Method for self-calibrating zero position of fine and coarse machine of double-channel multi-polar rotary transformer

A resolver, dual-channel technology, applied in the field of electronics, can solve the problems of difficult operation, time-consuming and laborious, and achieve the effect of simple and effective circuit, low cost, and fast zero-position self-calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

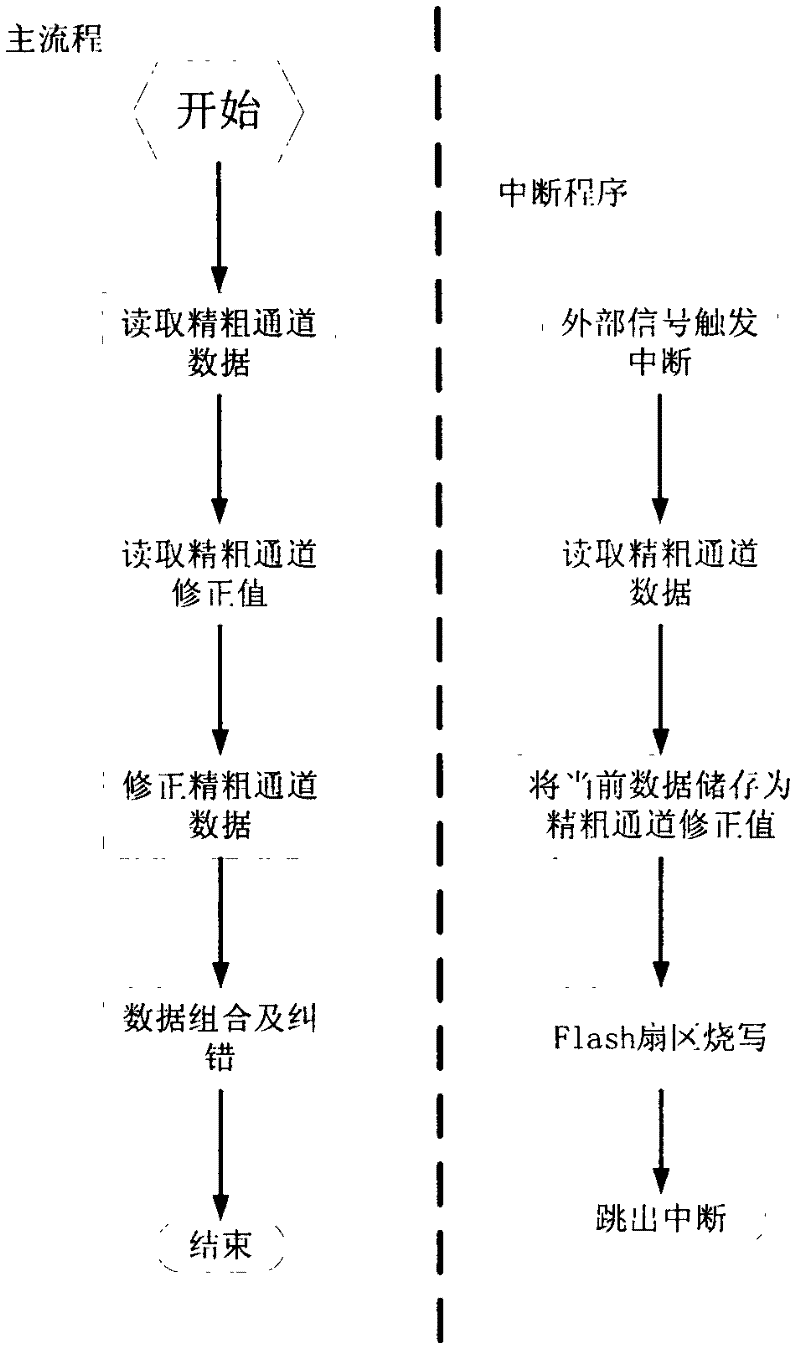

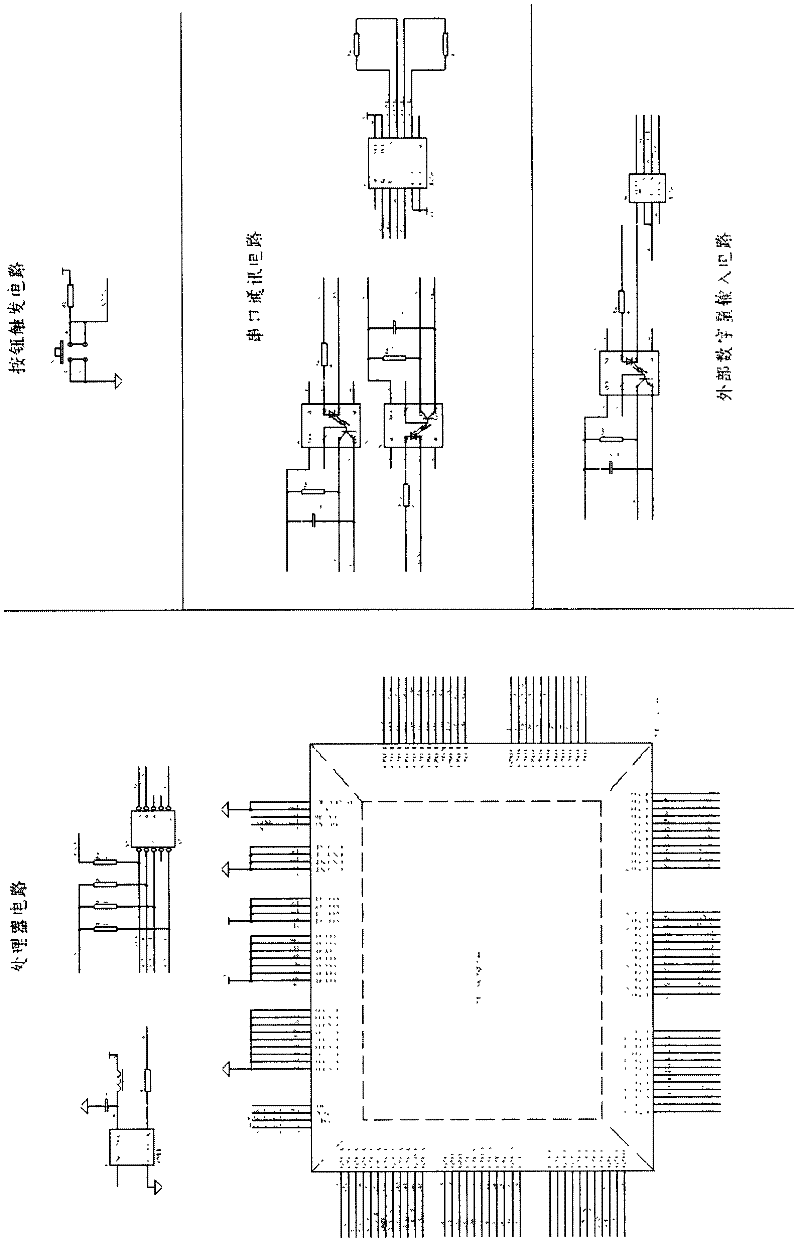

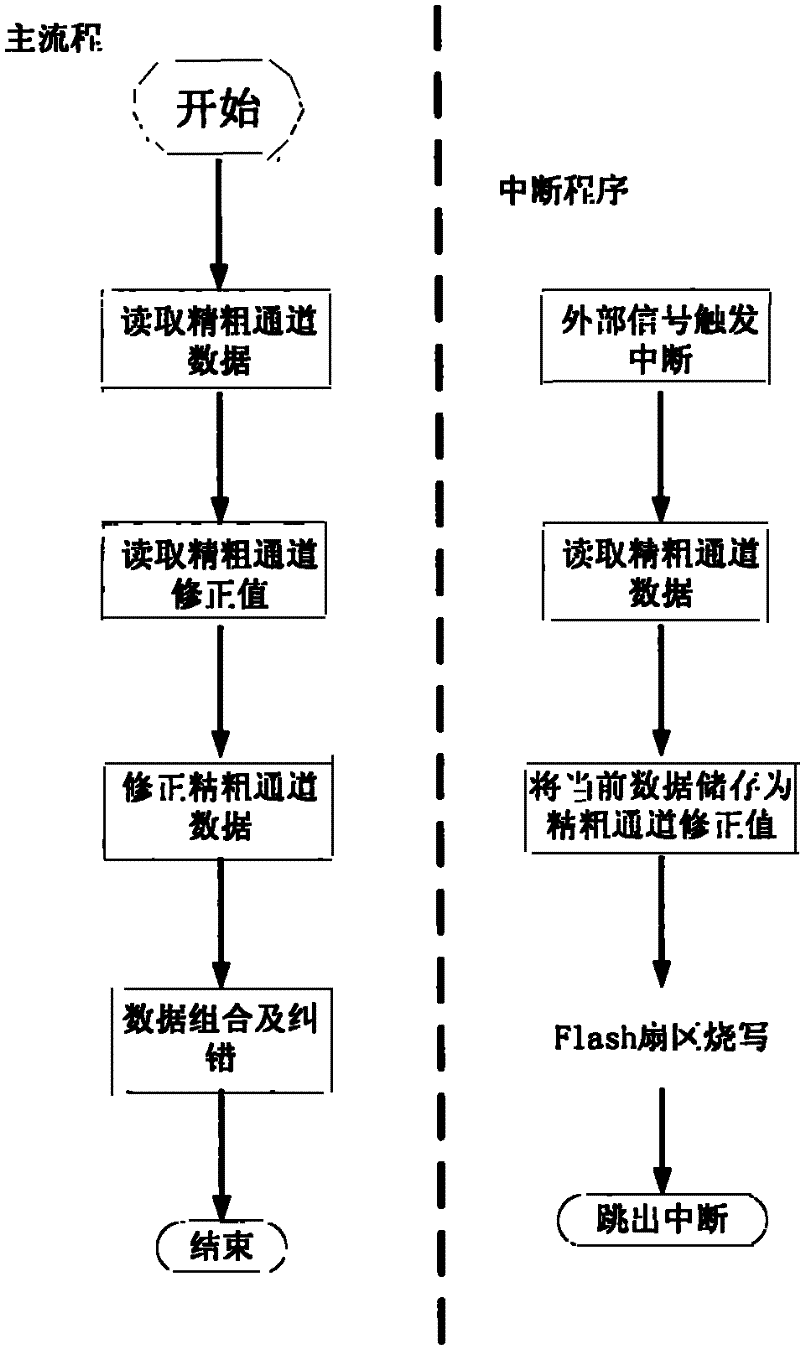

[0026] The embodiment of the present invention relies on the microprocessor technology and uses non-volatile memory for design, and its specific technical solution consists of two parts. The first part is the main process, and its steps are as follows: first, the microprocessor reads the code value of the current resolver fine-coarse channel from the external components; secondly, the processor reads the current resolver fine-coarse channel from the specified location of the non-volatile memory Then use the correction value to correct the code value of the fine and coarse channels respectively; finally, the corrected code value is used as the input of the combined error correction algorithm for corresponding processing. The second part is the update process of the correction value, and its steps are as follows: First, the processor enters the interrupt program ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com