Sea-island fibre and preparation method thereof

A technology of sea-island fiber and monofilament fineness, which is applied in fiber processing, melt spinning, conjugated synthetic polymer rayon, etc., to achieve the effects of improved economic efficiency, high coloring rate, and increased expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

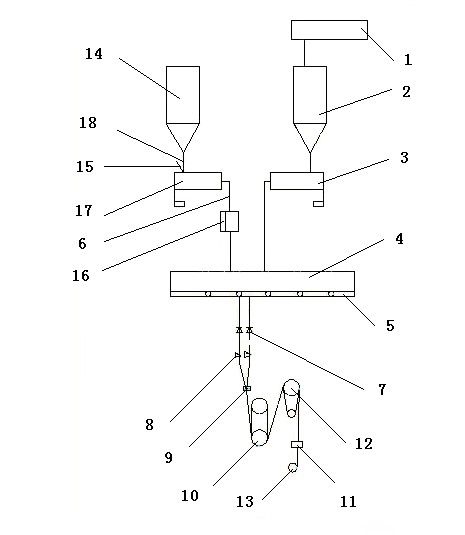

[0029] This embodiment provides a method for preparing PTT sea-island fibers, which is based on common composite spinning FDY production equipment, with PTT as the island component and COPET as the sea component, to prepare ultra-fine PTT long fibers with direct weaving ability.

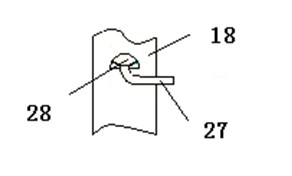

[0030] See attached figure 1 , which is a schematic diagram of a process flow for preparing PTT sea-island fibers provided in this embodiment; PTT slices are used as the first raw material. After the raw material is dried by the dryer 14, its moisture content is controlled at less than 20ppm, and the raw material is fed through the slices by its own weight. The pipeline 18 enters the island raw material screw extruder 17, and on the slice feeding pipeline of the feeding port of the screw extruder, a nitrogen inlet device 15 is provided, see the attached figure 2 , which is a structural schematic diagram of the nitrogen input device provided in this embodiment; on the PTT chip feed pipeline 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com