Oilfield automatic feed descaling and dewaxing device with movable lifting mechanism

A lifting mechanism and automatic feeding technology, which is applied in the direction of cleaning equipment, wellbore/well components, earthwork drilling and production, etc., can solve the problems of inconvenient operation, low efficiency of descaling and wax removal, inability to deposit wax, oil and scale removal and other problems, to achieve the effect of easy operation and use, and improve the effect of descaling and wax removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

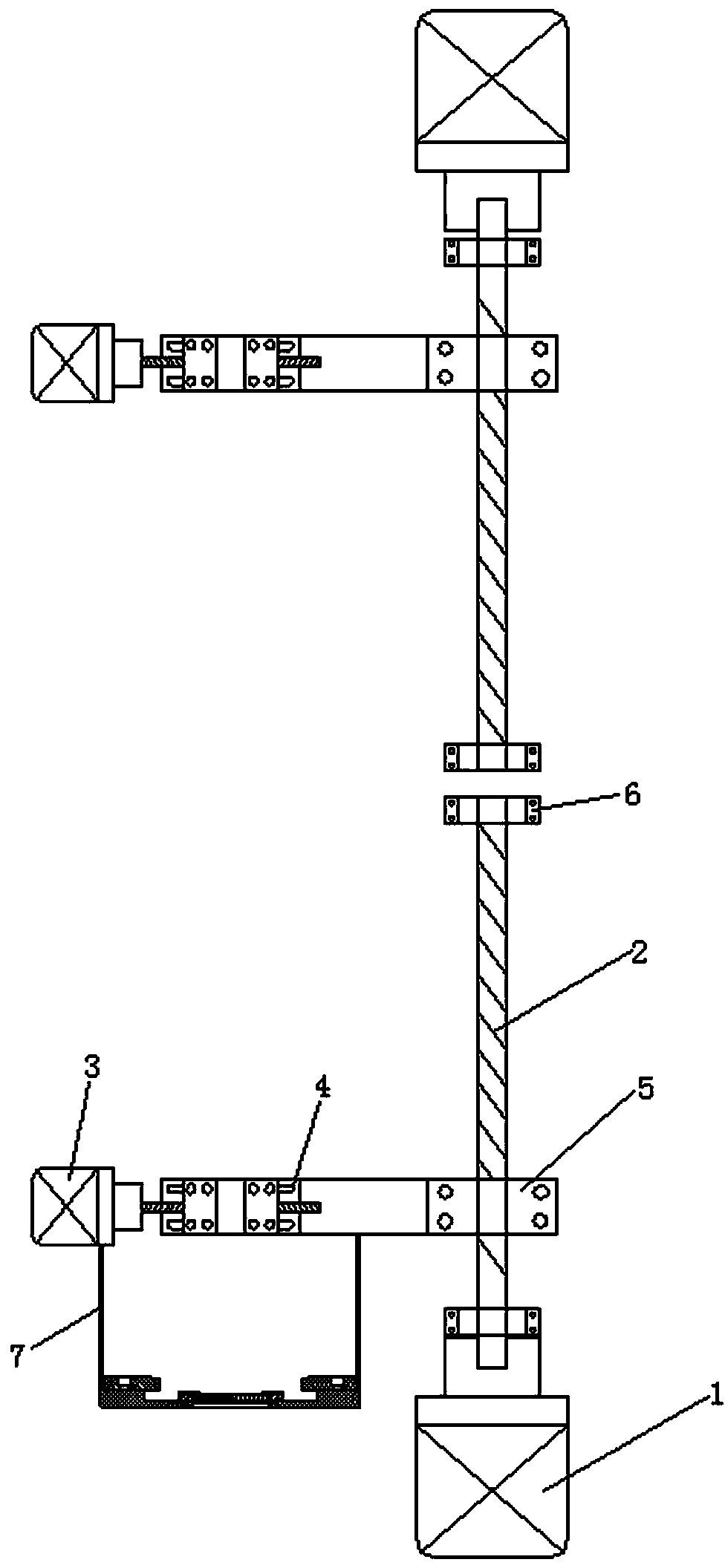

[0009] Such as figure 1 As shown, the oil field automatic feeding descaling and wax removal device with a mobile lifting mechanism includes a blade assembly, a rubber scraper assembly and a mobile lifting mechanism. The mobile lifting mechanism includes two sets of symmetrically arranged moving assemblies, each of which moves The assembly includes a first motor 1, a lead screw 2 longitudinally connected to the first motor 1, a second motor 3, and a compression device 4 transversely connected to the second motor 3, and the compression device 4 passes through a nut seat 5 is connected with one end of the lead screw 2, wherein the pressing device 4 is fixedly connected with the nut of the lead screw 2, the other end of the lead screw 2 is provided with a bearing seat 6, and the first motor 1 drives the lead screw 2 to make The spiral action drives the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com