Tyre body fitting drum

A drum body and drum tile technology, which is applied to tires, other household utensils, household utensils, etc., can solve problems such as energy waste, wrinkling at the mouth, and complex structure of the carcass fitting the drum, so as to achieve good rolling effect and good accumulation Effect of reduced thickness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the body bonding drum of the present invention is described in detail.

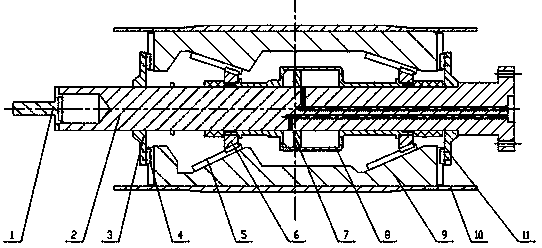

[0018] figure 1 It is the structural diagram of the carcass fitting drum. The carcass fitting drum of the present invention is mainly composed of a main shaft 2 and a drum body.

[0019] A left support disc 3 and a right support disc 11 are fixed on the main shaft 2, a hidden cylinder 8 that can slide on the main shaft 2 is arranged in the middle of the two support discs, and a cone 6 is respectively sleeved on the outer edge of the two ends of the hidden cylinder 8. A sealed air chamber is formed between the middle part of the cylinder 8 and the main shaft 2, and the piston 7 is fixed on the main shaft 2 to divide the sealed air chamber into two parts. The main shaft 2 is processed with an air passage hole, and the two air passage holes are respectively connected to the two parts of the sealed air chamber ; One end of the main shaft 2 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com