Purification method of polyvinyl alcohol resin

A technology of polyvinyl alcohol resin and ethanol, which is applied in the field of purification of polyvinyl alcohol resin as a pharmaceutical excipient, and can solve the problems of polyvinyl alcohol resin color and performance changes, agglomeration, consumption of large steam and dilution gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

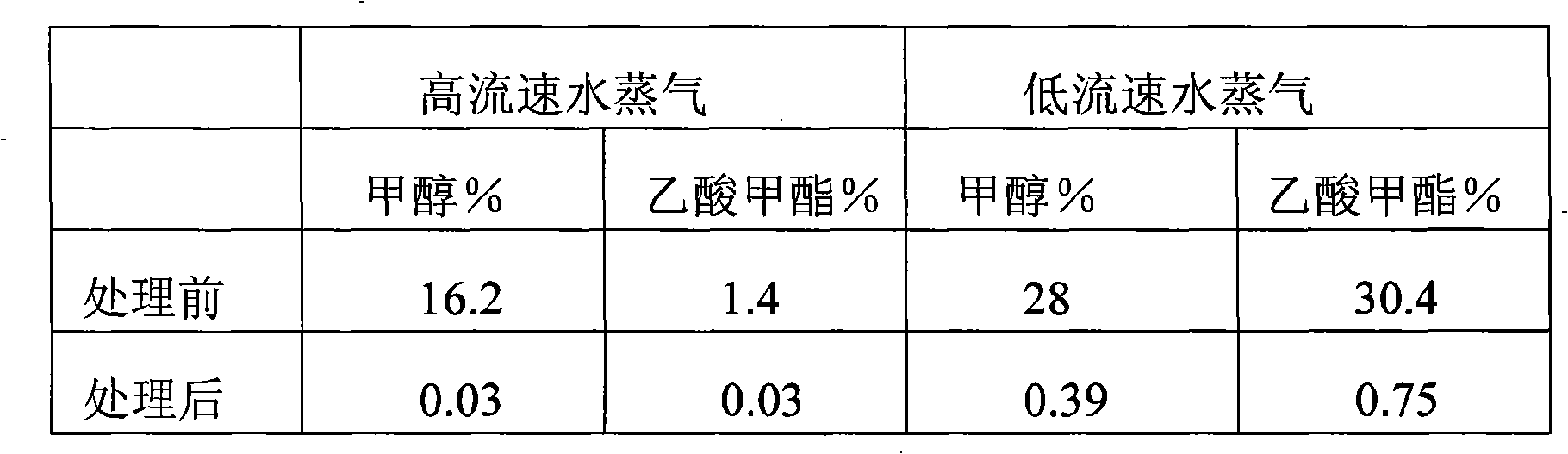

Image

Examples

Embodiment 1

[0029] Stir the mixed solvent of ethanol and water, wherein the mass percentage of ethanol is 60%, slowly add polyvinyl alcohol resin, stir for 2.5 hours, make the polyvinyl alcohol resin fully swell, continue to add ethanol to make the final concentration of ethanol in the mixed solvent The mass percentage is 75%, continue to stir to precipitate the polyvinyl alcohol resin, vacuum filter, and separate the solid material from the solvent; the separated polyvinyl alcohol resin is vacuum-dried with a vacuum degree of minus 0.15Mpa. The dried material is ground and the particle size is controlled within 200-300um. The organic solvent and inorganic salt residue detection results of the polyvinyl alcohol resin prepared by the method are shown in Table 3 below.

[0030] Table 3 The organic solvent and inorganic salt residue detection data of Example 1

[0031] Industrial Grade Polyvinyl Alcohol Resin

[0032] ethanol

[0033] As can be seen from the table, imp...

Embodiment 2

[0035] Stir the mixed solvent of ethanol and water, wherein the mass percentage of ethanol is 65%, slowly add polyvinyl alcohol resin, stir for 2.5 hours, make the polyvinyl alcohol resin fully swell, continue to add ethanol to make the final concentration of ethanol in the mixed solvent The mass percentage is 80%, continue to stir to precipitate the polyvinyl alcohol resin, and vacuum filter to separate the solid material from the solvent; the separated polyvinyl alcohol resin is vacuum-dried with a vacuum degree of minus 0.15Mpa. The dried material is ground to control the particle size within 200-300um. The organic solvent and inorganic salt residue detection results of the polyvinyl alcohol resin prepared by the method are shown in Table 4 below.

[0036]Table 4 The organic solvent and inorganic salt residue detection data of Example 2

[0037] Industrial Grade Polyvinyl Alcohol Resin

Embodiment 3

[0039] Stir the mixed solvent of ethanol and water, wherein the mass percentage of ethanol is 75%, slowly add polyvinyl alcohol resin, stir for 2.5 hours, make the polyvinyl alcohol resin fully swell, continue to add ethanol to make the final concentration of ethanol in the mixed solvent The mass percent content is 80%, continue stirring to vacuum-dry the isolated polyvinyl alcohol resin, the polyvinyl alcohol resin is precipitated, and vacuum suction is used to separate the polyvinyl alcohol resin from the solvent, and part of the inorganic salt is taken away in the solvent; separation The obtained polyvinyl alcohol resin is vacuum-dried, and the vacuum degree is negative 0.12Mpa. The dried material is ground to control the particle size within 200-300um. The detection results of the organic solvent and inorganic salt residues of the polyvinyl alcohol resin prepared by the above method are shown in Table 5 below.

[0040] Table 5 The organic solvent and inorganic salt residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com