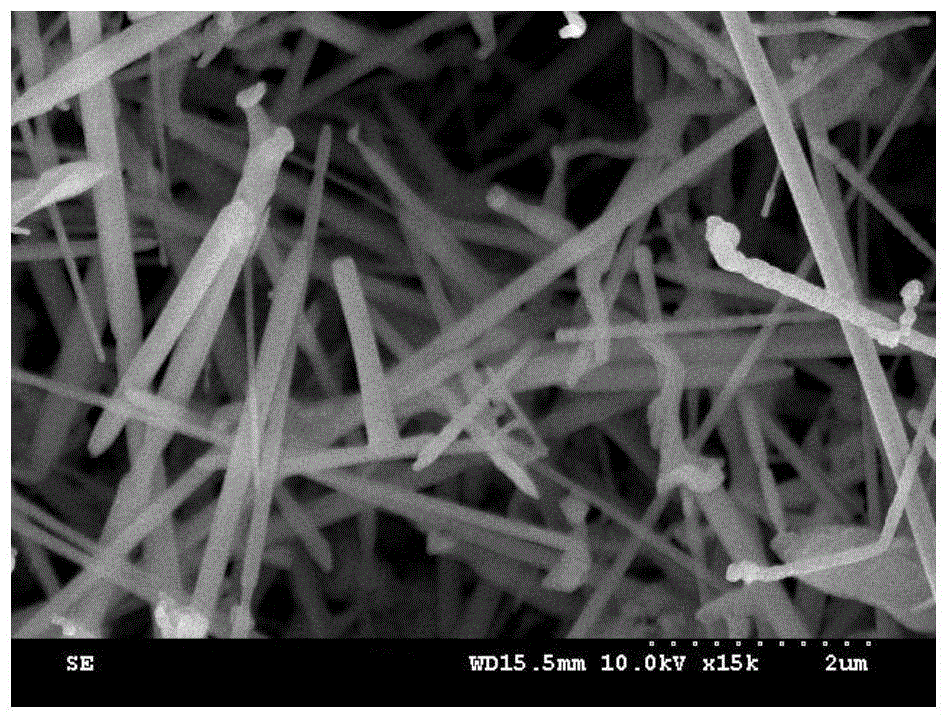

Embodiment 2

[0036] Step 1, preparing the precursor solution;

[0037] Weigh 250g of magnesium sulfate and 20g of Tween 80, and add 1000mL of deionized water. After the mixture was fully stirred for 0.5 hours in a pipeline type high-shear mixer, a well-dispersed transparent solution was obtained as a precursor solution.

[0038] Step 2, preparing the precursor;

[0039] Add 15g of phosphoric acid to the precursor solution, and feed in ammonia gas at a flow rate of 5L / h; the reaction temperature is 100°C, the rotation speed of the mixer is 10000rpm, and after 2 hours of reaction, filter to obtain the precursor.

[0040] Step 3, drying the precursor obtained in step 2 at 120° C. for 5 hours in a forced air drying oven, and the obtained white powder product is a nano-magnesium hydroxide material.

Embodiment 3

[0042] Step 1, preparing the precursor solution;

[0043] Weigh 250g of magnesium nitrate and 100g of Tween 80, and add 1000mL of deionized water. After the mixture was fully stirred for 0.5 hours in a pipeline type high-shear mixer, a well-dispersed transparent solution was obtained as a precursor solution.

[0044] Step 2, preparing the precursor;

[0045] Add 15g of phosphoric acid to the precursor solution, and feed in ammonia gas at a flow rate of 5L / h; the reaction temperature is 100°C, the rotation speed of the mixer is 10000rpm, and after 2 hours of reaction, filter to obtain the precursor.

[0046] Step 3, drying the precursor obtained in step 2 at 120° C. for 5 hours in a forced air drying oven, and the obtained white powder product is a nano-magnesium hydroxide material. In this example, because the added surfactant content is too high, a large amount of foam will be generated during the reaction, which is not conducive to the formation of the precursor, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com