BOPP film capable of resisting crease and resisting cigarette packet deformation as well as preparation method thereof

A film and cigarette pack technology, applied in the field of anti-wrinkle and anti-cigarette pack deformation BOPP film and its preparation, can solve the problems of non-adherence, sticking, cigarette pack deformation, etc. The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

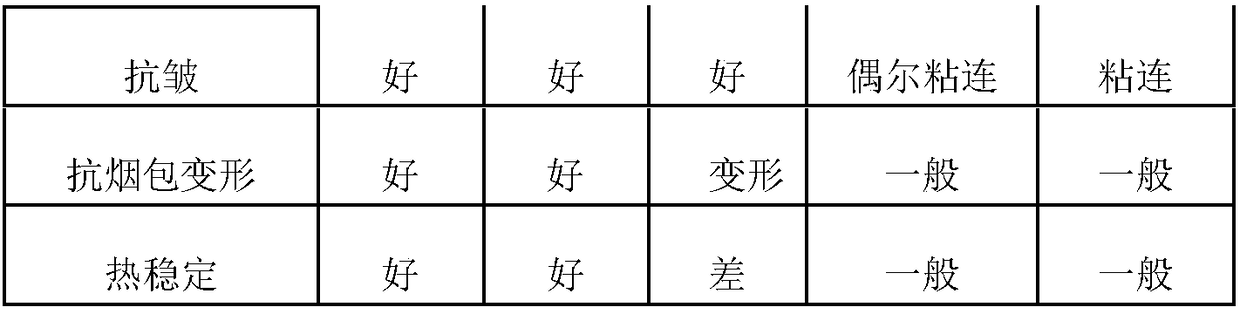

Examples

Embodiment 1

[0031] Raw material formula:

[0032] (1) Upper surface layer

[0033] Copolymer polypropylene 85 parts by weight

[0034] 12 parts by weight of slip agent masterbatch

[0035] 3 parts by weight of anti-adhesive masterbatch

[0036] The carrier of slip agent masterbatch and anti-adhesive masterbatch is polypropylene copolymer, the active ingredient of slip agent masterbatch is high-viscosity silicone, the concentration is 10%; the active ingredient of anti-adhesive masterbatch is synthetic resin, the concentration is 5%.

[0037] (2) core layer

[0038] 87 parts by weight of homopolymer polypropylene

[0039] 10 parts by weight of stiffening agent masterbatch

[0040] 3 parts by weight of antistatic agent masterbatch

[0041] The carrier of stiffening agent masterbatch and antistatic agent masterbatch is homopolymer polypropylene. The active ingredient of stiffener masterbatch is C 9 The active ingredients of the hydrogenated resin and antistatic agent masterbatch are c...

Embodiment 2

[0054] Raw material formula:

[0055] (1) Upper surface layer

[0056] Copolymer polypropylene 86 parts by weight

[0057] 11 parts by weight of slip agent masterbatch

[0058] 3 parts by weight of anti-adhesive masterbatch

[0059] The carrier of slip agent masterbatch and anti-adhesive masterbatch is copolymer polypropylene, the active ingredient of slip agent masterbatch is silicone resin, the concentration is 10%; the active ingredient of anti-adhesive masterbatch is silicon dioxide particles, The concentration is 5%.

[0060] (2) core layer

[0061] 87 parts by weight of homopolymer polypropylene

[0062] 10 parts by weight of stiffening agent masterbatch

[0063] 3 parts by weight of antistatic agent masterbatch

[0064] The carrier of stiffening agent masterbatch and antistatic agent masterbatch is homopolymer polypropylene. The active ingredient of stiffener masterbatch is C 9 The active ingredients of the hydrogenated resin and antistatic agent masterbatch ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com