White glaze, boundary-free ceramic tile containing white glaze and production method of boundary-free ceramic tile

A technology of ceramic tiles and boundaries, applied in the field of ceramics, can solve the problems of inability to achieve ceramic decoration effects, large-scale production, and poor stability, and achieve the effects of reducing printing defects, reducing overall manufacturing costs, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

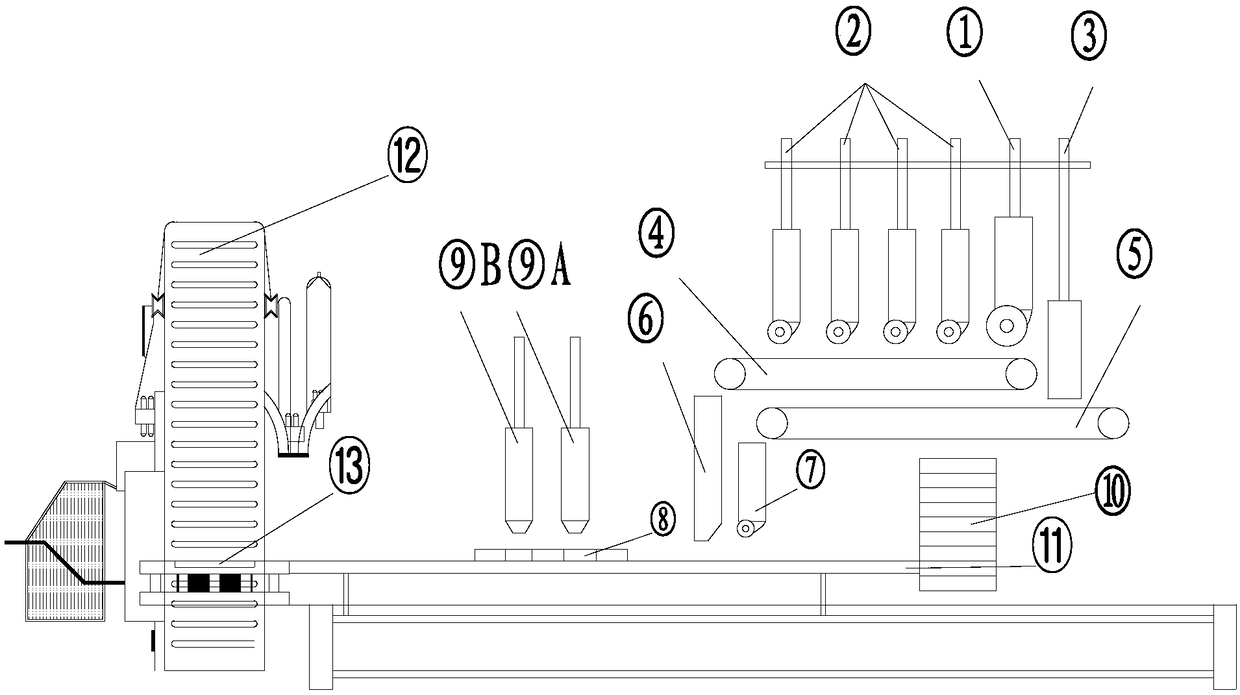

[0048] The present invention will be described in further detail below in conjunction with embodiment and accompanying drawing:

[0049] The white glaze of the whole body borderless ceramic tile includes the following raw materials by weight percentage:

[0050] Opacifier 75% Opacifier Frit 20% Clay 5%.

[0051] The opacifying agent is one or a combination of tin oxide, zirconium oxide, titanium oxide, cerium oxide, and ultrafine zirconium silicate.

[0052] The opacified frit adopts one or a combination of zirconium white opacified frit, zirconium-titanium opacified frit, phosphorus-zirconium composite opacified frit.

[0053] The preparation method of the whole-body borderless ceramic brick by rubber roller printing comprises the following steps:

[0054] (1) After the green body is formed, the surface of the green body is polished with a sponge material;

[0055] (2) After the polished green body has passed through the drying process, use rubber rollers to print white gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com