Production equipment for extracting cotton protein from cottonseed meal

A production equipment and cotton protein technology, applied in the application, cocoa, grain processing and other directions, can solve the problems of affecting the quality of cotton protein, the grinding force is large, and the grinding force is difficult to control, so as to reduce damage to the composition of cotton protein and reduce work Requirements, the effect of saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

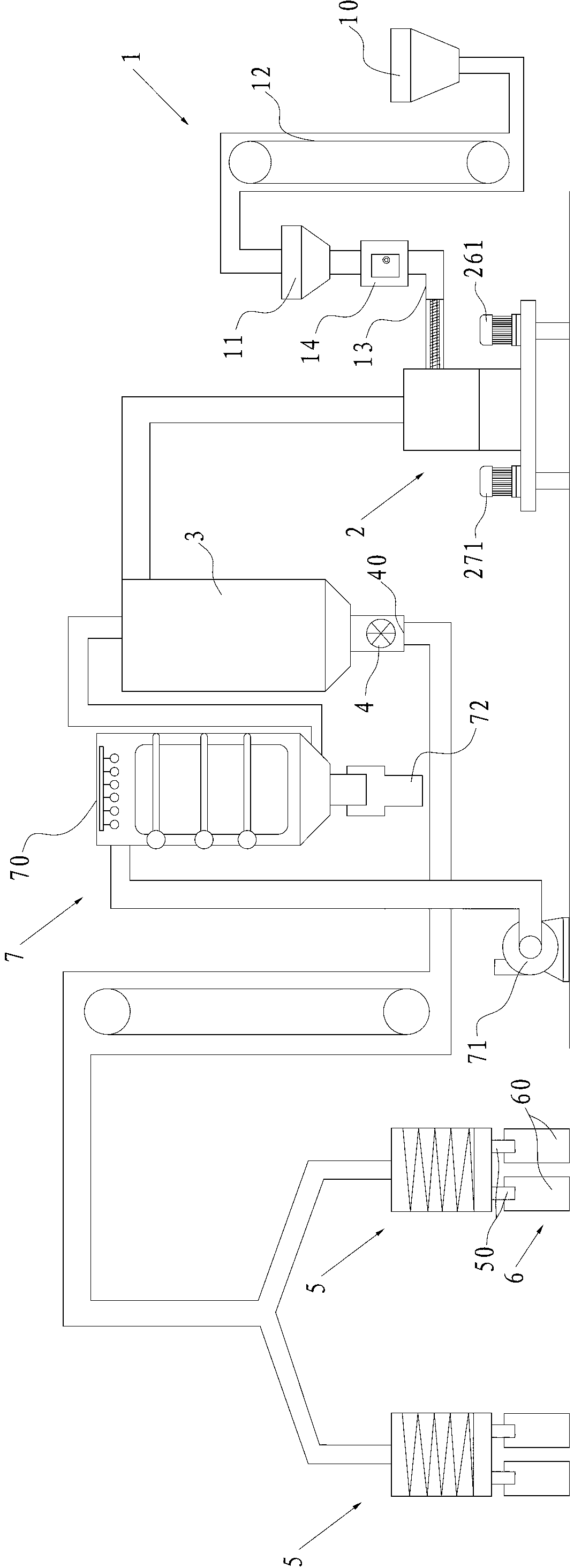

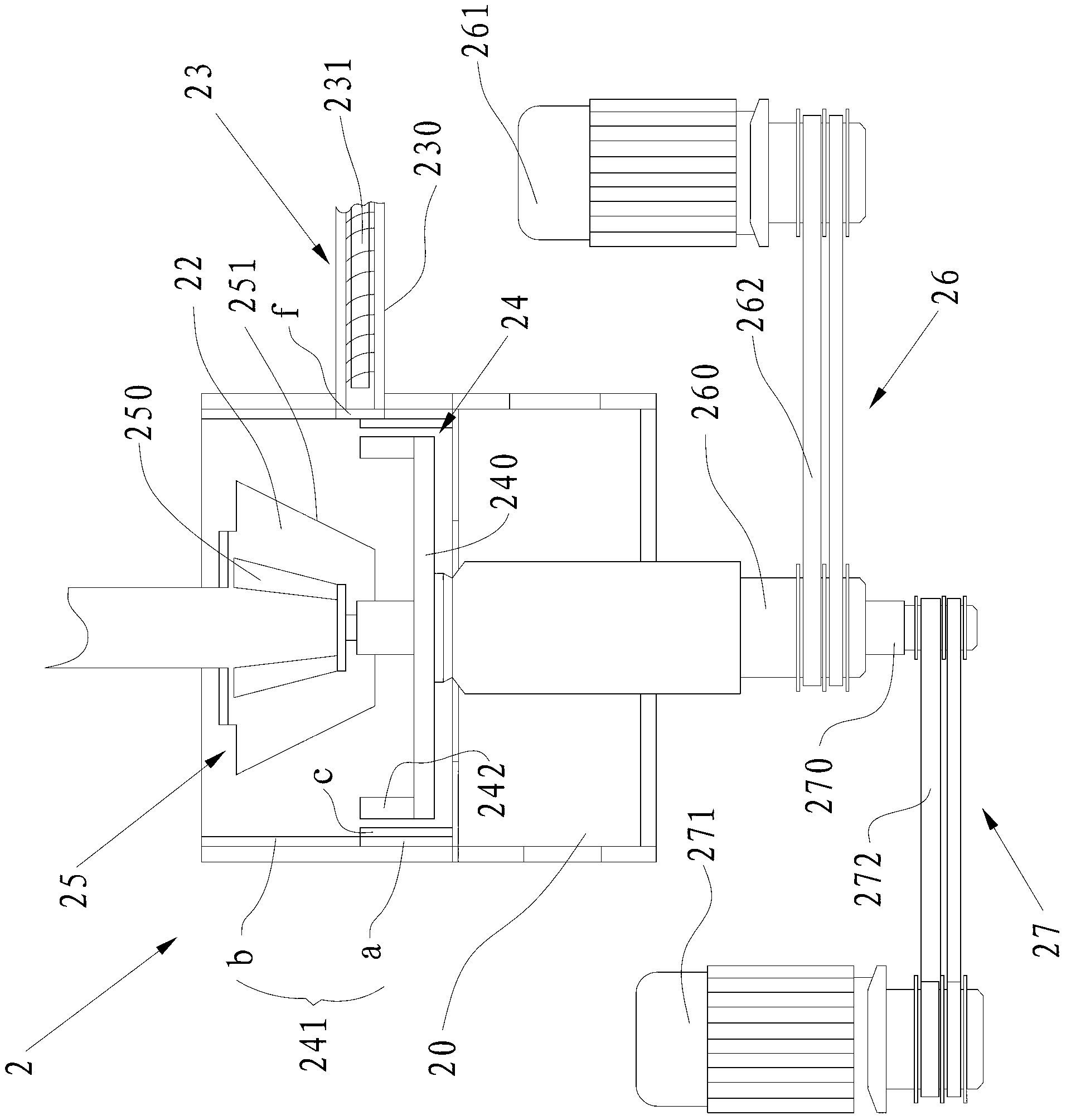

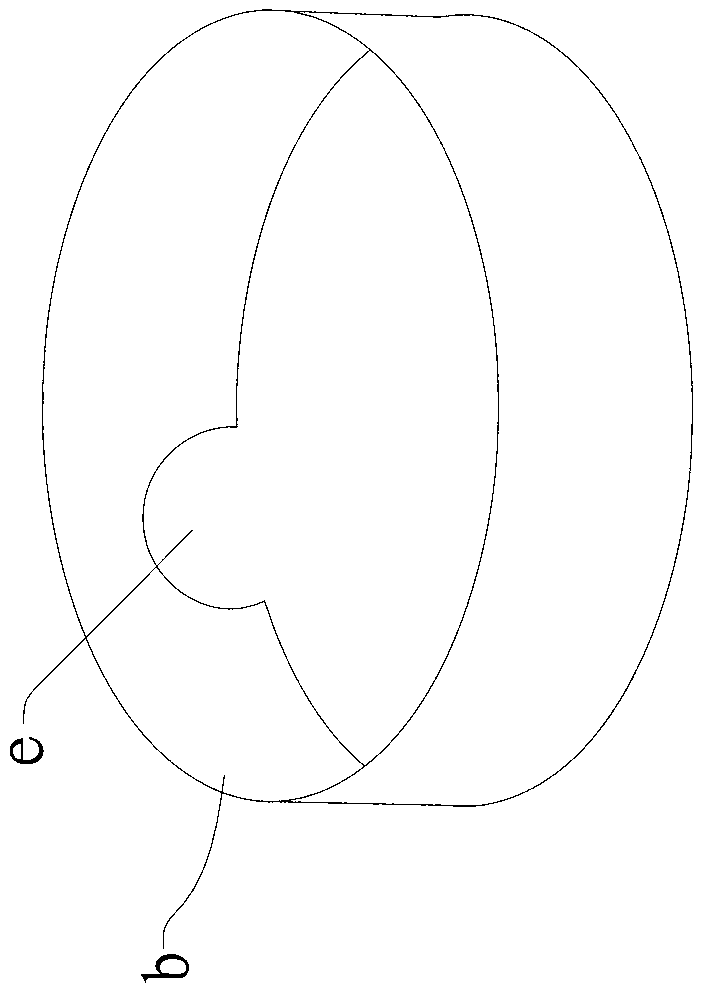

[0024] Such as Figure 1 to Figure 5 As shown, the production equipment for extracting cotton protein from cotton meal includes a feeding mechanism 1, a particle crushing mechanism 2, and an intermediate silo 3, which are used to suck the crushed cotton meal from the particle crushing mechanism 2 to the intermediate material. The air locker 4 in the warehouse 3, the screening mechanism 5 for screening cotton protein and crude fiber, and the material receiving mechanism 6, wherein the air outlet 40 of the air locker 4 is connected with the screening mechanism 5, and the screening mechanism 5 There are at least two discharge openings 50 at the bottom of the bottom, and the receiving mechanism 6 includes collection containers 60 corresponding to and communicating with the discharge openings 50 respectively. The collection containers 60 respectively collect cotton protein and crude fibers. The vortex crushing mechanism (hereinafter all replaced by this name) has an air inlet cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com