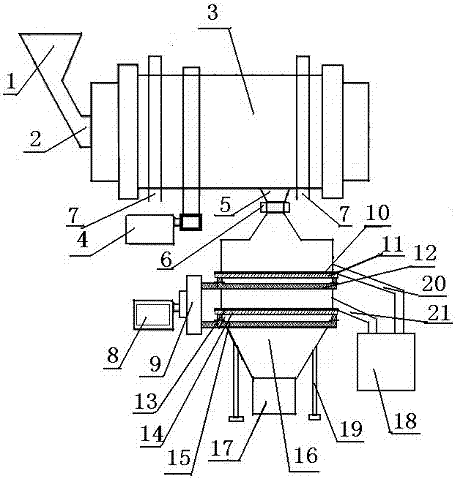

Ceramic ball mill with discharging classifying screen

A grading screen and ceramic ball technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of easily damaged screen materials and hoppers, and achieve the effect of reducing labor intensity, reducing impact and improving screening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The specific embodiment of the ceramic ball mill with discharge classifying screen of the present invention is as follows:

[0026] 1. Before use, close the gate 6, pour the ceramic raw material from the hopper 1 into the drum 3 through the feeding port 2, and then start the transmission mechanism 4 to start grinding the ceramic raw material.

[0027] 2. When the grinding fineness meets the required requirements, start the vibration mechanism 9, open the gate 6, and the ground material falls into the first-stage sieve plate 11 of the grading screen device 16, and the first-stage sieve plate 11 screens the material The under-sieve material passing through the sieve hole of the first-stage sieve plate 11 falls on the second-stage sieve plate 14, and the over-sieve material trapped on the sieve surface falls into the coarse material collection box through the first-stage sieve opening 20. 18 in.

[0028] 3. The material falling from the sieve hole of the first-stage sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com