Traversing reverse circulating drilling method of horizontal directional drilling pipeline and special drilling bit

A technology of horizontal directional drilling and reverse circulation, applied in directional drilling, drilling equipment and methods, drill bits, etc., can solve problems such as the crossing construction of large-diameter horizontal directional drilling pipelines, so as to reduce the cost of equipment entry and exit, and reduce the amount of use. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

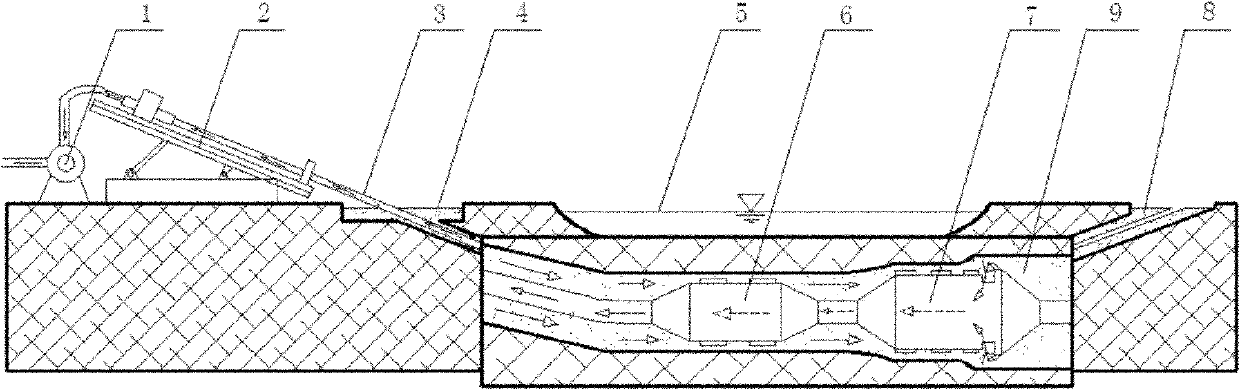

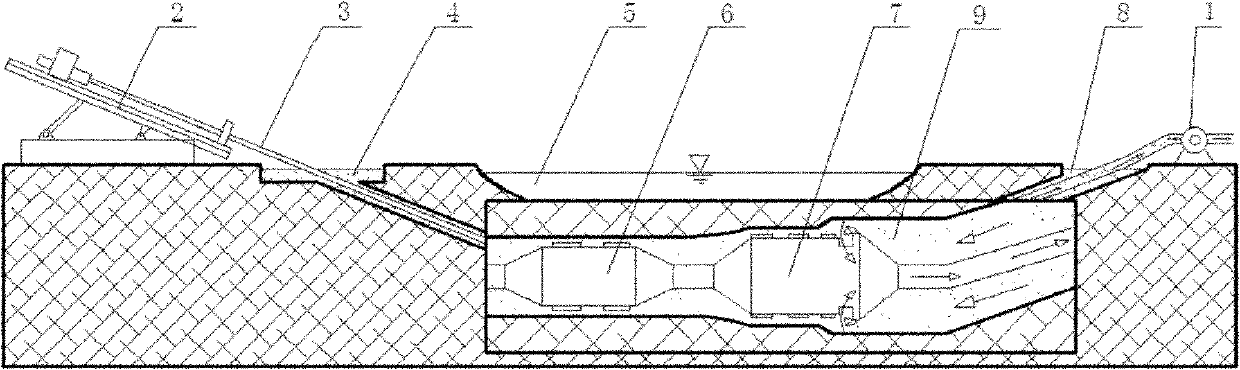

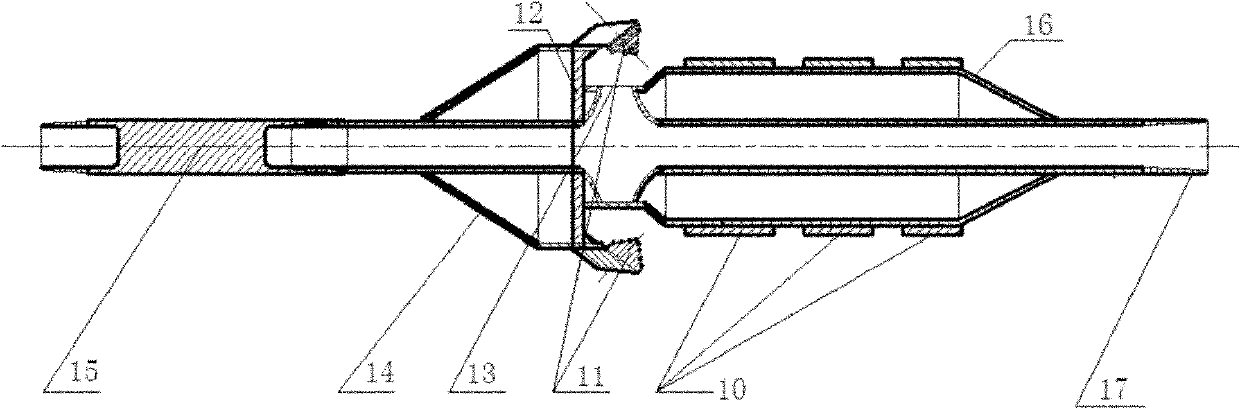

[0030] Such as figure 1 , figure 2 As shown, the horizontal directional drilling pipe crossing reverse circulation drilling method provided by the present invention is based on the traditional drilling mud circulation, by changing the supporting equipment and adopting a new structure of the drill bit, the mud in the drilling process is realized according to the mud pool→drilling ring In this process, the drill pipe 3 of the drilling rig 2 enters the drilling annular space 9 through the entry pit 4, and the drilling annular space 9 The other end is an unearthed pit 8, and the drill pipe 3 of the drilling rig 2 is provided with a centralizer 6, and the drill pipe 3 is connected with the reaming bit 7 through the drill pipe joint, and both the inside of the drill pipe and the reaming bit are hollow cavities. The drill bit 7 is provided with a slag suction port 13 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com